Auxiliary hoisting device for bridge construction

A bridge construction and auxiliary crane technology, which is applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of increased construction safety risks, construction personnel injured, poor risk factor, etc., to increase the coverage of hoisting, The effect of ensuring stability and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

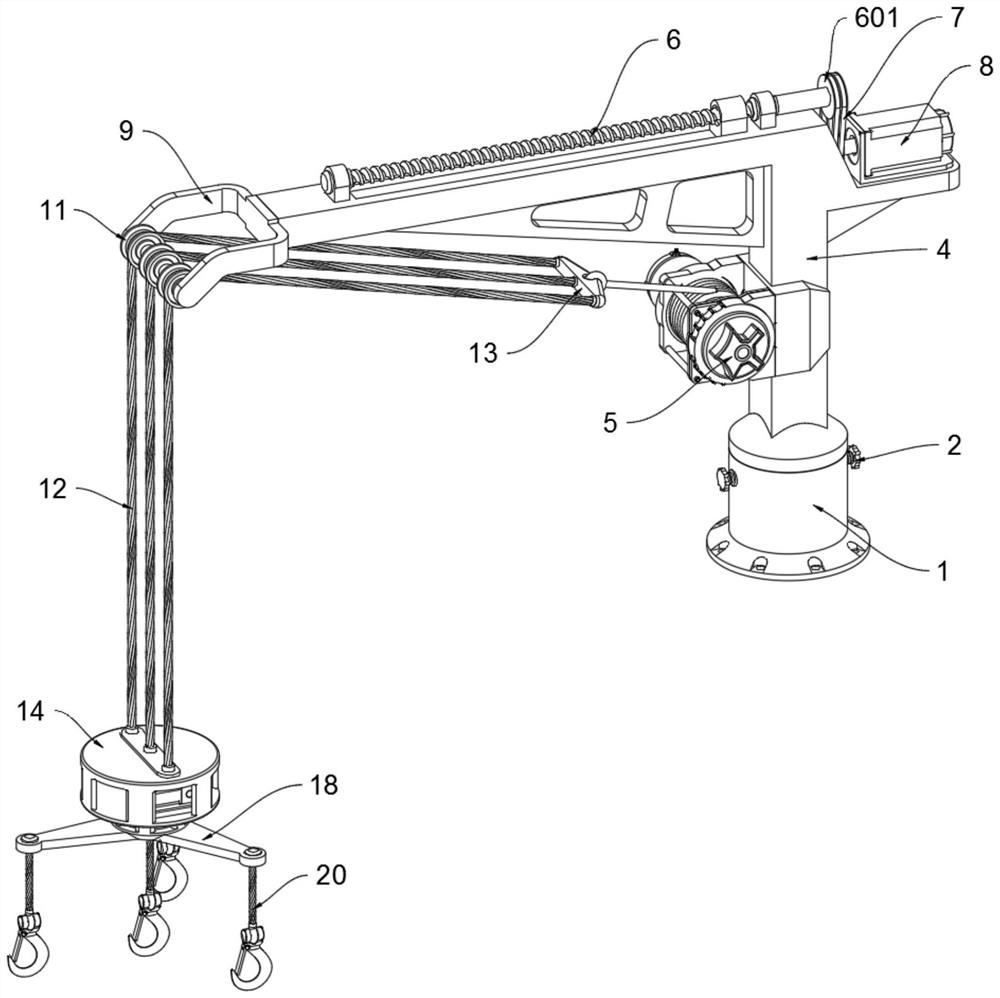

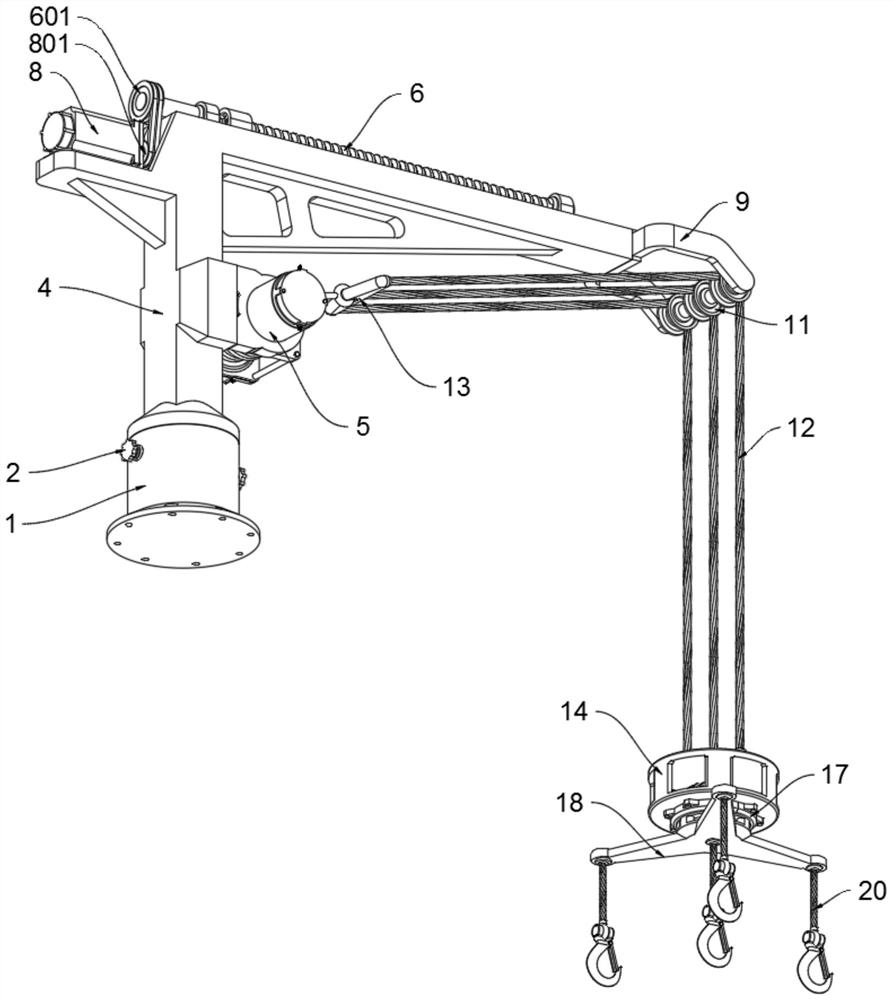

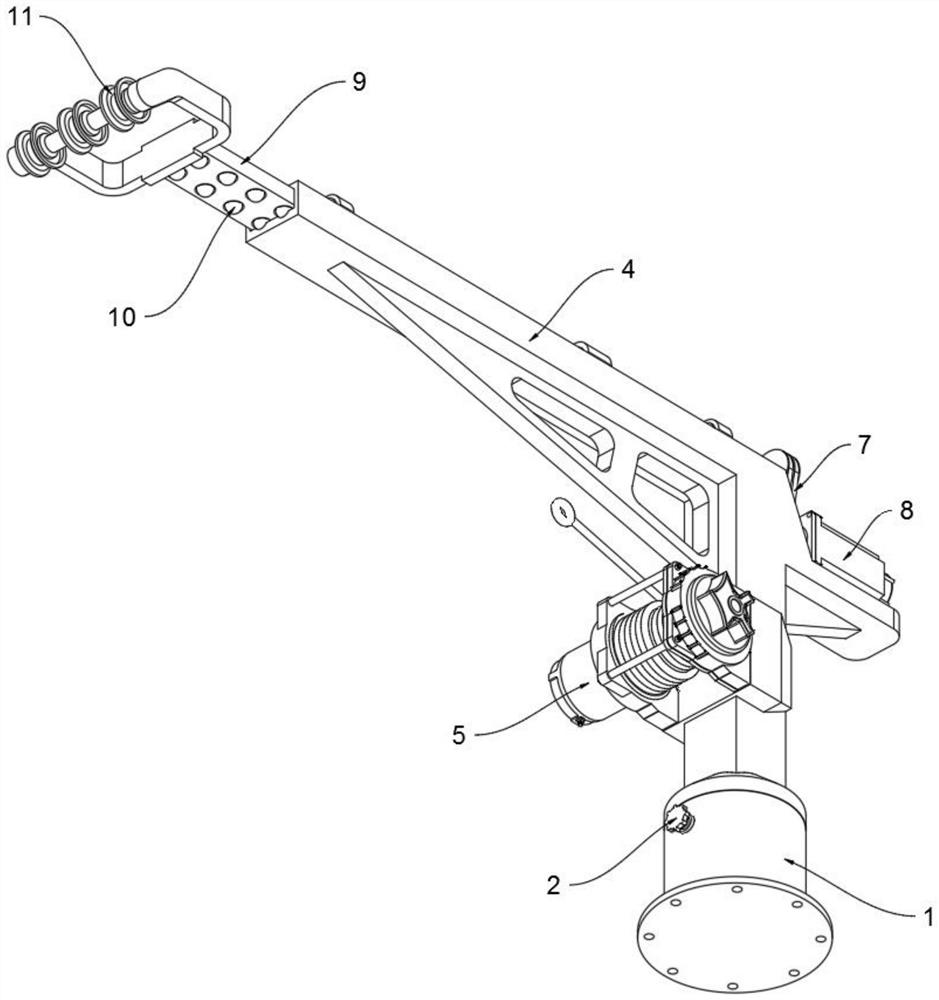

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides an auxiliary hoisting device for bridge construction, comprising a base 1, a main frame body 4, a screw rod 6, an adjusting motor 8, a movable hoisting rod 9, a hoisting rope 12, a limit ring sleeve 17 and a hoisting frame 18; the base 1 The interior is a hollow structure, and the plane bearing 3 is installed inside the base 1; the bottom of the main frame body 4 is connected to the inside of the base 1, and a winch 5 is fixedly installed on the outside of the main frame body 4, and the hoist machine 5 is connected to the external control circuit; the main frame body 4. There are a number of limit grooves 401 on the outer side of the bottom in a circular shape. The outer side of the bottom of the main frame body 4 is rotated and fitted to the inner wall of the base 1, and the bottom of the main frame body 4 is pressed on the top of the plane bearing 3, and the left and right sides of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com