Fir powder subcritical water liquefaction method and biomass oil thereof

A subcritical water and biomass oil technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of slow reaction speed, low conversion rate, etc. Effective use of the effect

Active Publication Date: 2020-09-15

廖益强

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Existing biomass liquefaction methods involve high temperature and high pressure, highly toxic and volatile or

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] (1) Experimental materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

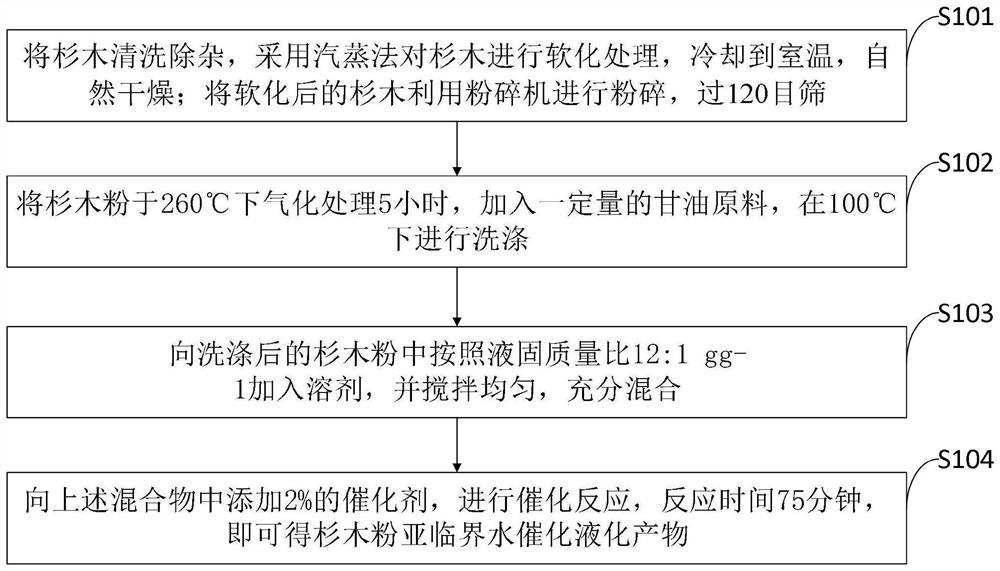

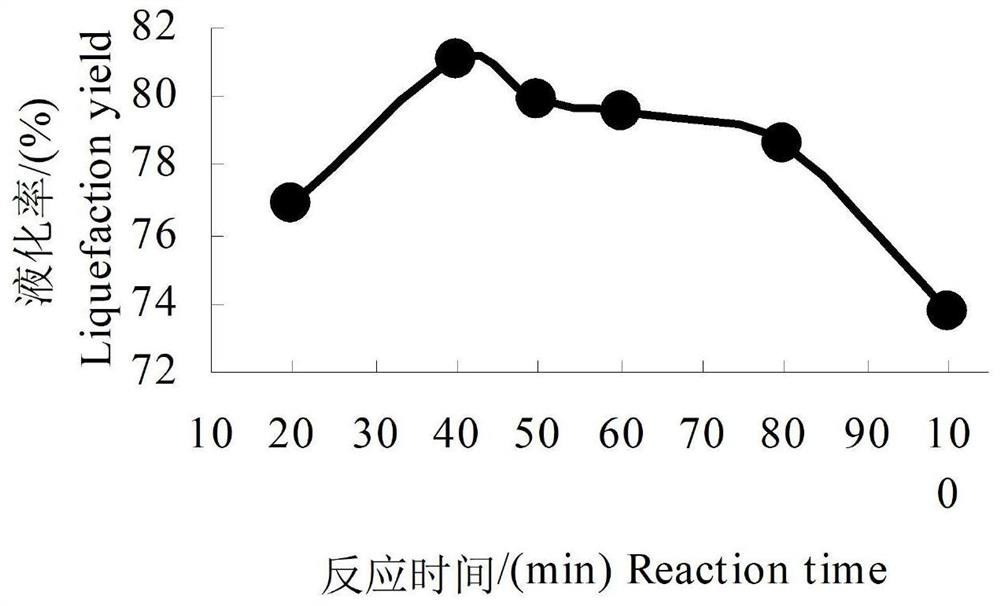

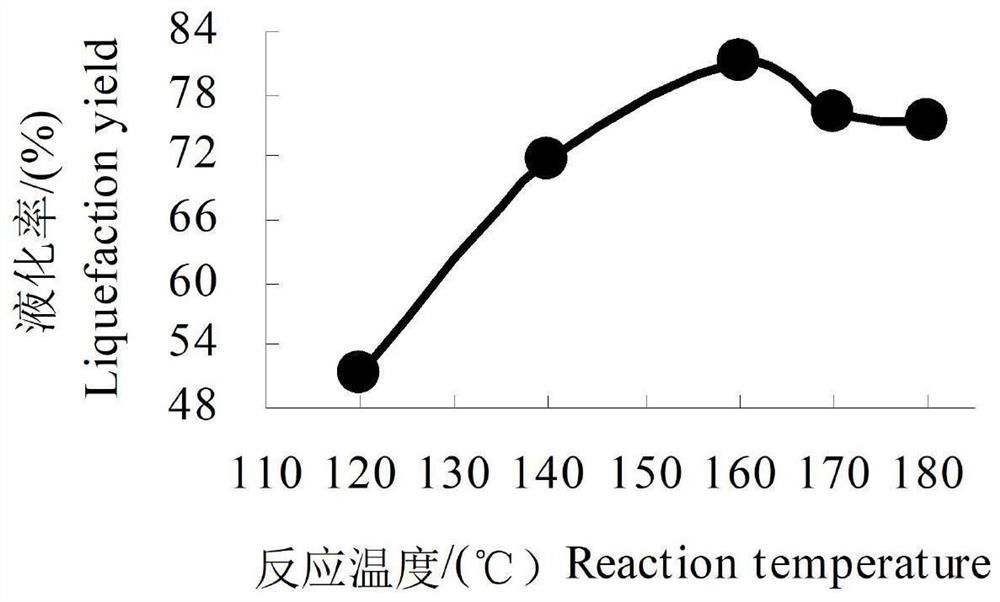

The invention belongs to the technical field of biomass liquefaction, and discloses a fir powder subcritical water liquefaction method and a biomass oil thereof. By using Chinese fir powder as a raw material, subcritical water as a reaction medium and an ionic liquid as a reaction catalyst, catalytic liquefying is performed in a high-pressure reaction kettle to prepare the biomass oil, optimal values of four factors including reaction temperature, reaction time, catalyst dosage and liquid-solid mass ratio which influence the liquefaction rate of the fir powder are obtained, an infrared spectrometer is adopted to analyze surface functional groups of the raw material, liquefaction residues and the fir powder biomass oil, and a gas chromatograph-mass spectrometer is adopted to analyze the chemical composition of the fir powder biomass oil. Subcritical water and the ionic liquid are organically combined to replace traditional wood liquefying agents such as phenols, polyols and liquid acid/alkali to be used in the wood liquefying process. By analyzing the liquefaction mechanism, the synergistic catalytic effect of the liquefying agent and the regulation and control mechanism of liquefaction product distribution, the scientific significance of the method is obvious, and meanwhile, the method has a good application prospect.

Description

technical field [0001] The invention belongs to the technical field of biomass liquefaction, and in particular relates to a fir powder subcritical water liquefaction method and biomass oil thereof. Background technique [0002] At present, the existing technologies commonly used in the industry are as follows: [0003] Biomass such as wood is a renewable carbon resource that can be converted into solid, liquid, and gaseous fuels and chemicals. It has the characteristics of abundant reserves, carbon sequestration, less energy consumption for processing, less environmental pollution, and can be naturally degraded and recycled. The comprehensive development and utilization of wood and other biomass resources has become a key development area of the country. Scholars at home and abroad have done a lot of research on the liquefaction of wood and other biomass, mainly in two aspects. Firstly, under high temperature and high pressure, the pyrolysis liquefaction of biomass requ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G1/00C10G1/08C10L1/00

CPCC10G1/00C10G1/083C10L1/00C10G2300/1011

Inventor 廖益强

Owner 廖益强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com