Preparation method of novel synthetic fiber multifunctional leveling agent

A synthetic fiber, multi-functional technology, applied in the field of printing and dyeing auxiliaries, can solve the problems of low linear density, poor levelness, increased specific surface area, etc., and achieve the effects of uniform dye distribution, good retardation, and increased voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

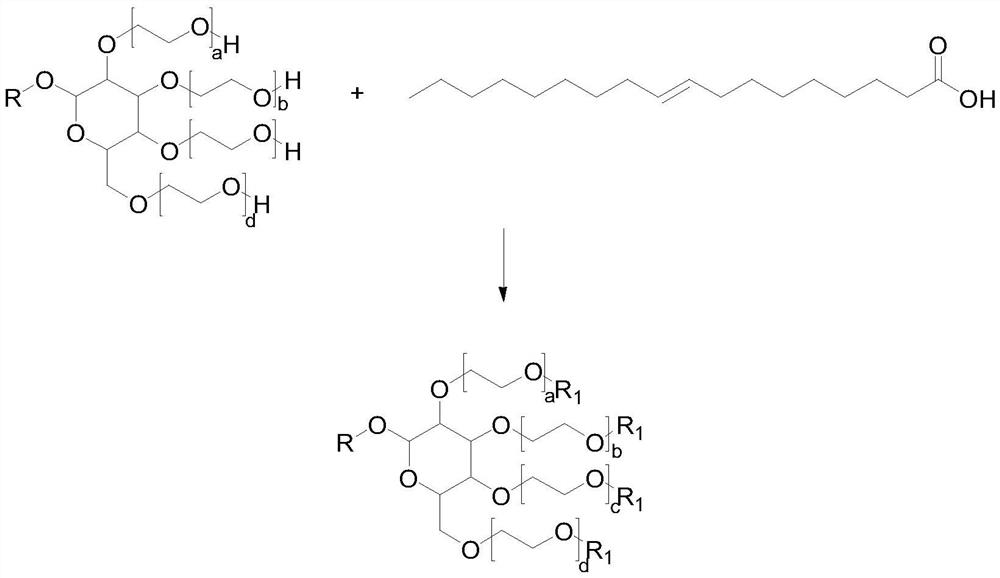

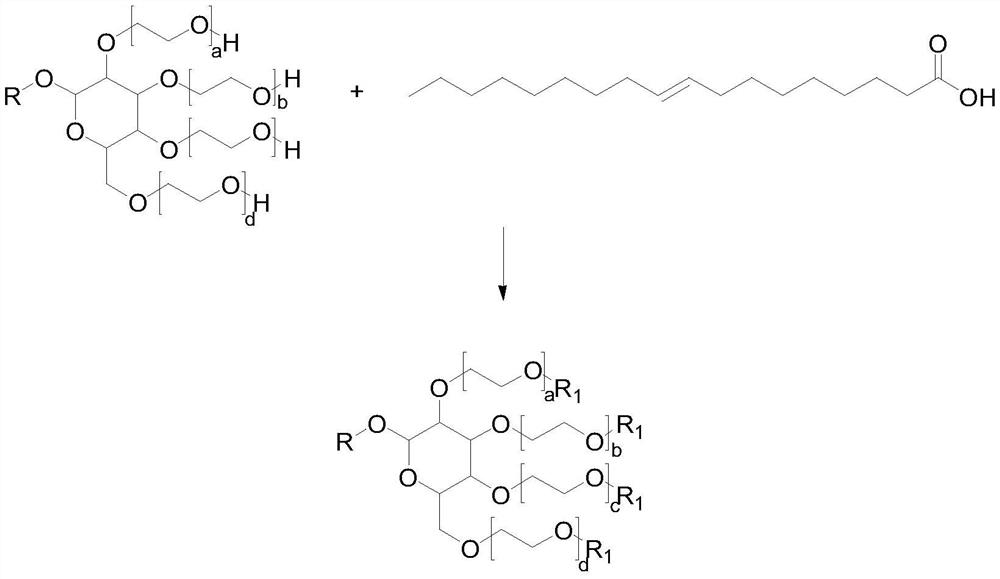

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Add 74 parts of alkyl glycoside polyoxyethylene ether, 28 parts of oleic acid, and 0.3 part of p-toluenesulfonic acid into the reaction vessel, raise the temperature to 130°C, turn on the vacuum, and keep the vacuum at -0.095MPa for 6 hours. , the temperature is lowered to below 50°C, the vacuum is turned off, and then the material is discharged to obtain alkyl glycoside polyoxyethylene ether oleate;

[0018] 20 parts of alkyl glycoside polyoxyethylene ether oleate, 10 parts of carrier, 4 parts of anionic surfactant, 10 parts of solvent, and 50 parts of water are put into a reaction vessel, stirred evenly, and discharged to obtain a new synthetic fiber multifunctional homogeneous dye.

Embodiment 2

[0019] Example 2: Add 78 parts of alkyl glycoside polyoxyethylene ether, 30 parts of oleic acid, and 0.5 part of p-toluenesulfonic acid into the reaction vessel, raise the temperature to 130°C, turn on the vacuum, and the vacuum degree is -0.095MPa. After 6 hours of heat preservation and reaction , the temperature is lowered to below 50°C, the vacuum is turned off, and then the material is discharged to obtain alkyl glycoside polyoxyethylene ether oleate;

[0020] 20 parts of alkyl glycoside polyoxyethylene ether oleate, 8 parts of carrier, 6 parts of anionic surfactant, 8 parts of solvent, and 52 parts of water are put into a reaction vessel, stirred evenly, and discharged to obtain a new synthetic fiber multifunctional homogeneous dye.

Embodiment 3

[0021] Example 3: Add 75 parts of alkyl glycoside polyoxyethylene ether, 25 parts of oleic acid, and 0.5 part of p-toluenesulfonic acid into the reaction vessel, raise the temperature to 130°C, turn on the vacuum, and keep the vacuum at -0.09MPa for 6 hours. , the temperature is lowered to below 50°C, the vacuum is turned off, and then the material is discharged to obtain alkyl glycoside polyoxyethylene ether oleate;

[0022] 20 parts of alkyl glycoside polyoxyethylene ether oleate, 5 parts of carrier, 5 parts of anionic surfactant, 5 parts of solvent, and 50 parts of water are put into a reaction vessel, stirred evenly, and discharged to obtain a new synthetic fiber multifunctional homogeneous dye.

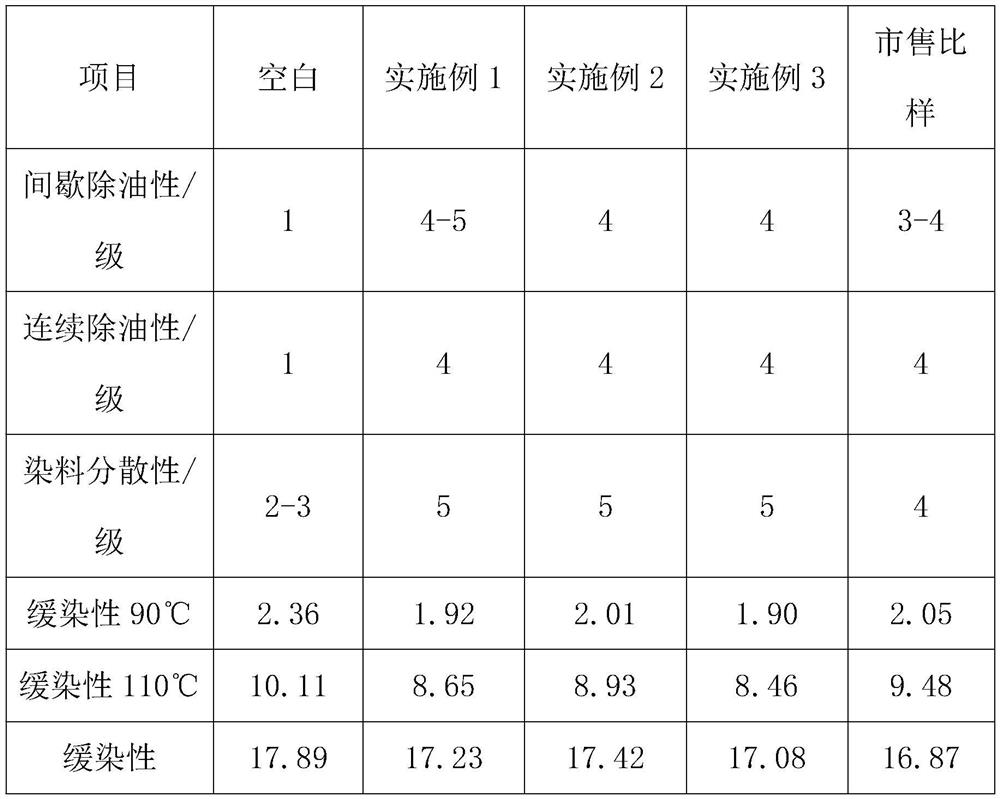

[0023] 1. Experimental method:

[0024] (1) Fabric:

[0025] Polyester woven fabric (75D, 96F), fabric to be dyed after bleaching.

[0026] (2) Application process:

[0027] Dyeing process prescription: dye 2% (o.w.f), auxiliary agent 0.5g / L, liquor ratio 1:15.

[0028] (3) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap