Technology for removing urease from whole soybeans

A soybean and urease technology, applied in the processing field, can solve the problems of low urease removal rate, influence on nutrient absorption, high activity, etc., and achieve the effects of improving appearance, reducing activity, and improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

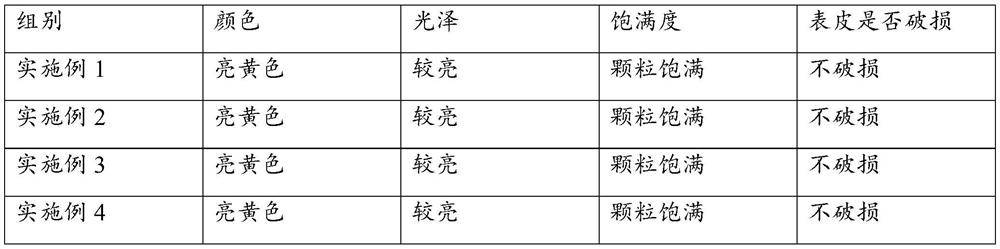

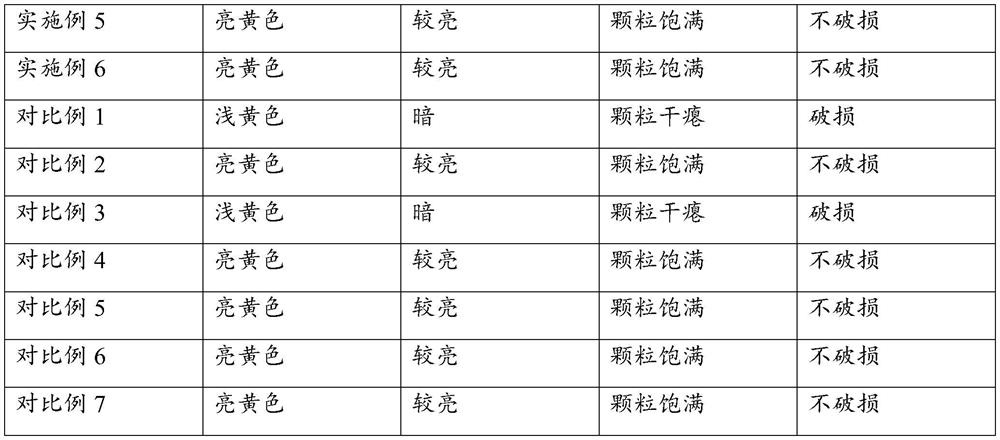

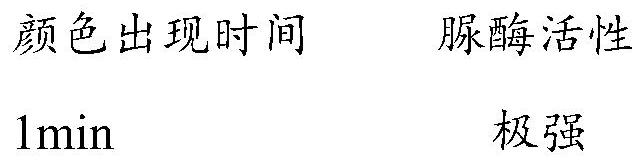

Examples

Embodiment 1

[0026] A process for removing urease from whole soybeans, comprising the following steps:

[0027] S1. Wash the soybeans, remove surface impurities, place them in a 3% ethanol solution with a mass concentration 4 times the weight of the soybeans and soak for 2 minutes, then add an additive compounded by Tween-80, isopropanol and lauryl alcohol to the ethanol solution , the mass ratio of the ethanol solution and the additive is 1:0.2, and the soybeans are then soaked for 20min;

[0028] S2. Soak the soybeans soaked in the above step S1 with clear water 8 times the weight of the soybeans for 20 minutes, wash once, and the temperature of the clear water is 40°C;

[0029] S3. The soybeans washed in the above step S2 are baked at 100° C. for 2 hours, cooled down to room temperature rapidly, and filled.

[0030] In this embodiment, the mass ratio of Tween-80, isopropanol and lauryl alcohol is 5:5:1.

Embodiment 2

[0032] A process for removing urease from whole soybeans, comprising the following steps:

[0033] S1. Wash the soybeans, remove surface impurities, place them in a 4% ethanol solution with a mass concentration 5 times the weight of the soybeans and soak them for 2.5 minutes, then add Tween-80, isopropanol and lauryl alcohol compounded in the ethanol solution Additive, the mass ratio of described ethanol solution and additive is 1:0.3, and soybean is soaked 20min then;

[0034] S2. Soak the soybeans soaked in the above step S1 with clear water 9 times the weight of the soybeans for 30 minutes, wash 3 times, and the temperature of the clear water is 45° C.;

[0035] S3. The soybeans cleaned in the above step S2 are baked at 100° C. for 2.5 hours, cooled down to room temperature rapidly, and filled.

[0036] In this embodiment, the mass ratio of Tween-80, isopropanol and lauryl alcohol is 3:3:1.

Embodiment 3

[0038] A process for removing urease from whole soybeans, comprising the following steps:

[0039] S1. Wash the soybeans, remove surface impurities, place them in a 5% ethanol solution with a mass concentration 5 times the weight of the soybeans and soak them for 1.5 min, then add Tween-80, isopropanol and lauryl alcohol compounded in the ethanol solution Additive, the mass ratio of described ethanol solution and additive is 1:0.4, and soybean is soaked 30min then;

[0040] S2. Soak the soybeans soaked in the above step S1 with clear water 10 times the weight of the soybeans for 40 minutes, wash twice, and the temperature of the clear water is 50°C;

[0041] S3. The soybeans cleaned in the above step S2 are baked at 115° C. for 3 hours, cooled down to room temperature rapidly, and filled.

[0042] In this embodiment, the mass ratio of Tween-80, isopropanol and lauryl alcohol is 4:3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com