Clean jaw crusher with discharging granularity being adjustable and adjusting method of clean jaw crusher

A jaw crusher and adjustable technology, applied in grain processing and other directions, can solve the problem of non-adjustable horizontal stroke of the discharge port, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

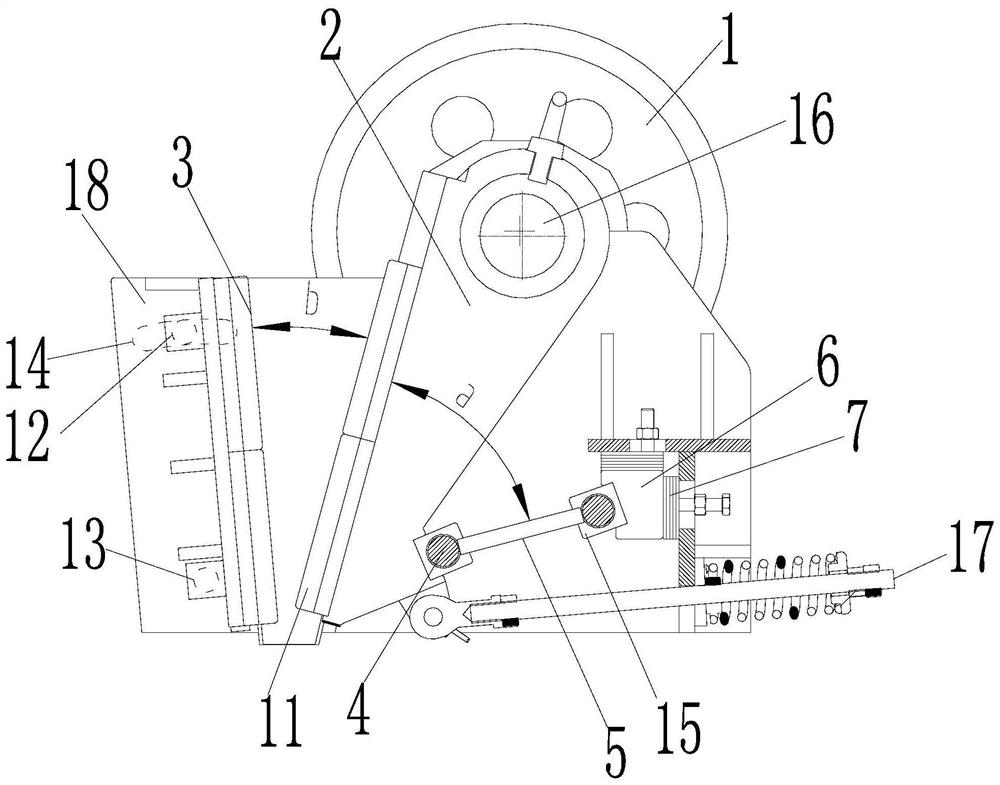

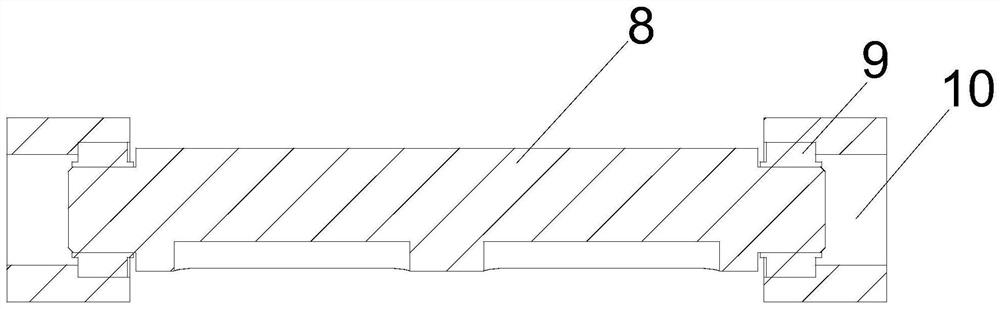

[0052] see figure 1 and figure 2 , this embodiment provides a clean jaw crusher with adjustable discharge particle size and its adjustment method. The jaw crusher includes a static jaw, a movable jaw, a movable jaw, a frame, a rotating shaft 1, and a 2. Adjusting seat, toggle plate, adjusting seat rotating device, pulley, toggle plate rotating device, eccentric shaft, driving mechanism, controller, power supply and spring pull rod.

[0053] The static jaw plate 3 is fixed on the frame of the jaw crusher, while the movable jaw plate 2 is installed obliquely. The movable jaw plate 11 is fixed on the movable jaw plate 2, and the static jaw plate 3 is separated from the movable jaw plate 11. And, the angle between the static jaw plate 3 and the movable jaw plate 11 is defined as the pincer angle. In this embodiment, the arrangement of the movable jaw 2, the static jaw 3 and the movable jaw 11 can be the setting of the jaw crusher in the prior art, and the static jaw 3 and the m...

Embodiment 2

[0067] This embodiment provides a particle size adjustment method, which is applied to the clean jaw crusher with adjustable discharge particle size in the above embodiment 1. Wherein, the particle size adjustment method includes the following steps.

[0068] First obtain an input and output particle size required by the outside, and then query an input tong angle angle corresponding to the input and output particle size in a preset pincer angle angle-output particle size comparison table, and then obtain the current jaw crusher. Clamp angle, and finally compare the input clamp angle with the current clamp angle;

[0069] When the current pincer angle is greater than the input pincer angle, the controller drives the other end of the static jaw plate 3 to swing in the direction of the movable jaw plate 11 with the rotating shaft 13 as the rotation axis through the drive mechanism; when the current pincer angle angle is smaller than the input pincer angle Angle, the controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com