An online control method and control system for the pressing process of a forging press

A technology of pressing process and control method, which is applied to the driving device of forging presses, etc., can solve problems such as uncontrollable system stability, and achieve the effect of ensuring system stability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

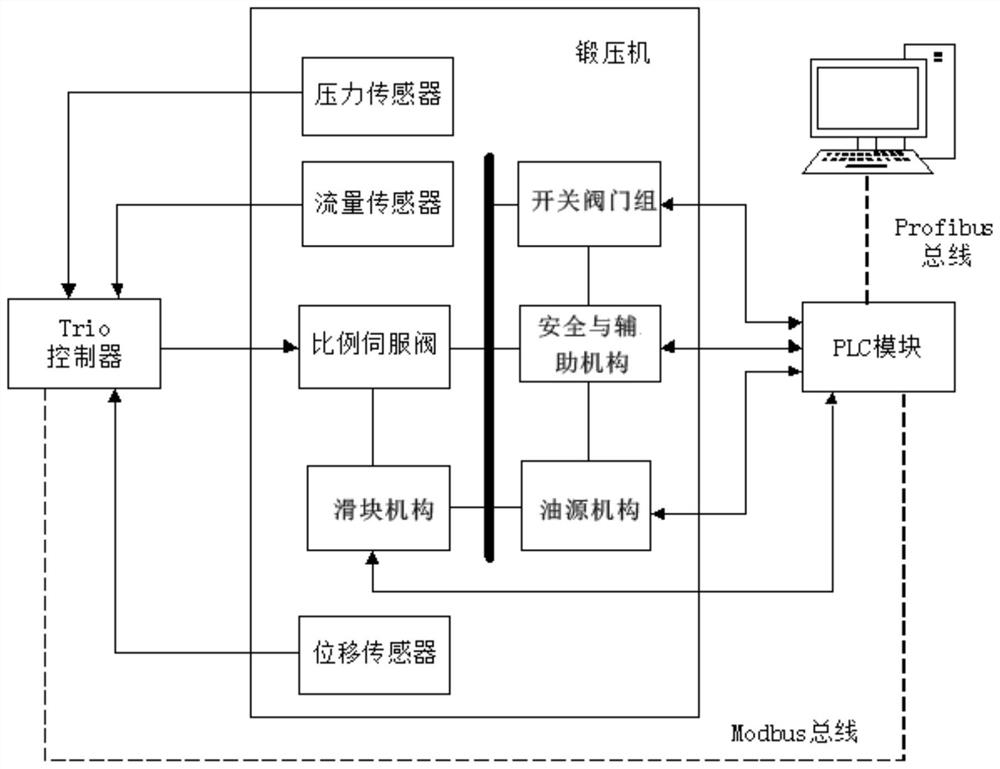

Method used

Image

Examples

Embodiment 1

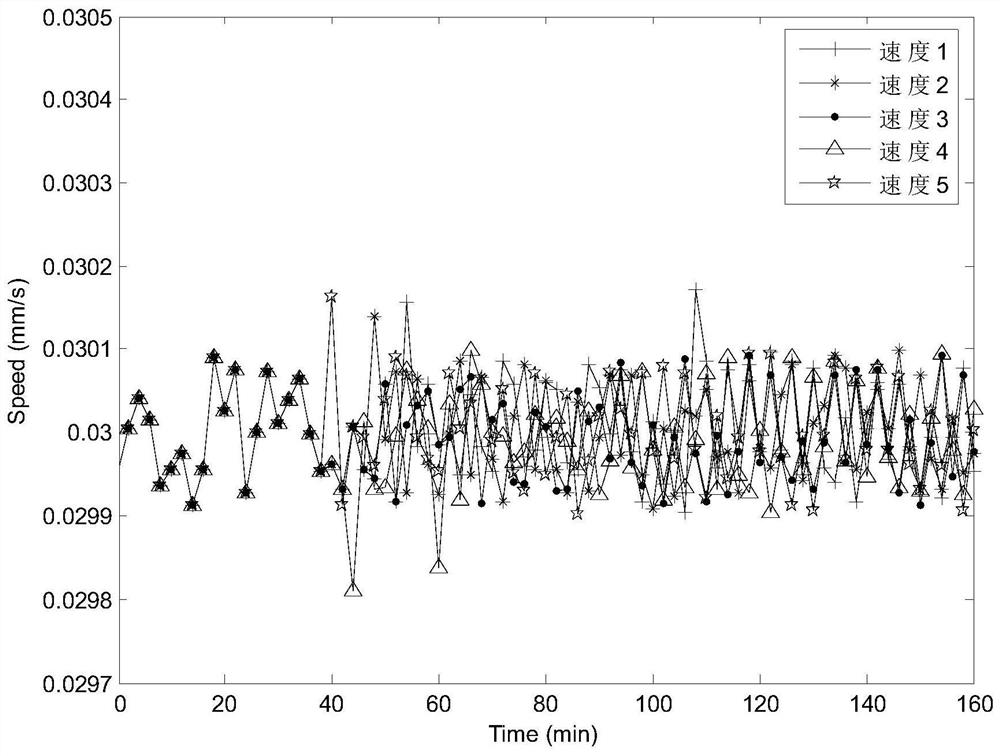

[0111] Example 1: Low constant speed state

[0112] The slider is set to 0.03mm / s, and since the pressure is very slow, the water consumption of the oil in the hydraulic cylinder is small, and the proportional servo valve has a large variable diameter loss pressure due to the small opening degree. Therefore, the opening degree of the proportional servo valve is a hydraulic cylinder working pressure and a circulation flowing through the servo valve pressure loss. Since the contraindication search is a random search, a certain random search is shown, this embodiment has tested 5 times for the lower pressure process. Figure 2A Is a speed diagram, Figure 2B It is a schematic diagram of the output of the controller, and the different colors represent each test.

[0113] From Figure 2B It can be seen that each curve is not fully covered, which reflects that each control value is not completely consistent with the method of the present invention. Figure 2A These control values are re...

Embodiment 2

[0115] Example 2: Variable Speed State

[0116] The speed is set to 0.08mm / s from the beginning, after 0.04mm / s, the final output 0.06mm / s, the process description, as shown in the formula (17)

[0117]

[0118] This embodiment repeats the application effect of 5 times to test the recommended method. Figure 3A It is a schematic diagram of the pressing process in the shift state; Figure 3b It is a schematic diagram of the output of the controller.

[0119] From Figure 3A It can be seen that each curve can track the speed of setting up in different speed changes, at 1-30 speed set value of 0.08, the maximum peak 0.0812 occurs in the 5th, minimum 0.0788; at 50 The speed set value of 0.04, the maximum peak 0.0406 occurs in the 3rd, minimum 0.0394, occurs in the first, 2, 3, 4 times; at 80-100 period speed setpoint is 0.06, the maximum peak value The minimum peak is 0.0609 and 0.0394, respectively, and the relative error is 1.5%. The mean and residuals of each time are shown ...

Embodiment 3

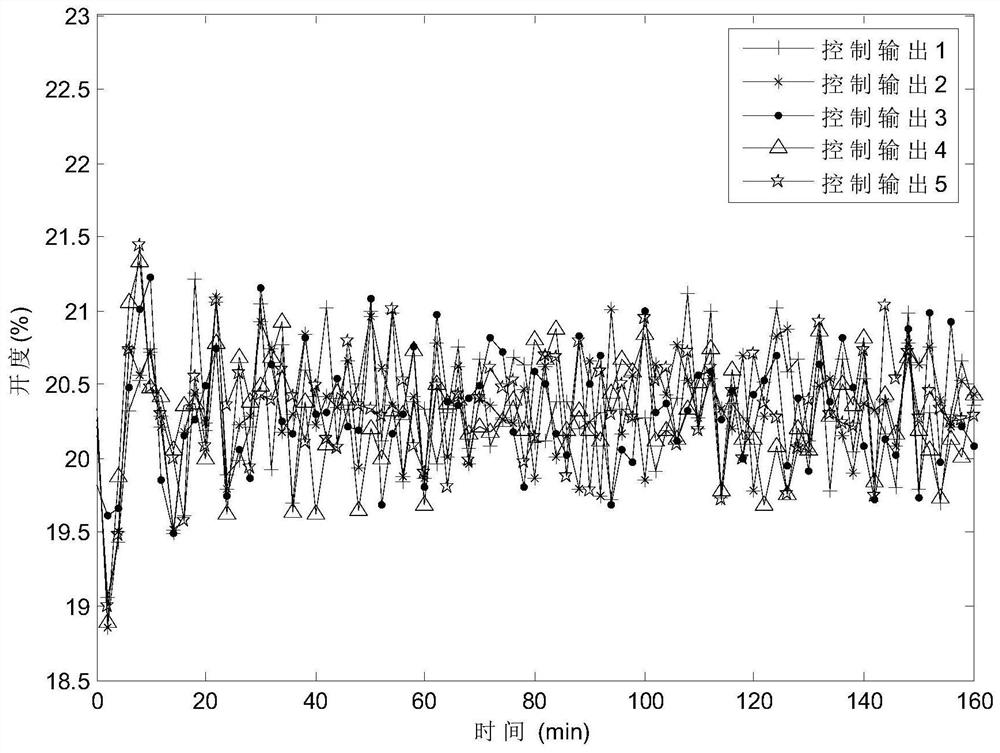

[0122] Example 3: Effect of sampling cycle

[0123] This embodiment tested the impact of the method recommended by the method of different sampling cycle. The sampling cycle is selected for 1-5 minutes, and the reference speed is selected from 0.04mm / s, the result is as Figure 4A and 4b Indicated. When the controller starts at the beginning, the automatic control is performed in the online control method according to the present invention. Figure 4A The curve in the middle represents the slider under different sampling cycles, Figure 4b Reflects the output of the controller under different sampling cycles. As can be seen from the figure, the different sampling cycles have a large influence, the sampling cycle is short, the duration of the transient process is short; the sampling cycle is long, the transition time is longer. The main reason is that the control amount obtained by the recommended method is constant in a sampling cycle. When the sampling period is short, it can adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com