Optimization control system for energy system of drying part of paper machine

A system optimization and control system technology, applied in the direction of paper machine, dryer department, paper making, etc., can solve the problems of untimely correction, unsatisfactory control effect, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

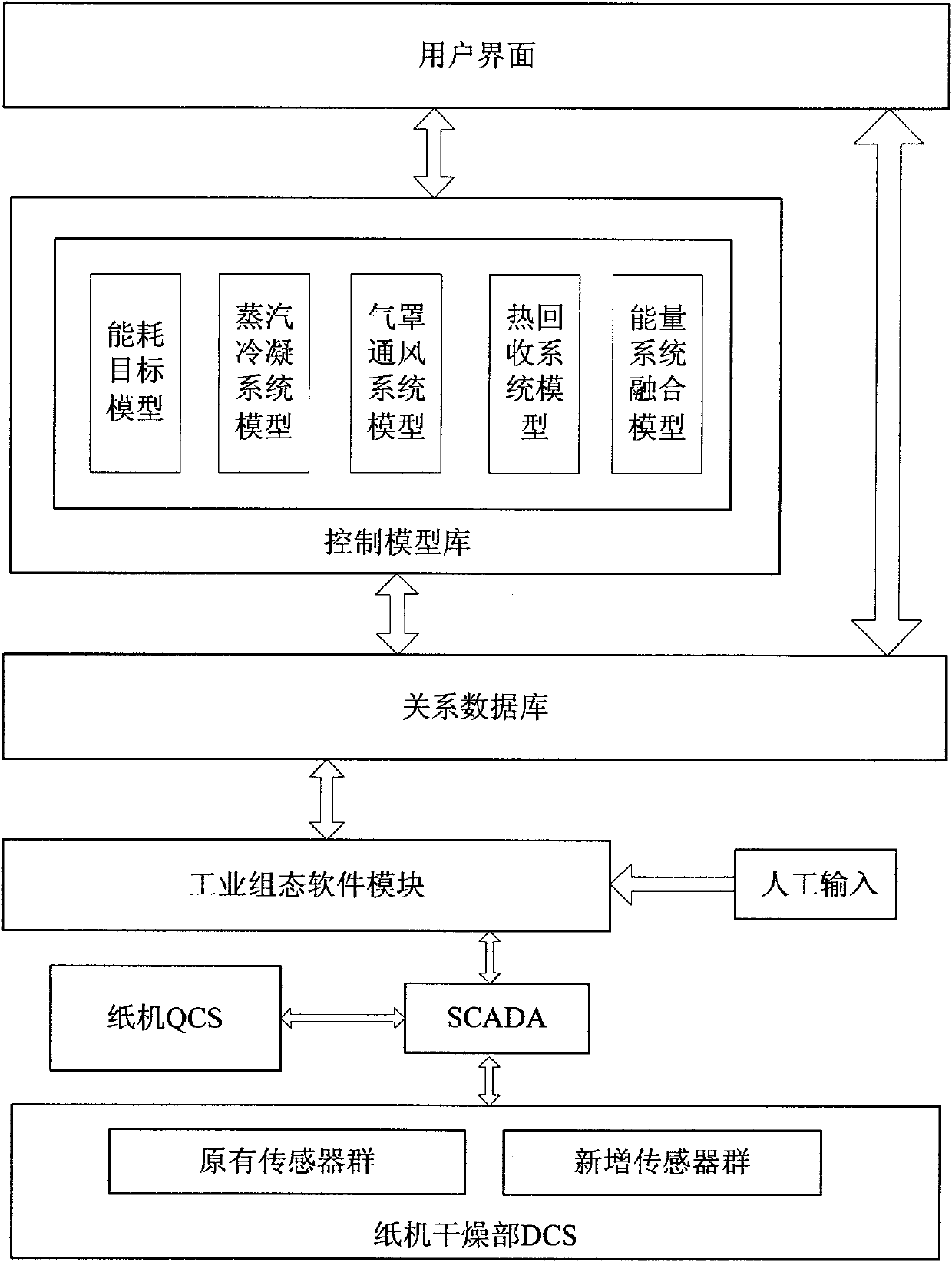

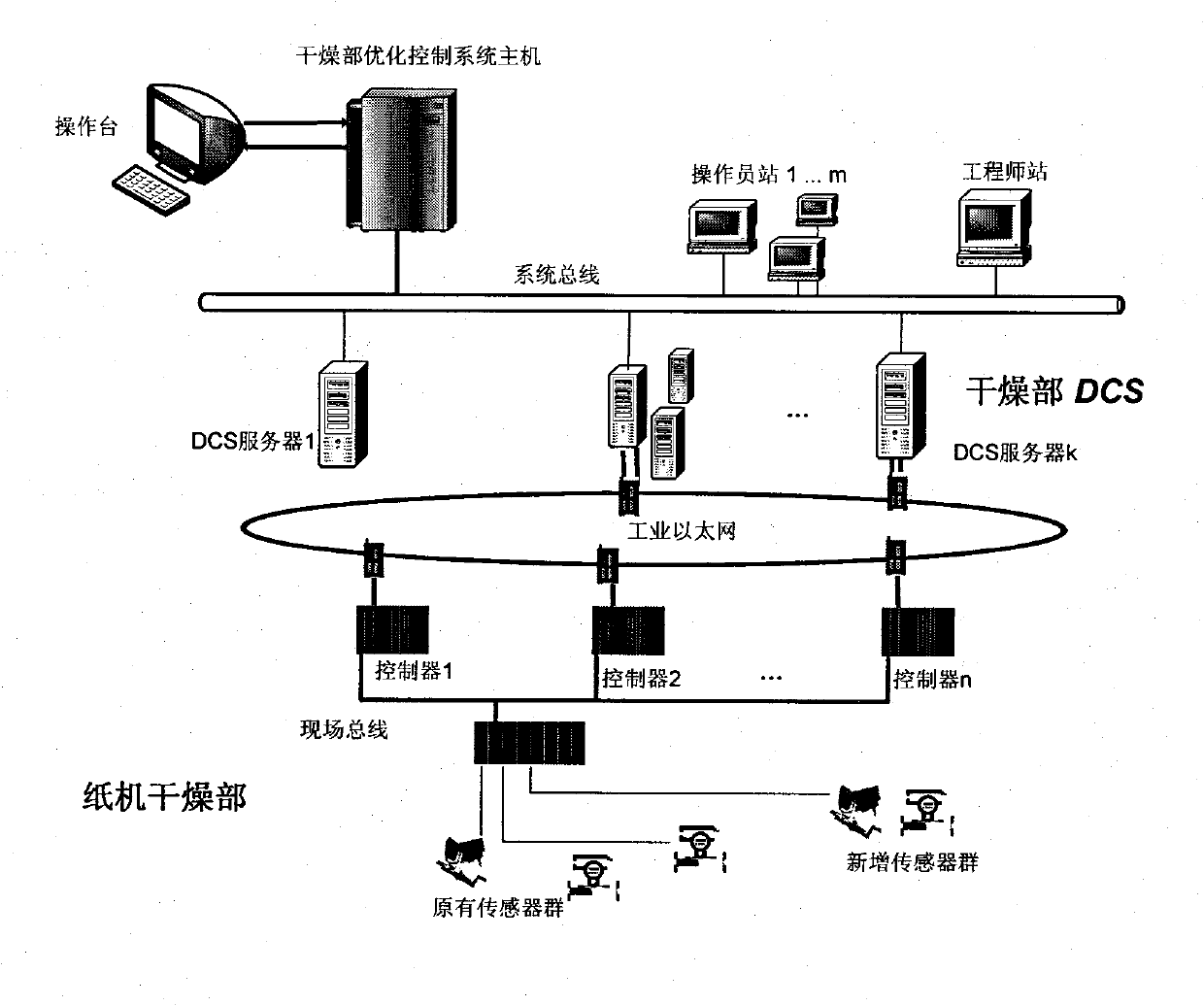

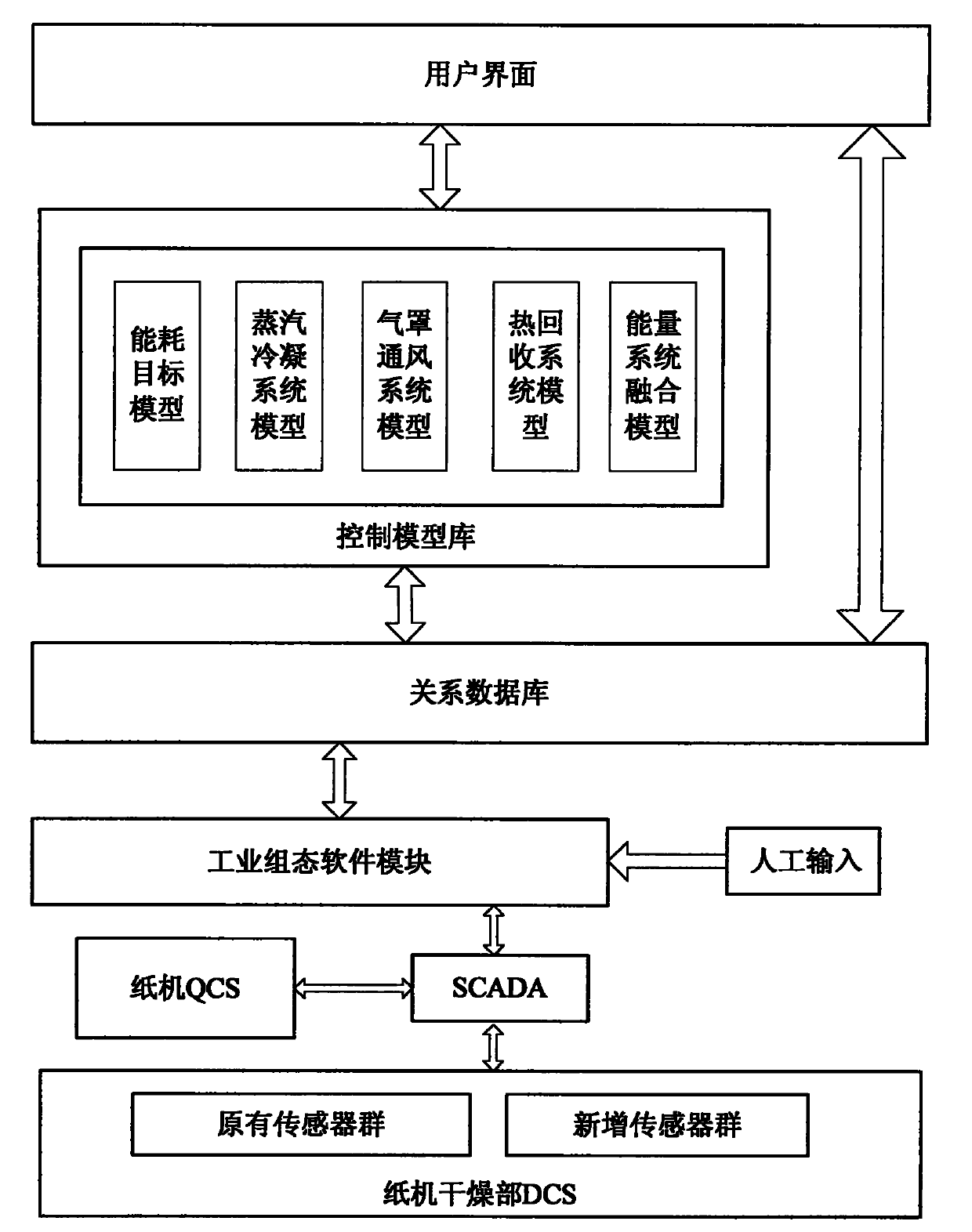

[0199] The principle block diagram of the present invention is as figure 1 As shown, it includes paper machine drying section DCS, paper machine QCS, SCADA, industrial configuration software modules, relational database, control model library and user interface. The newly added on-site sensor group is connected to the DCS of the drying section; the industrial configuration software module is connected to the DCS of the drying section, the paper machine QCS and the relational database; the relational database is connected to the control model library; the user interface is connected to the control model library and Relational databases are connected to each other.

[0200] The original on-site sensor group and the new on-site sensor group are integrated in the DCS of the drying section of the paper machine. The newly added sensor group includes: field sensors for temperature, humidity, dew point, pressure, wind speed and flow. It is used to measure the flow and pressure of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com