Hydraulic structure assembly of steering gear

A steering gear and hydraulic technology, which is applied to steering mechanisms, power steering mechanisms, fluid steering mechanisms, etc., can solve the problems of high steering noise, etc., and achieve the effects of reducing steering noise, convenient processing, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

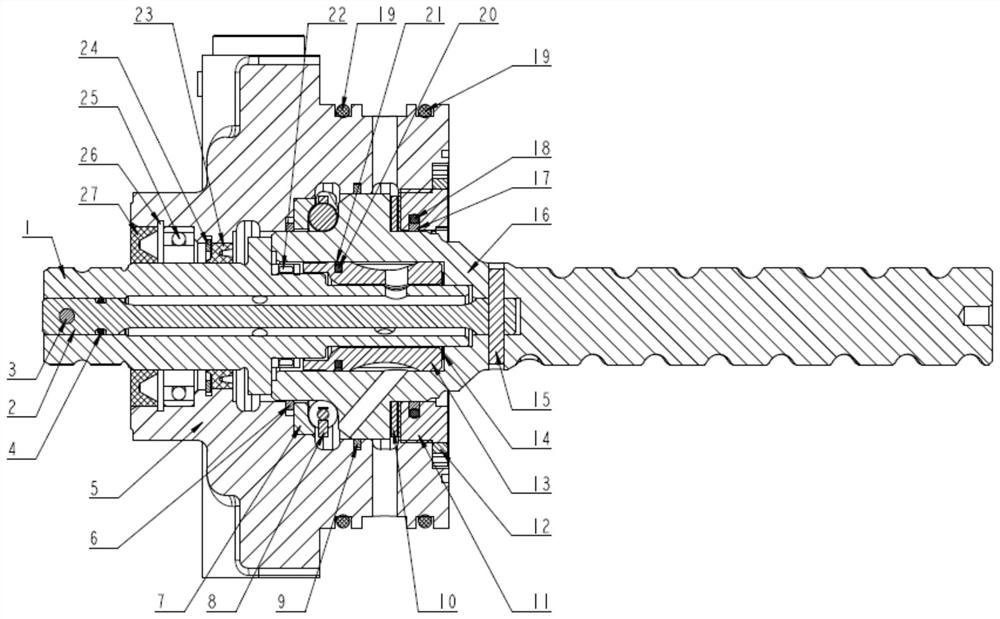

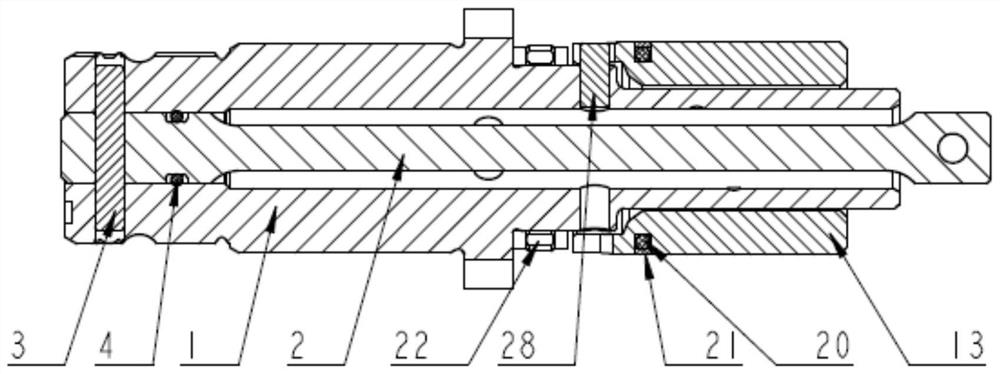

[0036] Such as figure 1 As shown, the present invention discloses a novel hydraulic structure assembly of a power steering gear, comprising an input shaft 1, a spool 13, a screw 16 and a torsion bar 2, the large end of the screw 16 has a valve sleeve inner hole, and the spool 13 is sleeved At one end of the input shaft 1, the spool 13 is connected to the input shaft 1 through a positioning pin 28, and one end of the input shaft 1 sleeved with the spool 13 is located in the inner hole of the valve sleeve; one end of the torsion bar 2 is connected to the input shaft through the first cylindrical pin 3 1 connection, and the other end is fixed with the screw rod 16 through the second cylindrical pin 15.

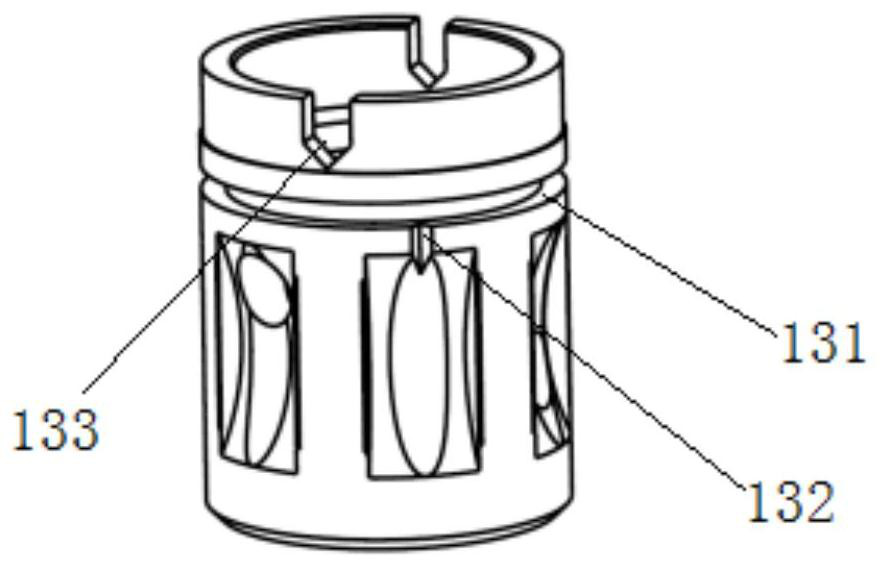

[0037] There is a positioning groove 133 at one end of the valve core 13, and a positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com