A cable laying device for electric power engineering construction and its application method

A technology of electric power engineering and cables, which is applied in the directions of cable laying equipment, transportation and packaging, and thin material handling, etc. It can solve problems such as the need for a period of transition time, the easy increase of belt loss, and the reduction of belt tension, so that the direction of transmission can be achieved. Controlling, reducing failures, not easy to be scattered and uneven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

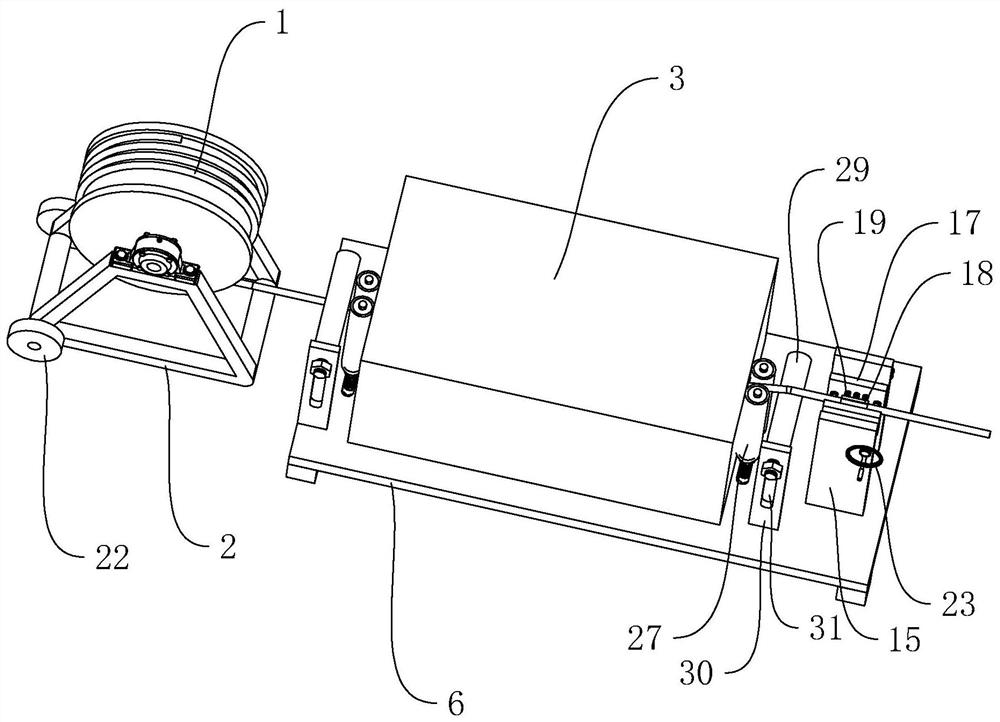

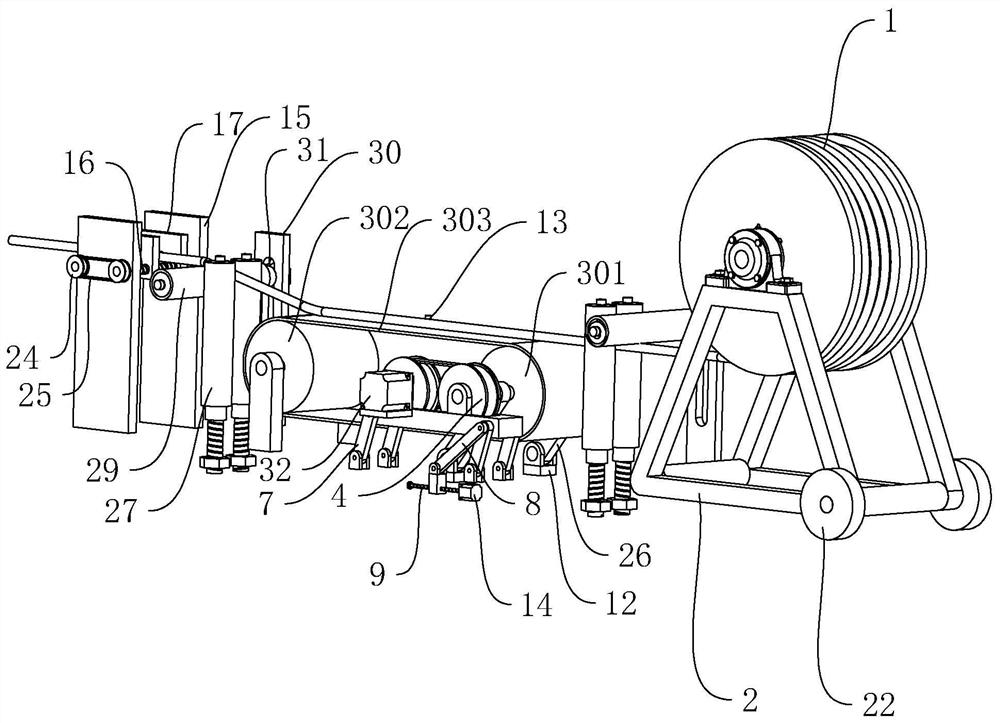

[0047] refer to figure 1 Embodiment 1 of the present invention provides a cable laying device for electric power engineering construction, including a wire frame 2 and a tractor 3, the cable 1 is wound on the wire frame 2 and laid along the length direction of the pipeline through the tractor 3 The bottom of the wire frame 2 is rotatably connected with a pulley 22 at one end, and there are two pulleys 22 arranged along a straight line. The bottom of the tractor 3 is fixed with a mounting base 6 .

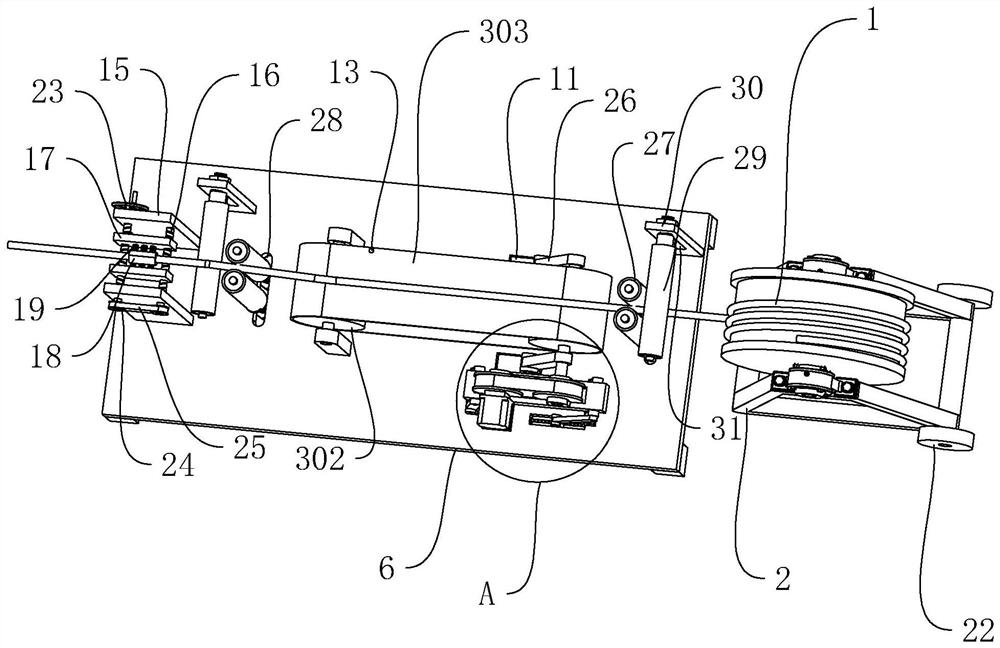

[0048] refer to figure 2 with Figure 5 The tractor 3 includes a driving wheel 301 and a driven wheel 302 which are rotatably arranged, and the driven wheel 302 is fixed on the upper surface of the mounting base 6, and the upper surface of the mounting base 6 is respectively provided with horizontally arranged chutes towards the two ends of the driven wheel 302 11, slide block 12 is all slidably connected in the chute 11 (see image 3 ), the two ends of the driving wheel 301 are...

Embodiment 2

[0064] Embodiment 2 of the present invention provides a method for using a cable laying device for power engineering construction, including a tension sensor 13 that monitors the tension of the belt 303 in real time, and reports to the microcontroller when the tension of the belt 303 is less than a preset value. Send a trigger signal;

[0065] The microcontroller receives the electrical signal of the tension sensor 13 and sends the starting electrical signal to the motor 14;

[0066] The motor 14 rotates and drives the screw rod 9 to rotate. The screw rod 9 drives the adjustment rod 8 to slide along the length direction of the screw rod 9. The adjustment rod 8 drives the retracting rod 7 hinged therewith to rotate, drives the adjustment seat 5 to move, and the adjustment seat 5 drives the gear 4 to move. 4 drive the driving wheel 301 to move, and change the distance between the driving wheel 301 and the driven wheel 302;

[0067] Until the tension value of the belt 303 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com