Steel reinforcement cage continuous manufacturing equipment and steel reinforcement cage manufacturing method

A technology for steel cages and equipment, which is applied to excavation, structural elements, building components, etc., can solve the problems of difficulty in construction coordination and communication of construction enterprises, difficult to control assembly and assembly accuracy, and reduced operation efficiency, so as to improve the efficiency of on-site assembly and avoid The effect of decentralization is difficult and the processing cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

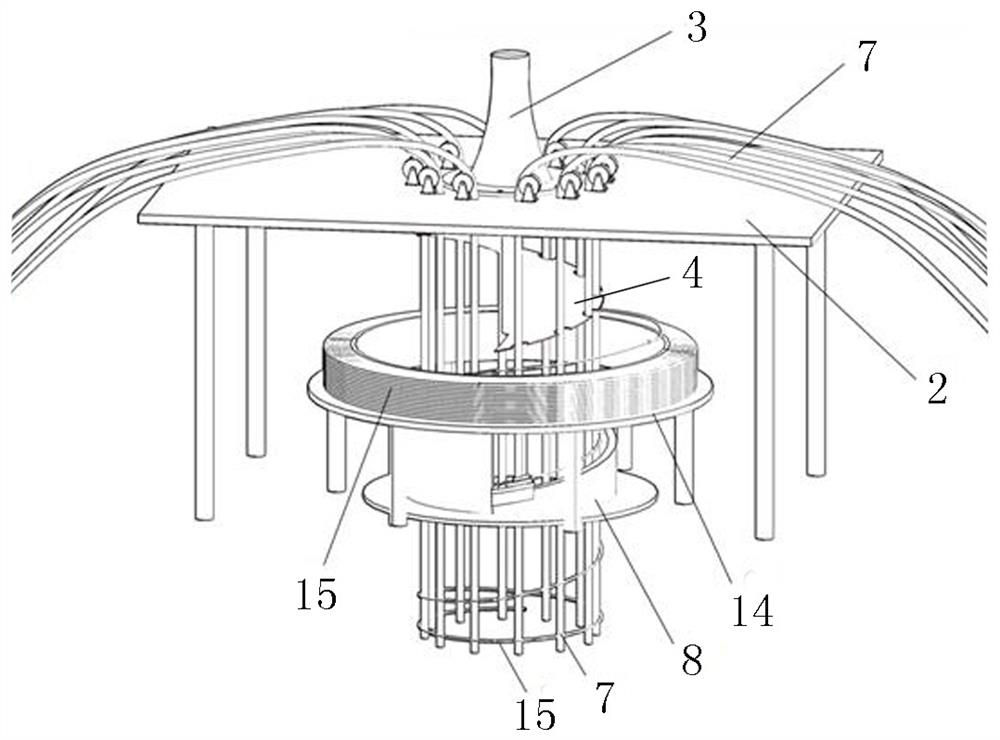

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

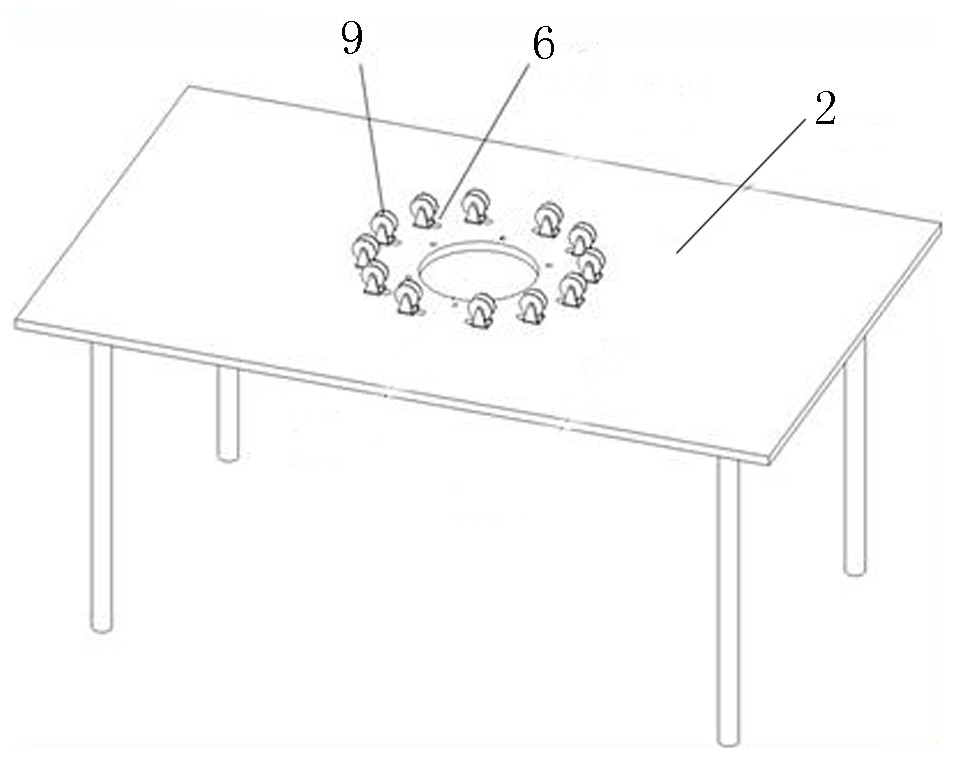

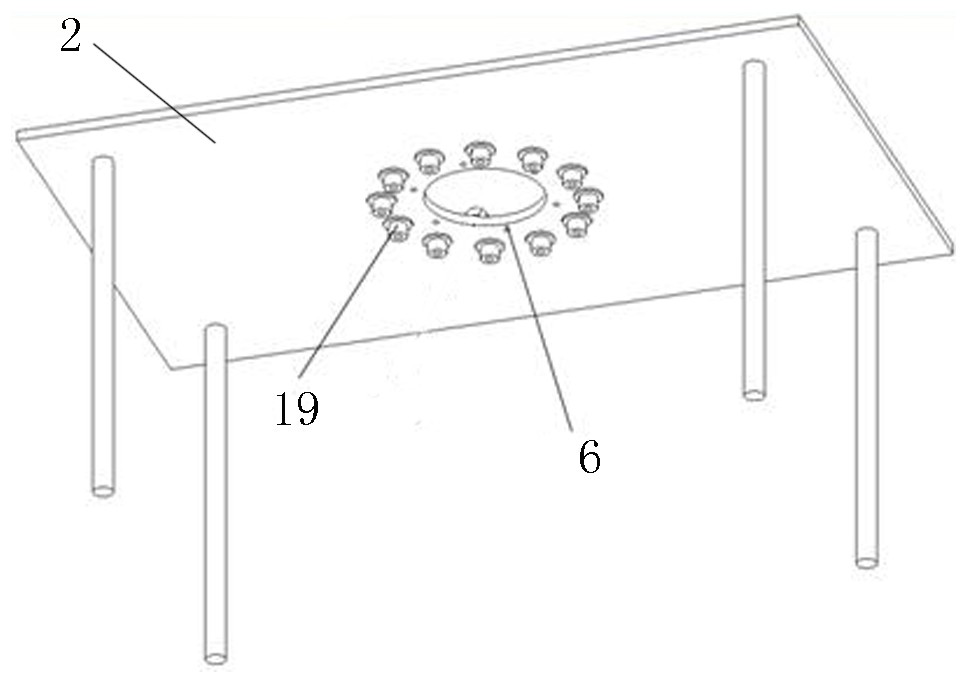

[0036] Such as Figure 1-8As shown, a kind of steel cage continuous production equipment is provided, including a forming enclosure structure slot 1, a reinforcement cage platform 2 is arranged above the forming enclosure structure slot, and a lowering cage is installed above the reinforcement cage platform. The propulsion device 3 is used for the lowering power source output of the steel cage; the front end of the lowering propulsion device is connected with a bearing plate 4, and a plurality of grooves 5 are evenly distributed on the bearing plate, and the number of grooves is the same as that of the steel cage The number of main bars is consistent; on the table of the steel cage stand, there are also a plurality of piercing holes 6 evenly distributed, and the main bars 7 of the steel cage are penetrated in the piercing holes, and the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com