Self-resetting connecting joint between steel frame and composite wallboard and fabricated building thereof

A technology of composite wall panels and connecting nodes, which is used in buildings, building components, building structures, etc., can solve problems such as high maintenance costs, impact on structural durability, and self-heavy weight, so as to improve the degree of integration and reduce structural losses. , the effect of reducing permanent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

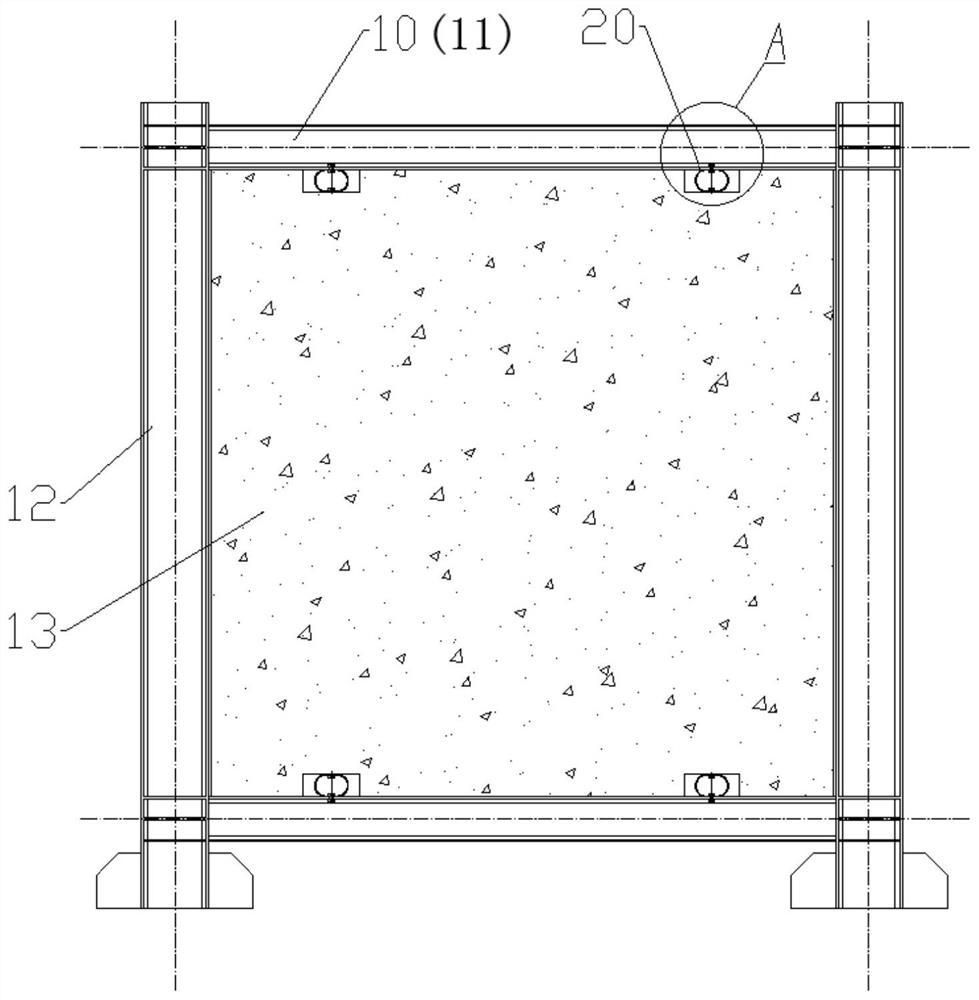

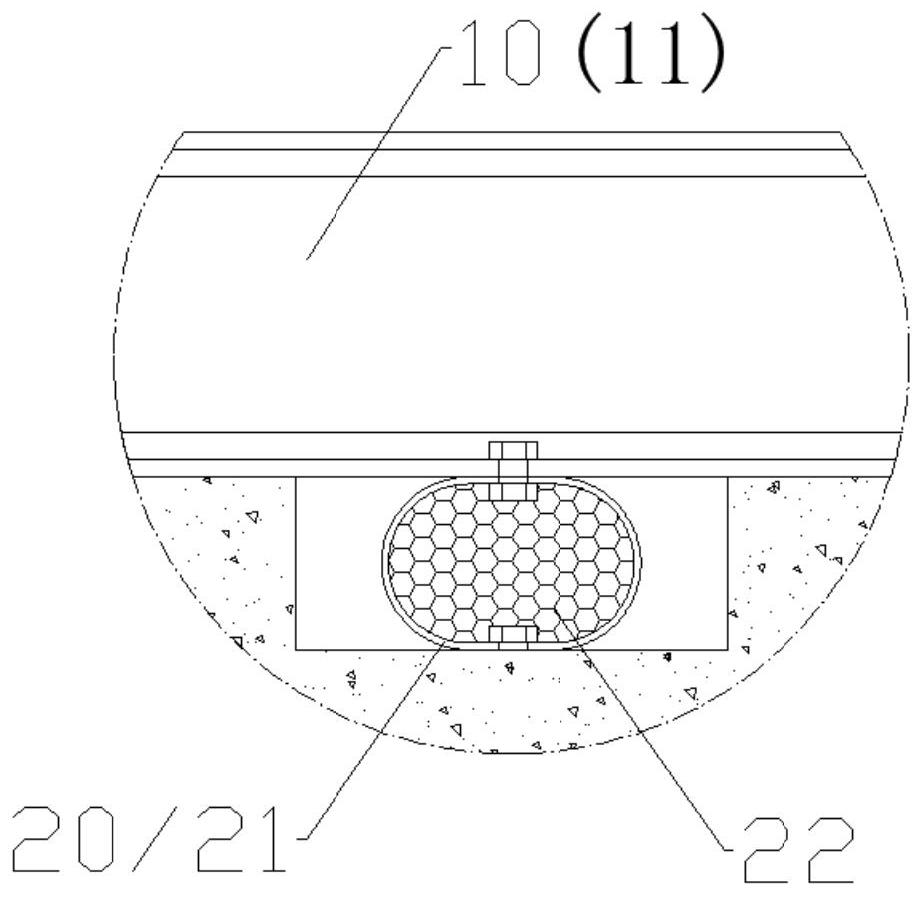

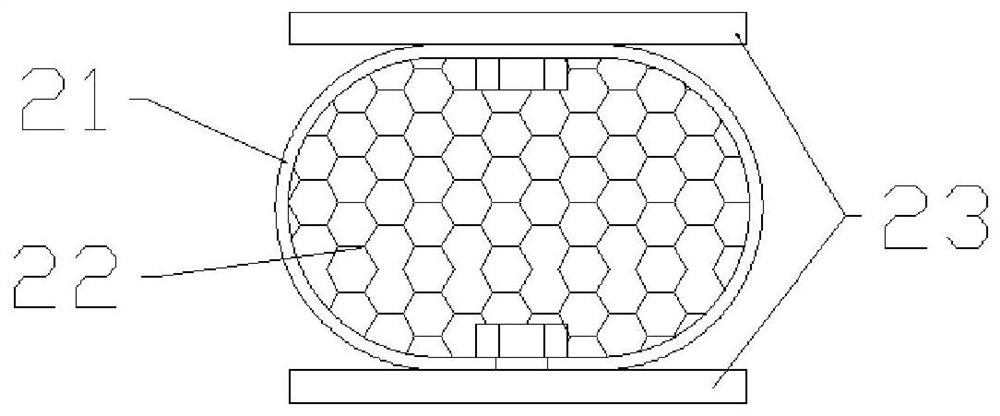

[0069] like Figure 1-2 As shown, this embodiment provides a self-resetting connection node between a steel frame and a composite wall panel, including: a frame 10 , a composite wall panel 13 and a self-resetting connector 20 ; the frame 10 includes a beam 11 and a column 12 . The composite wall panel 13 is arranged on the frame through a plurality of the self-resetting connectors 20; the self-resetting connectors 20 include a middle cylinder 21; Two straight line segments arranged in parallel, and two arc segments arranged symmetrically on both sides; the middle cylinder 21 is fixedly connected to the frame and the composite wall panel 13 through the two straight line segments, respectively. The intermediate cylinder 21 is filled with a heat insulating material 22 . The thermal insulation material 22 is preferably foamed aluminum. The self-reset connector 20 is made of a metal plate, and has a self-reset capability under the action of its own elasticity.

[0070] The struc...

Embodiment 2

[0075] refer to Figure 4 As shown, the present embodiment discloses a prefabricated building using the above-mentioned self-resetting steel frame composite wall panels to connect nodes, which includes: beams 11, columns 12, heat insulation boards 14 and cantilever beams 11a arranged outdoors; The connecting end of the cantilever beam 11a is provided with an end plate 16; the cantilever beam 11a is fixedly connected with the column body 12 through the end plate 16; the heat insulation plate 14 is arranged between the end plate 16 and the column body 12, and the heat insulation plate 14 is heated by the heat preservation plate 16. It is made of material for blocking heat conduction between the column 12 and the end plate 16 and the cantilever beam 11a.

[0076] In the present application, a thermal insulation board 14 is arranged between the cantilever beam 11a and the column body 12, and the thermal insulation board 14 is made of a thermal insulation material with low thermal ...

Embodiment 3

[0089] The structure of this embodiment is basically the same as that of Embodiment 2, and the difference is:

[0090] refer to Figure 12 As shown, this embodiment also includes a prefabricated cap 4a and a pile body 9, the prefabricated ground beam 1a is overlapped on the prefabricated cap 4a; the bottom of the prefabricated cap is connected with the pile body 9. The outside of the frame 10 is provided with cantilever beams 11a.

[0091] Preferably, the pile body 9 includes a concrete pile 101 and a steel pipe pile 100; on the horizontal projection plane, one or several steel pipe piles 100 are arranged between two adjacent concrete piles 101; The length of the pile is greater than the length of the steel pipe pile. The bottom of the concrete pile rests against a harder geological layer.

[0092] On the basis of the above scheme, more preferably, refer to Figure 13-16 As shown, the steel pipe pile 100 includes: a hollow steel pipe 110 and a rotatable stiffener assembly 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com