Spanning type molten salt pump supporting steel platform and molten salt pump supporting method

A molten salt pump and steel platform technology is applied in the field of structures supporting large-scale vertical long-axis rotary pumps, which can solve the problems of complicated construction, long cantilever distance, and high engineering cost, and achieve beautiful appearance, reduce engineering cost, and shorten construction. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

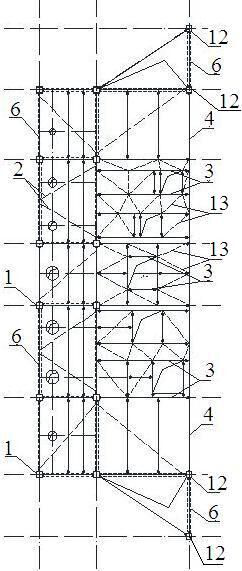

[0040] This embodiment provides a supporting steel platform for a spanning molten salt pump, including a three-dimensional frame, a spanning truss structure, an equipment platform layer, and an intermediate transition layer. The three-dimensional frame and the spanning truss structure are rigidly connected by beams, and the spanning truss structure Across the roof of the molten salt storage tank 7, the space between the three-dimensional frame and the spanning truss structure is the equipment platform layer, and the intermediate transition layer is arranged below the equipment platform layer;

[0041] The equipment platform layer includes a special-shaped support beam 3 and a horizontal support system. The special-shaped support beam 3 includes a transverse support beam and a longitudinal support beam. The transverse support beam is arranged between the three-dimensional frame and the spanning truss structure , the longitudinal support beam is arranged between the transverse su...

Embodiment 2

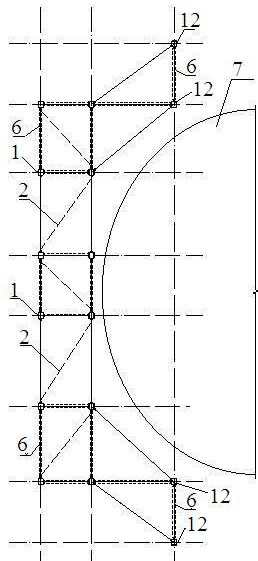

[0044]On the basis of Embodiment 1, this embodiment provides a spanning molten salt pump supporting steel platform, the three-dimensional frame includes longitudinal beams, beams and steel-concrete composite structural columns-1, and the spanning truss structure includes trusses Beam and steel-concrete composite structure column 2 12, the truss beam and steel-concrete composite structure column 2 12 are rigidly connected; the truss beam includes an upper chord steel beam, a lower chord steel beam 4 and a web 5, and the web 5 is arranged on the upper chord steel Between the beam and the lower chord steel beam 4, the lower chord steel beam 4 is rigidly connected to the transverse support beam.

[0045] The steel-concrete composite structure column 1 and the steel-concrete composite structure column 2 12 ensure the vertical and horizontal rigidity and bearing capacity of the overall support structure, and transmit all internal forces to the foundation.

Embodiment 3

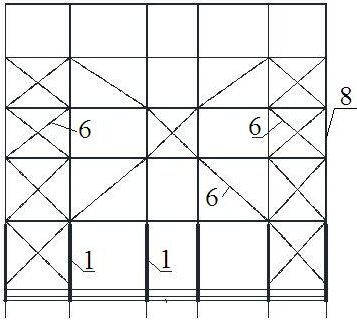

[0047] On the basis of Embodiment 1, this embodiment provides a spanning molten salt pump supporting steel platform, the horizontal support system includes a horizontal support member 1 and a horizontal support member 2 13, and the horizontal support member 1 is set Between the beams of the three-dimensional frame, the second horizontal support member 13 is arranged between the special-shaped support beams 3 , and the arrangement density of the second horizontal support member 13 is higher than that of the first horizontal support member 2 .

[0048] Such as figure 1 As shown, the horizontal supporting member 13 arranged on the equipment platform layer adopts the "encrypted small triangle" arrangement, and the horizontal supporting member 1 2 arranged on the three-dimensional frame adopts the principle of "diagonally spanning a large triangle". The torsional rigidity in the plane of the platform can be obviously improved, and the utility model has the advantages of strong inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com