Novel fastener production cooling device

A technology for cooling devices and fasteners, which is applied to household refrigeration devices, cleaning methods using tools, lighting and heating equipment, etc., and can solve the problems of lack of cold air circulation cooling, single cooling method of fasteners, and lack of temperature detection, etc. problem, to achieve the effect of increasing the cooling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

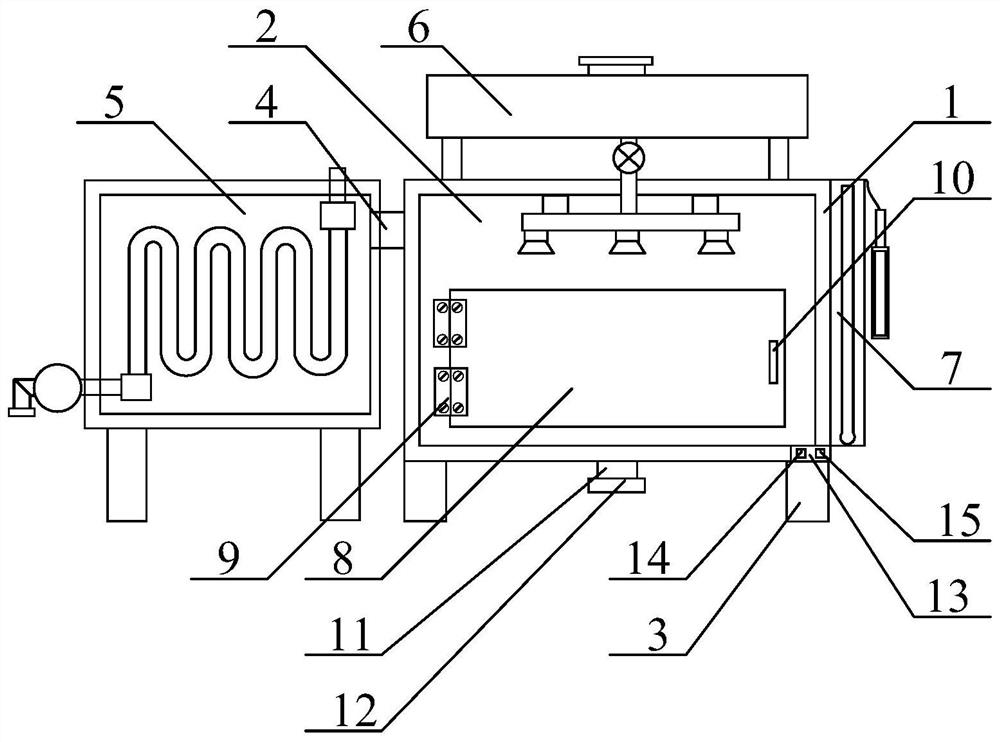

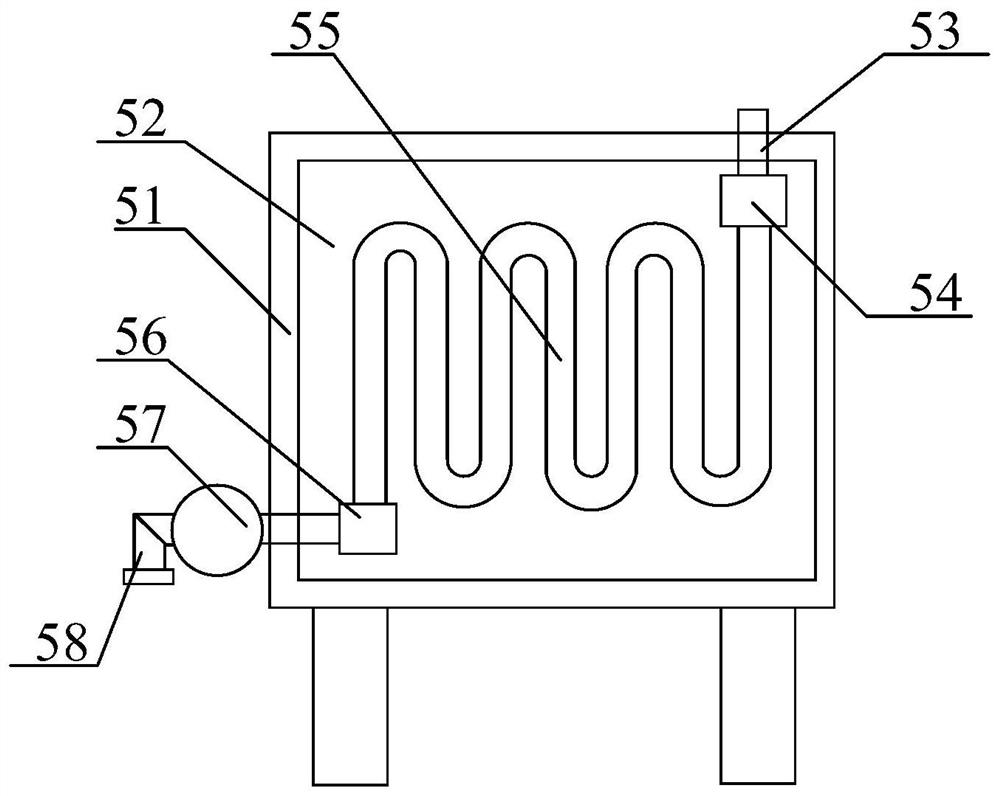

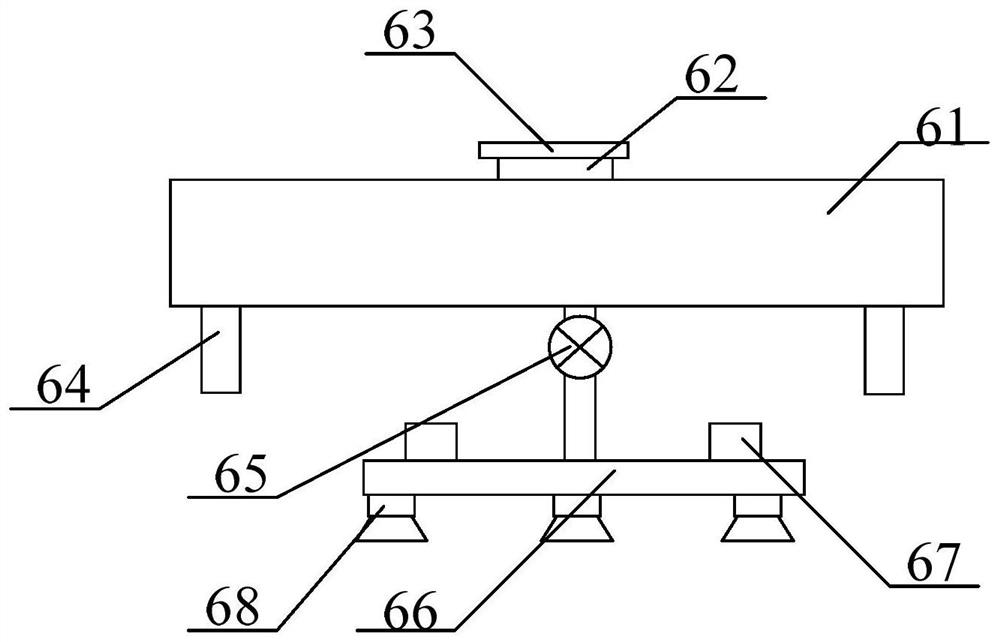

[0036] as attached figure 1 And attached figure 2As shown, a novel cooling device for fastener production according to the present invention includes a protective shell 1, a cooling box 2, a support seat 3, a conduit 4, a cold air circulation cooling frame structure 5, and a water storage fastener cooling frame structure 6. Fastener cooling temperature detection plate structure 7, protective door 8, hinge 9, handle 10, drain pipe 11, drain valve 12, connecting piece 13, cooling control switch 14 and suction control switch 15, the cooling The box 2 is bolted to the middle position inside the protective shell 1; the support bases 3 are respectively bolted to the four corners of the bottom of the protective shell 1; The cold air circulation cooling frame structure 5 is arranged on the left side of the conduit 4; the water storage fastener cooling frame structure 6 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com