Drainage asphalt mixture gradation design method based on virtual test

A technology for drainage asphalt and virtual testing, which is applied in design optimization/simulation, special data processing applications, geometric CAD, etc. It can solve the problem of inability to observe the structure of the skeleton, and achieve the effect of saving manpower, material resources and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

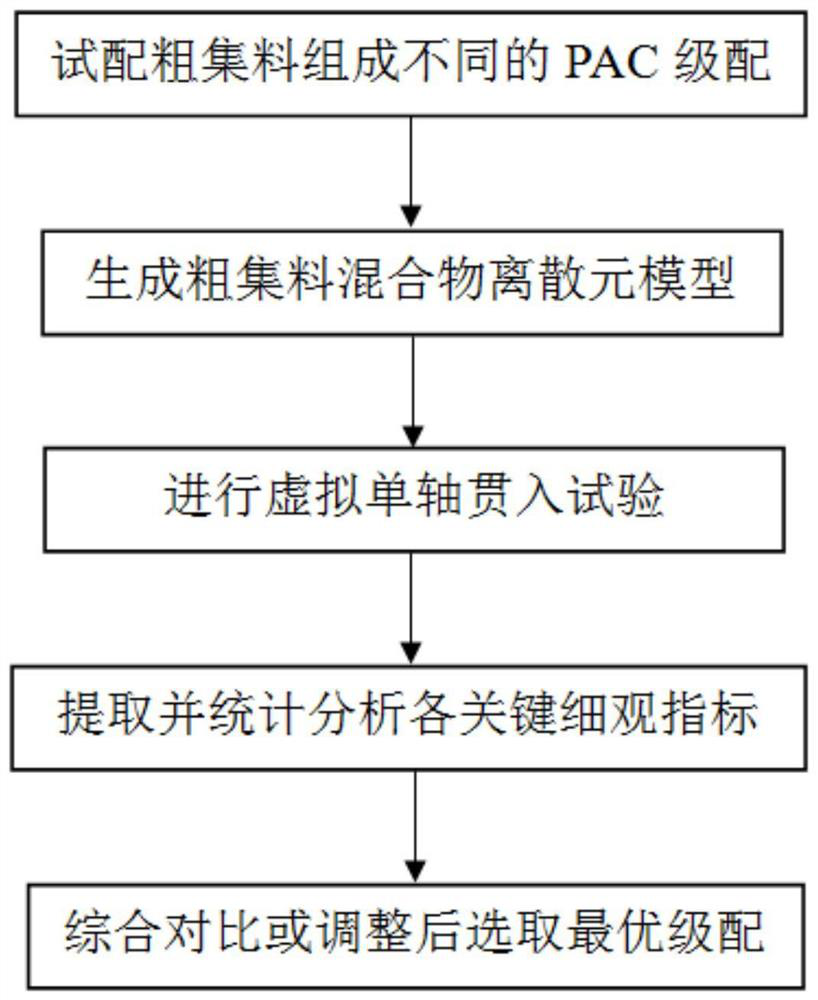

[0023] Such as figure 1 As shown, the optimal design method of drainage asphalt mixture based on the composition mechanism of this embodiment includes the following steps:

[0024] (1) According to the aggregate raw materials, three groups of coarse aggregates are tested to form different PAC gradations: under the condition that the content of coarse aggregate remains unchanged, that is, the pass rate of 2.36mm sieve remains unchanged, adjust the aggregates of each grade of coarse aggregate relative content between them.

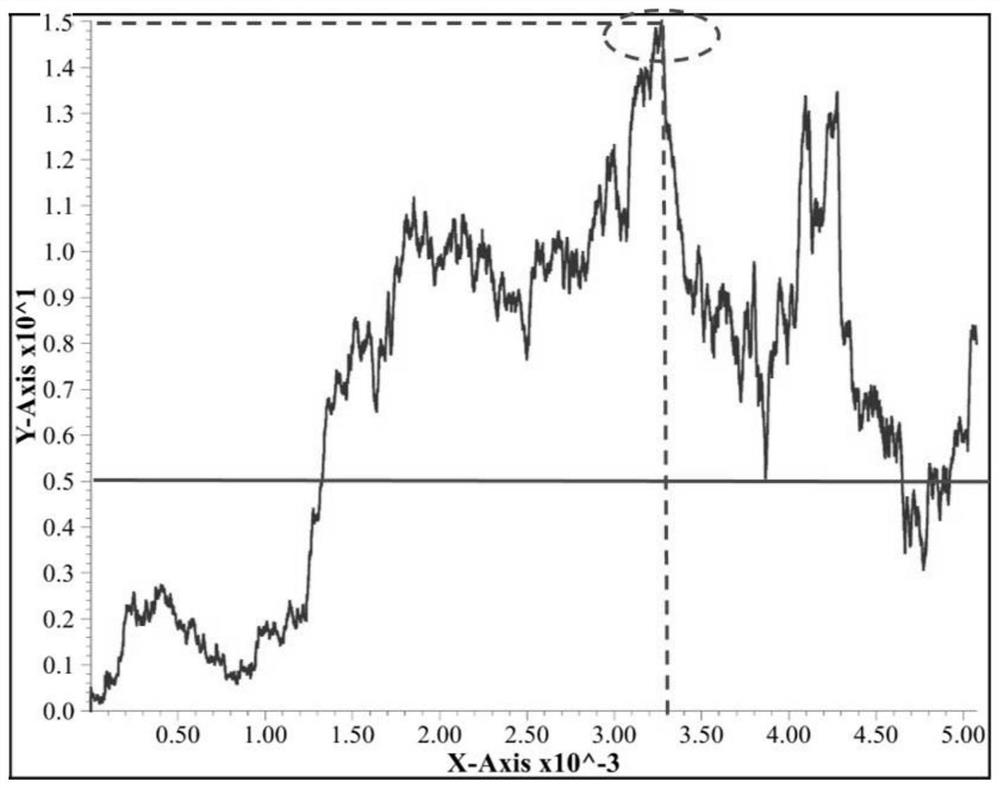

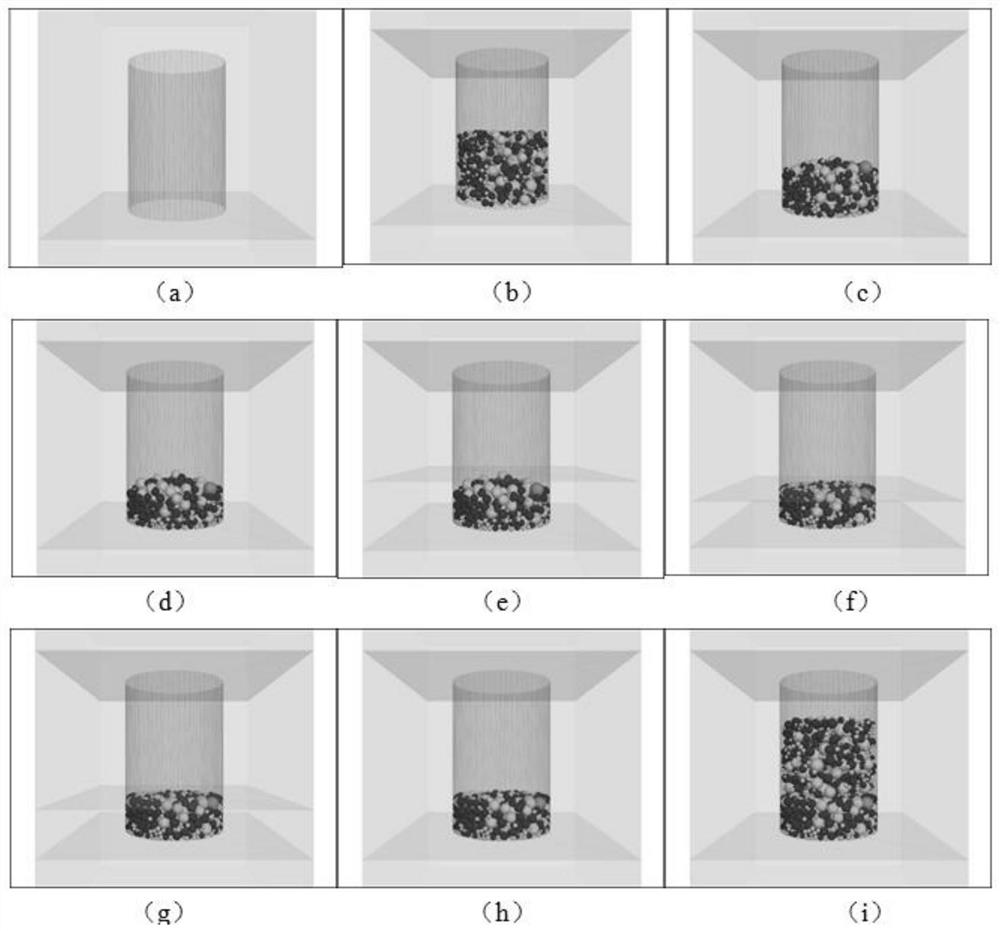

[0025] (2) Generate a discrete element model of a coarse aggregate mixture with a particle size of 2.36mm or more according to the trial distribution and gradation: calculate the number of aggregate particles of each grade to be generated; generate a virtual mold; in order to ensure the compaction quality, generate in three batches Aggregate granules, first generate the first aggregate granules; apply gravity and vibration to the first aggregate granules; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com