High-power TE-TEM microwave mode converter

A technology of TE-TEM and mode converter, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the problems of insufficient power capacity and difficulty in manufacturing, etc., to achieve improved power capacity, good conductivity, not easy to break or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

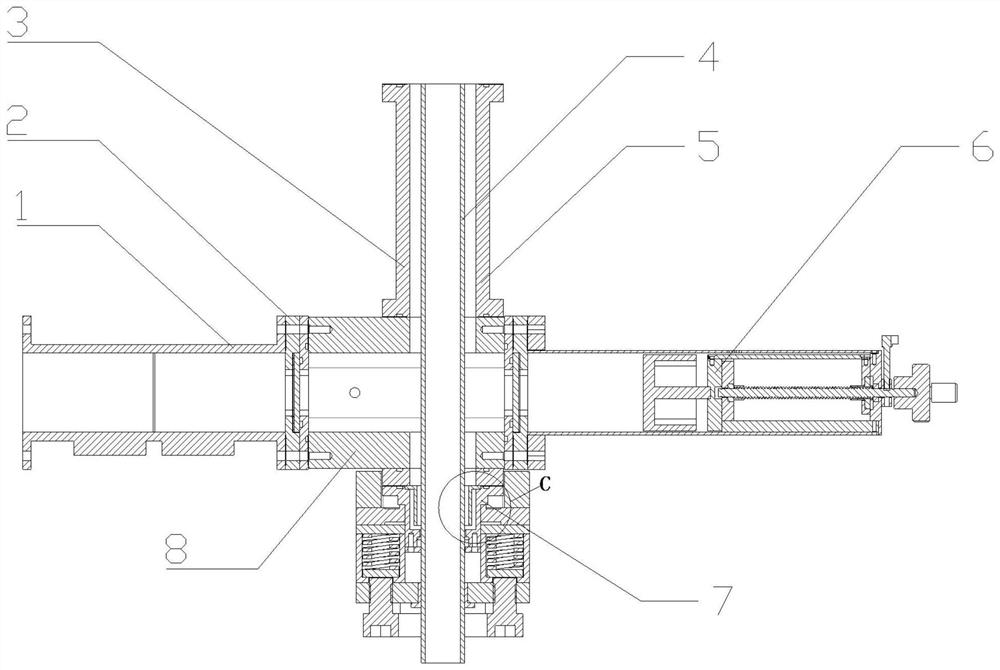

[0035] Such as figure 1 with 9 As shown, a high-power TE-TEM microwave mode converter includes a central waveguide 8, the left end of the central waveguide 8 is connected with a microwave feeding waveguide 1, the right end is connected with a microwave sliding circuit breaker 6, and the upper end is connected with a coaxial output 3, The lower end is connected with a coaxial short-circuit surface 7, and the coaxial output 3 is provided with a coaxial inner conductor 4 passing through the central waveguide 8 and the coaxial short-circuit surface 7 in sequence, and the coaxial short-circuit surface 7 includes a A centering ring 71, a short-circuit out-of-plane conductor 73 is installed on the centering ring 71, a coaxial down extension 74 is installed between the short-circuit out-of-plane conductor 73 and the center waveguide 8, and a coaxial down-extension section 74 and the short-circuit out-of-plane conductor 73 A microwave choke coil 72 which is not in contact with the coa...

Embodiment 2

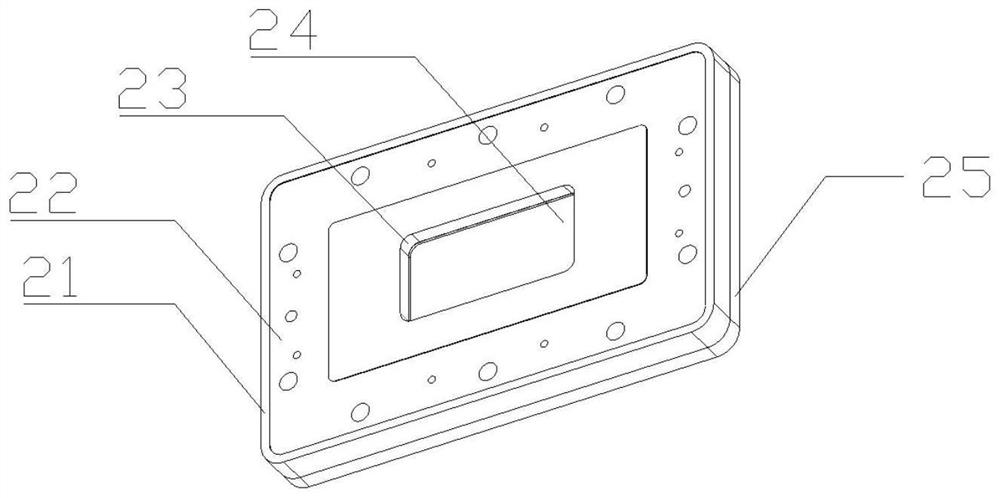

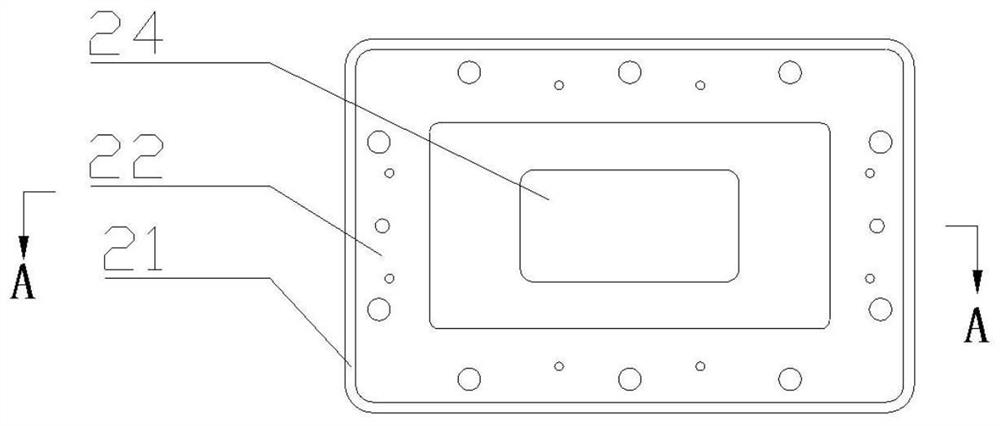

[0042] Such as Figure 2-5 As shown, on the basis of the above-mentioned embodiment 1, this embodiment provides the specific structure of the sealing window 2 and the microwave sliding circuit breaker 6, that is, the sealing window 2 includes an upper flange 21 and a lower flange 25 connected to each other, and the upper flange 21 and the lower flange 25 are connected to each other. The middle part of the flange 21 and the lower flange 25 has a window 27, and the bottom surface of the upper flange 21 has a mounting groove 29, and the gasket 26 and the quartz glass plate 24 in contact with each other are installed in the mounting groove 29 in sequence from top to bottom. , the quartz glass sheet 24 can close the window 27, and there is also a sealing groove 28 between the lower flange 25 and the quartz glass sheet 24, a sealing ring is installed in the sealing groove 28, the top surface of the upper flange 21 and the bottom surface of the lower flange 25 Both are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com