Pretreatment equipment for stir-fried melon seeds

A technology for pre-processing and frying melon seeds, which is applied in the direction of controlling mechanical energy, electrical components, and electromechanical devices. Accuracy and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

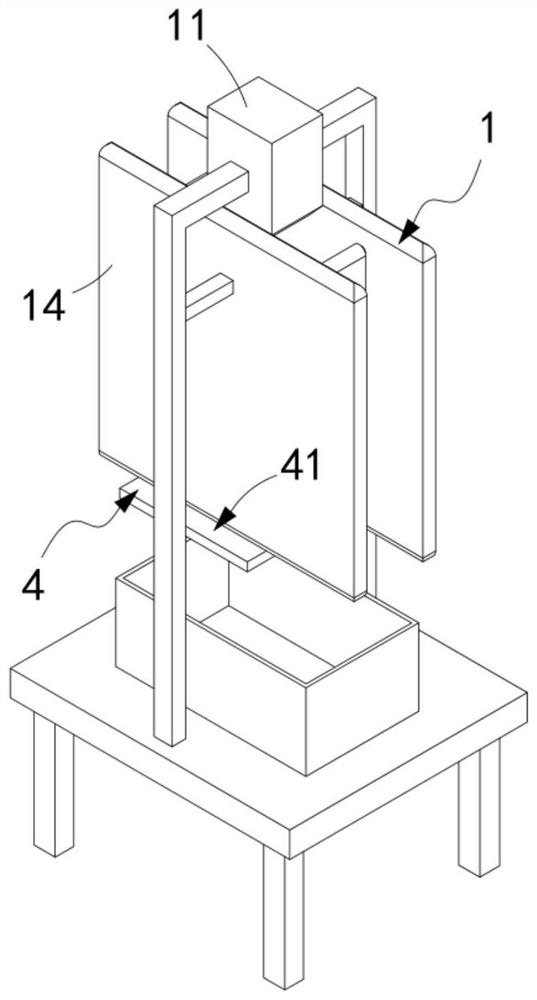

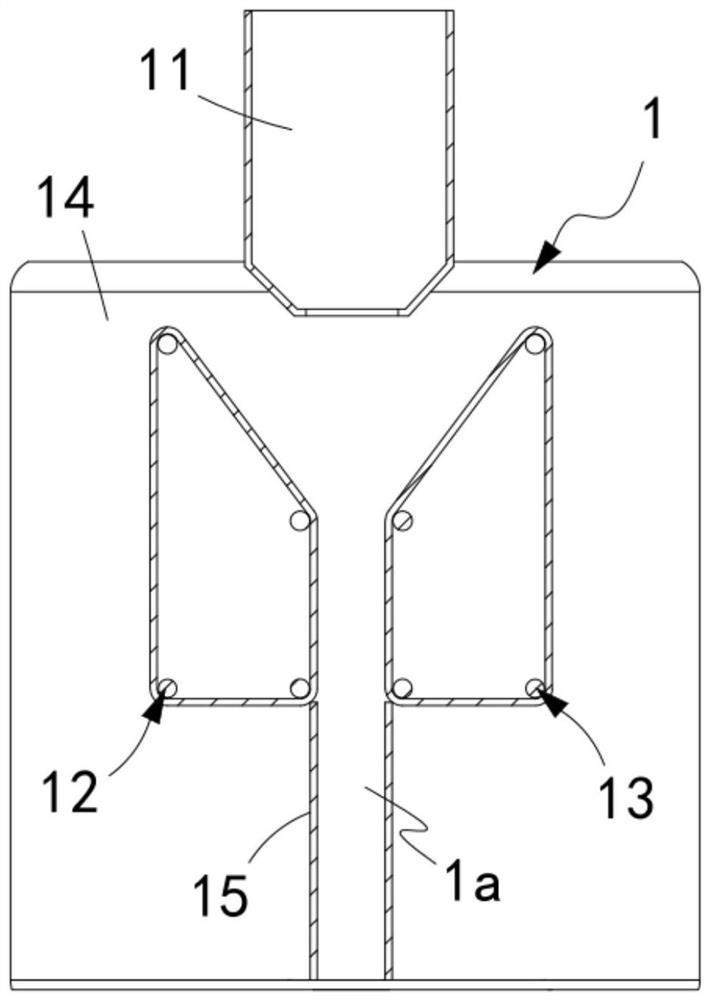

[0058] Such as figure 1 Shown, a kind of fried melon seeds pretreatment equipment comprises:

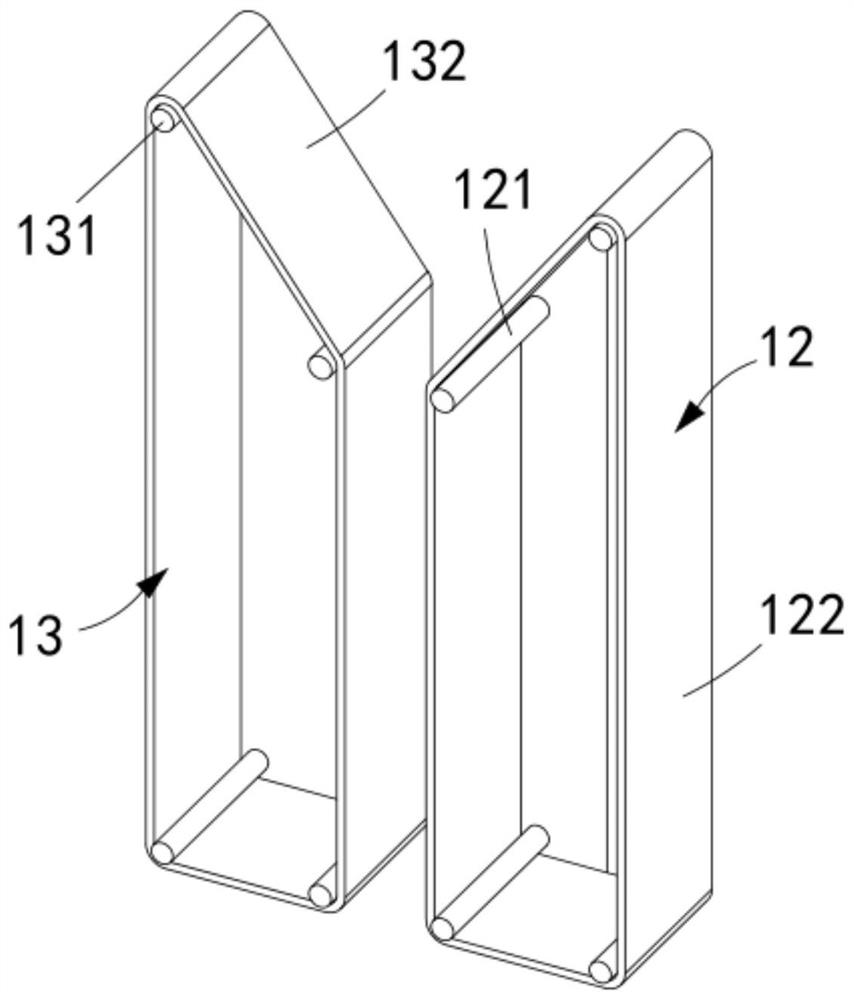

[0059] A sorting mechanism 1, the sorting mechanism 1 includes a discharge bin 11, a first dial assembly 12 arranged on one side of the discharge bin 11, and a first dial assembly 12 arranged on the discharge bin relative to the first dial assembly 12 11 The second dial assembly 13 on the other side, the melon seeds 100 bonded together are stored in the discharge bin 11, and the two sides of the first dial assembly 12 and the second dial assembly 13 are symmetrically arranged Two sets of partitions 14;

[0060] The separation mechanism 2, the separation mechanism 2 includes a support rod 21, several groups of insertion assemblies 22 arranged at equal intervals along the length direction of the support rod 21, and a floating assembly for connecting two adjacent insertion assemblies 22 twenty three;

[0061] The opening mechanism 3, the opening mechanism 3 is provided in several gro...

Embodiment 2

[0094] Such as Figure 8 to Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0095] further, such as Figure 8 to Figure 10 As shown, the insertion assembly 22 includes an insertion rod 221. The output end of the insertion rod 221 is arranged in a triangular structure and the pointed end is set toward the gap between two adjacent melon seeds. The unit 222 is slidably disposed in the sliding groove 223 of the support rod 21 .

[0096] In this embodiment, the output end of the insertion rod 221 is set in a triangular structure, which is beneficial for effectively inserting into the gap between two adjacent melon seeds, and the melon shell of the melon seeds is used to guide the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com