Automatic hook nail machining and forming equipment and machining method thereof

A technology of automatic processing and forming equipment, applied in mechanical equipment, nails, connecting components, etc., can solve the problems of quality problems of hook nails, complex hook nail processing procedures, low production efficiency, etc., so as to improve production and processing efficiency and process. Simple and effective in reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below through specific embodiments.

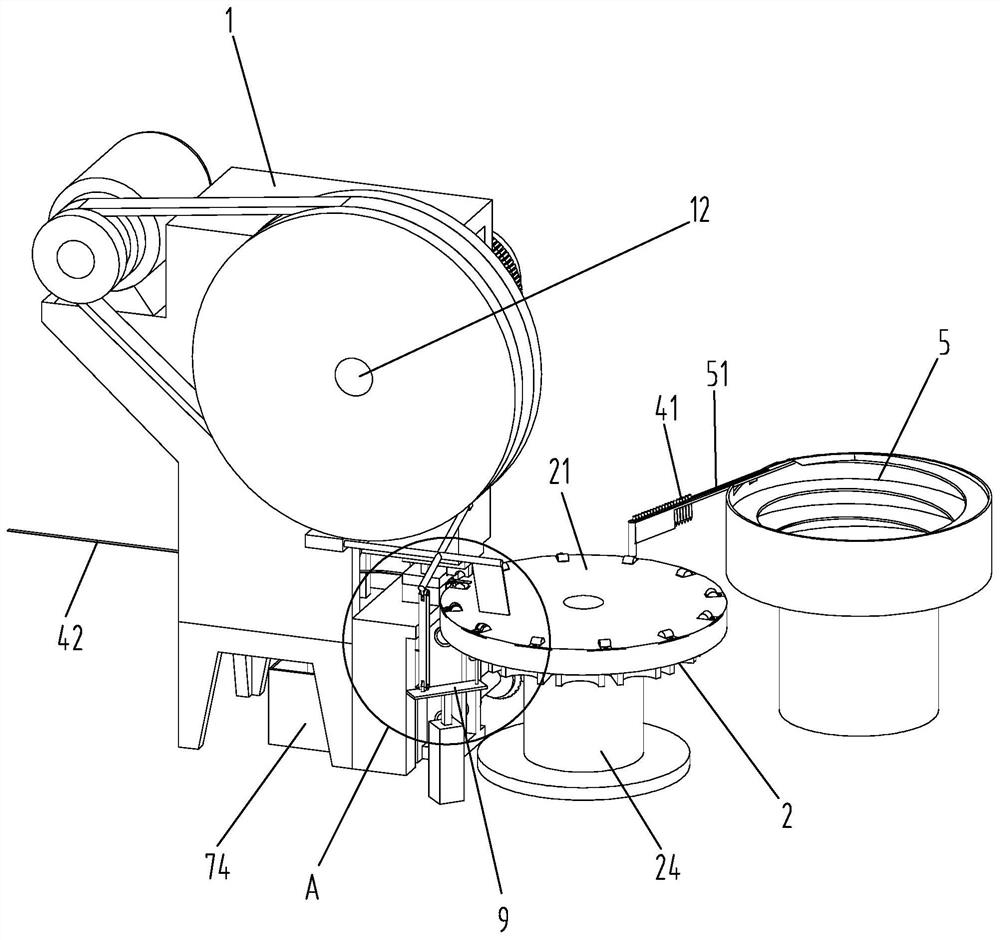

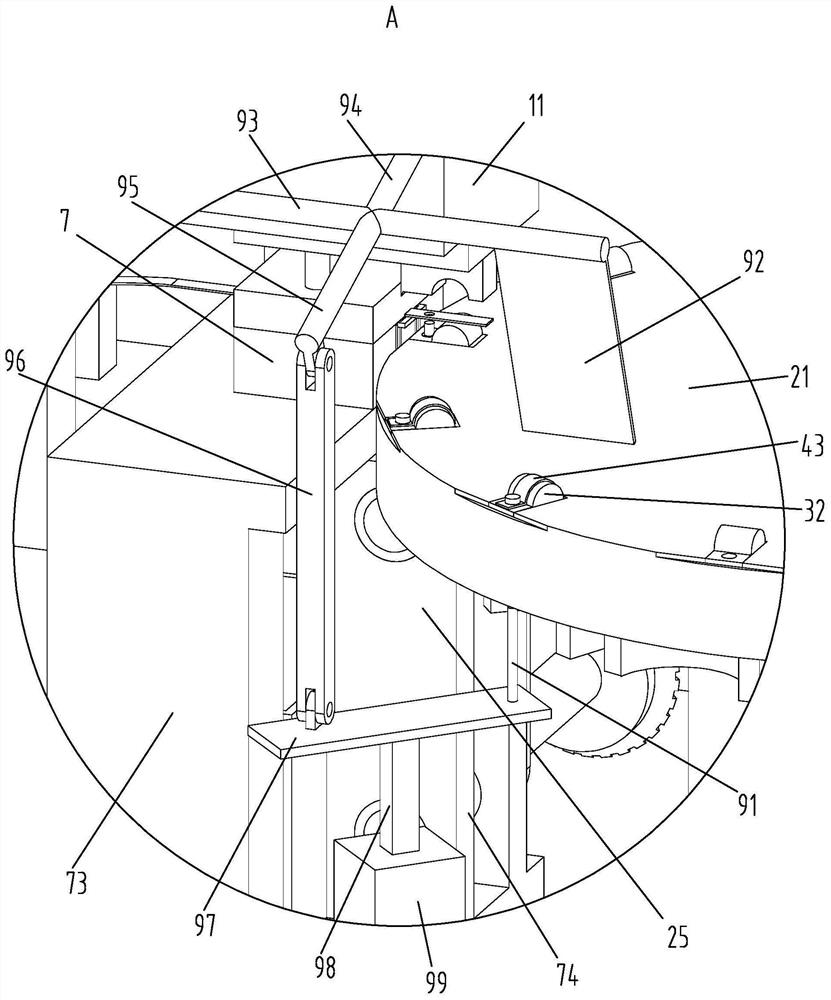

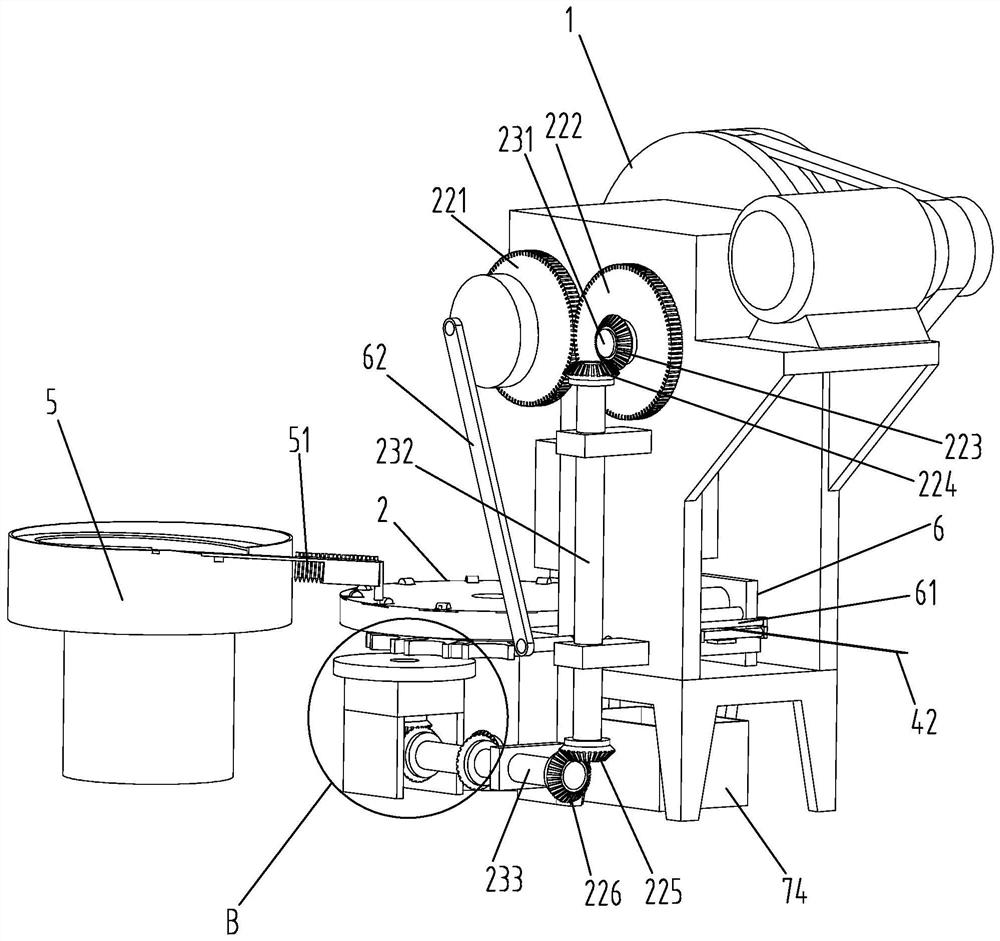

[0034] Such as Figure 1 to Figure 13 As shown, the hook nail automatic processing and forming equipment described in the present invention includes a punch press 1 and an intermittent rotary table 2, the lower end surface of the punch 11 of the punch press 1 is fixedly provided with a stamping forming male die 31, and the intermittent rotary table 2 A plurality of female molds 32 are fixed, and the intermittent rotating table 2 is used to intermittently rotate the female molds 32 to directly below the stamping male mold 31, and the female mold 32 is used to place the nail body blank 41 , when the sheet 42 enters between the stamping male die 31 and the female die 32, the stamping male die 31 will extrude the sheet 42 into a curved structure under the cooperation of the female die 32 The connecting arm 431 is riveted on the nail body blank 41 .

[0035] Through the setting of the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com