Core body for preventing particles from sliding and preparation method thereof

A core and particle technology, applied in the core field of sanitary absorbent products, can solve the problems of hot melt adhesive absorption and air permeability decrease, core delamination and SAP sliding accumulation, SAP uneven distribution, etc., to achieve product process design Reasonable, good water absorption and water retention performance, comfortable and light product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

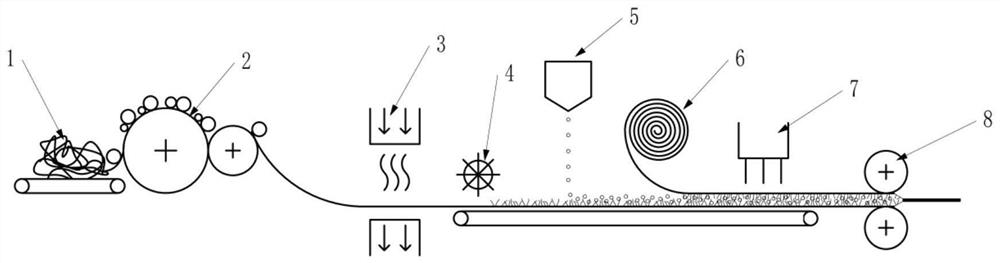

[0037] A kind of preparation method of the core body (such as figure 1 shown):

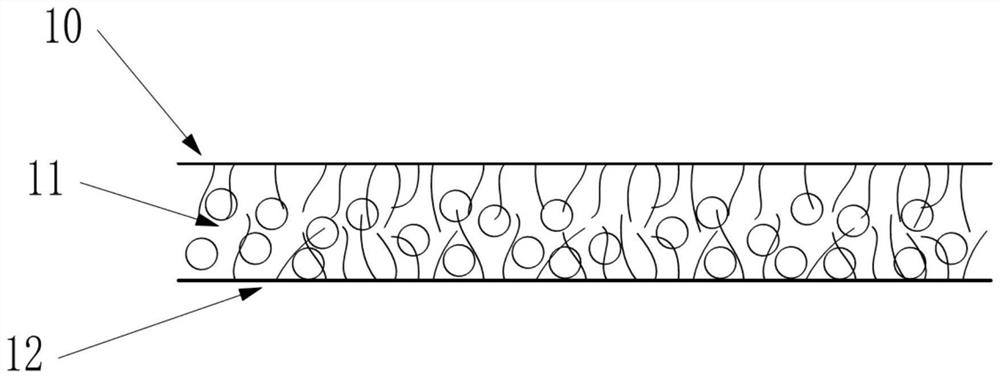

[0038] The fiber raw material uses hydrophilic ES fiber as the fiber raw material. First, the fiber is opened and carded by the carding machine 2, and the carded fiber web is reinforced by the hot air blower 3 to make the surface density 50g / m 2 The hot-air nonwoven fabric is processed by the fluffing mechanism 4, and the surface of the cloth forms hairiness as the core bottom layer 12. After the preparation, the SAP particles are sprinkled through the feeding hopper 5. Through effective control, the SAP particles can be Sprinkle evenly on the lower layer of hot air cloth. Then cover with 60g / m 2 Polyester and viscose mixed non-woven fabric roll (core body surface layer roll material 6), and then the cloth unrolled from the core body surface layer roll material 6 is subjected to acupuncture action, due to the characteristics of acupuncture can make the unrolled cloth Hairiness is formed under t...

Embodiment 2

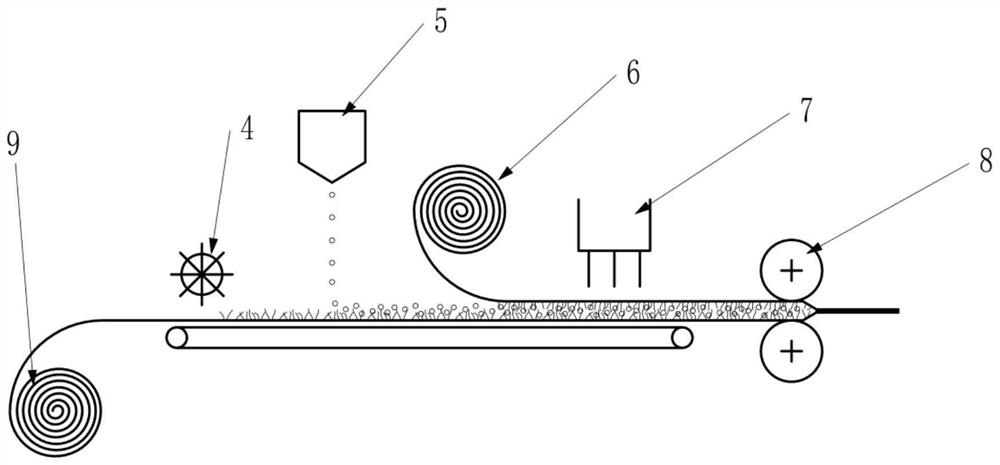

[0040] A kind of preparation method of the core body (such as figure 2 shown):

[0041] Start processing directly from the finished cloth, the production process is simplified, and the 60g / m 2 The spunlaced cloth used as the bottom cloth is processed by the raising mechanism and used as the core bottom layer 12. After the preparation, the SAP particles are sprinkled through the feeding hopper 5. Then cover with 60g / m 2 Polyester-cotton mixed non-woven fabric roll (core body surface layer coil 6), and then the cloth unrolled from the core body surface layer coil 6 is subjected to acupuncture action, and the needle punching action makes the unrolled cloth surface form a Hairiness, and under the action of acupuncture, the hairiness is inserted into the SAP particles of the middle layer to form a superabsorbent layer 11, and finally it is ultrasonically bonded by an ultrasonic bonding device 8 with a stripe pattern. This production line is more flexible and can be changed accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com