Threshold structure of electric vehicle

An electric vehicle, threshold technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

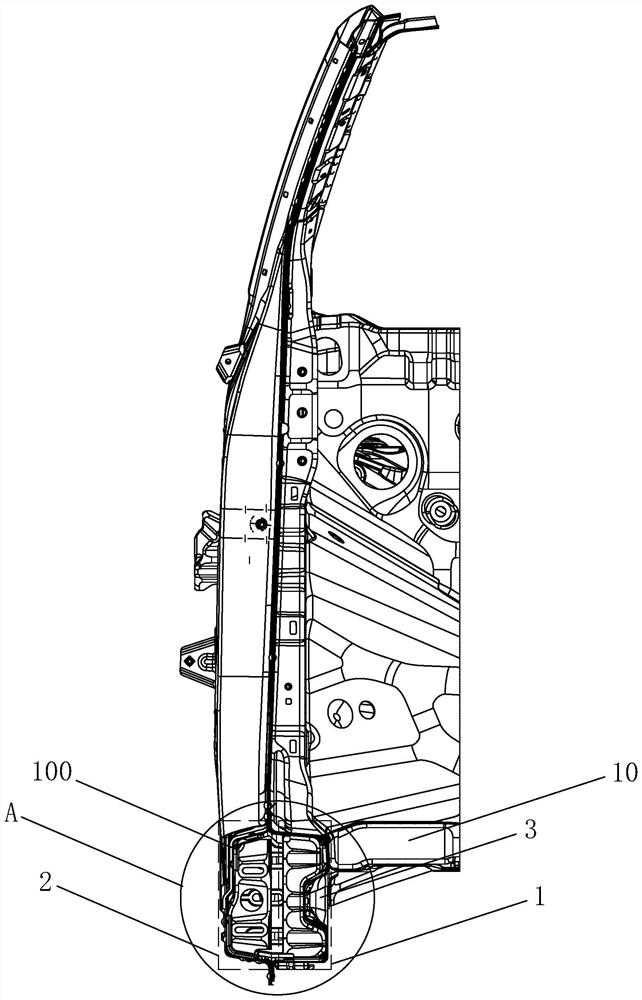

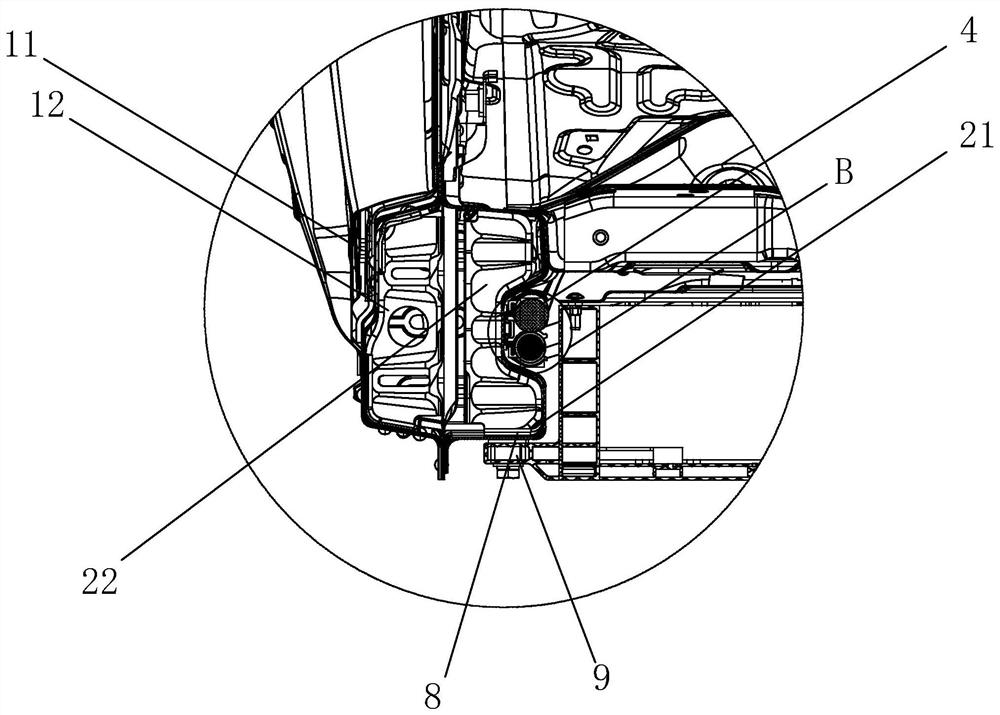

[0025] like figure 1 , 2 As shown, a threshold structure of an electric vehicle includes threshold components 100 arranged on both sides of the battery pack of the electric vehicle. The outer sill assembly 2 on the outside of the inner sill assembly is provided with an integrated wire harness accommodation chamber 3 between the sill assembly and the battery pack, and the integrated wire harness accommodation chamber is arranged inside the inner sill assembly. Compared with the traditional sill beam structure, the sill assembly of the combined structure has a richer combination scheme. Through the cooperation of the inner sill assembly and the outer sill assembly, the side impact force transmission and collapse energy absorption that a single sill beam does not have can be realized. Function, when the outer door sill assembly is damaged but the inner door sill assembly is not damaged, only the outer door sill assembly needs to be repaired and replaced, which improves the mater...

Embodiment 2

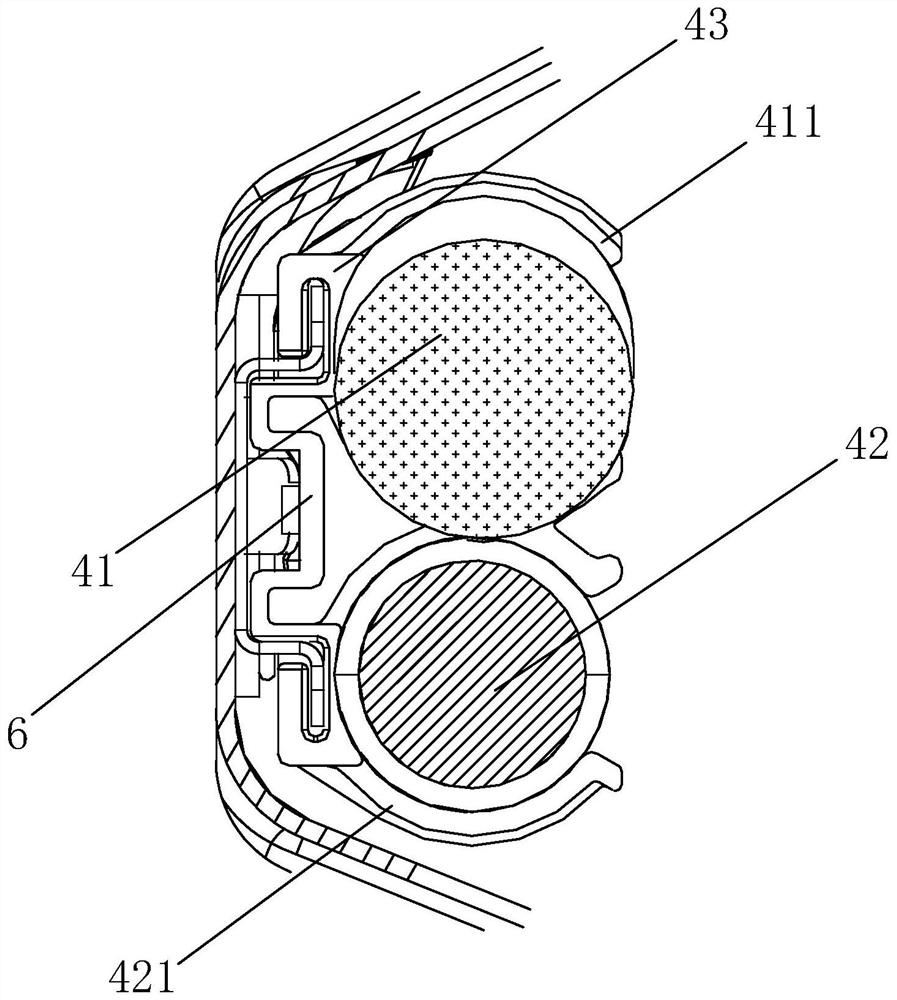

[0032] The difference from Embodiment 1 is that the protective layer in this embodiment does not use a sleeve made of hard material, but adopts a surrounding airbag component, and the protective layer includes a number of micro airbags 7 evenly arranged around it. like Figure 4 As shown, the surrounding airbag assembly plays a certain buffering role when the door sill assembly is subjected to side impact force, and the 360° buffer protection of the pipeline group is realized through the micro airbag arranged around the pipeline group.

[0033] A safety chamber 71 is provided on the side of the micro-airbag away from the pipeline group, and a wall breaking member 72 is provided in the safety chamber. The safety cavity is an open structure. When the micro-airbag is subjected to external pressure, it is determined according to the pressure whether the broken wall part installed on the inside touches the top of the safe cavity. When the external force is so large that the broken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com