Constant-speed nozzle for thermal deaerator

A thermal deaeration and nozzle technology, which is used in feedwater heaters, preheating, lighting and heating equipment, etc., can solve the problems of complex structure of constant speed nozzles, reduced spray effect and heat and mass transfer performance, and achieve good heat transfer. The mass transfer performance and heat transfer performance are superior and reliable, and the effect of easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

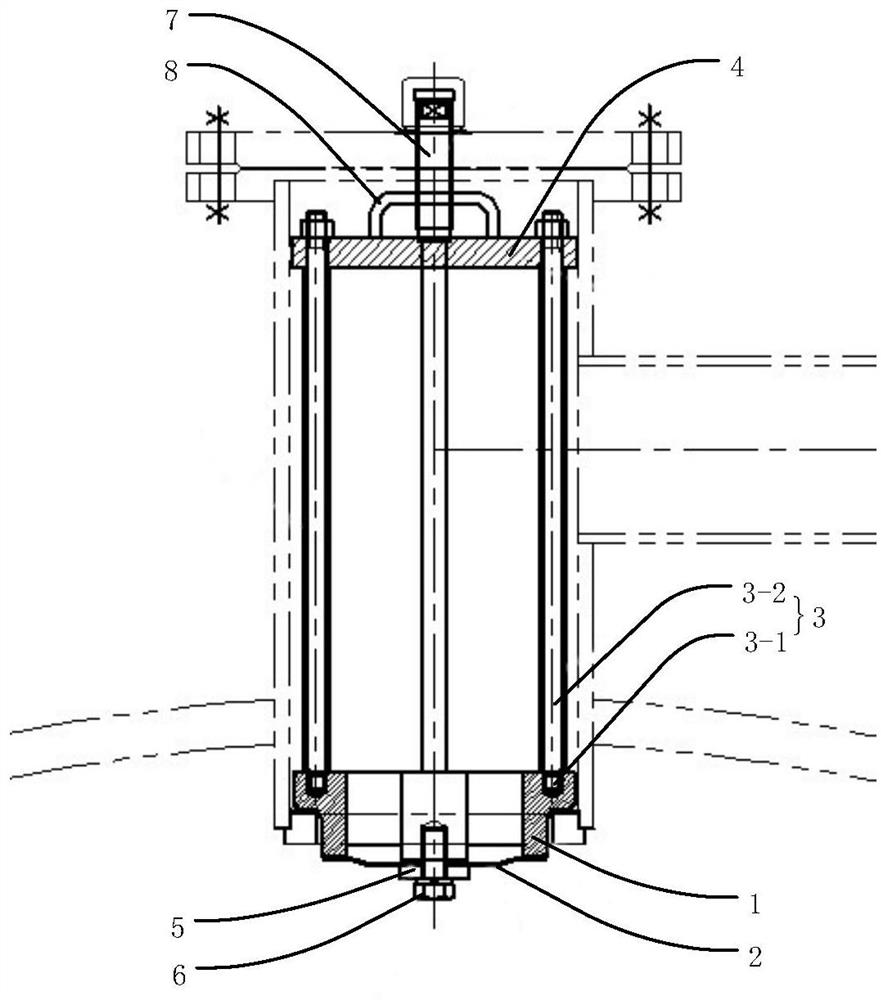

[0015] Embodiment 1, a constant velocity nozzle for a thermal deaerator in this embodiment includes a valve seat 1, a disc 2, at least two connecting rods 3 and a valve cover 4;

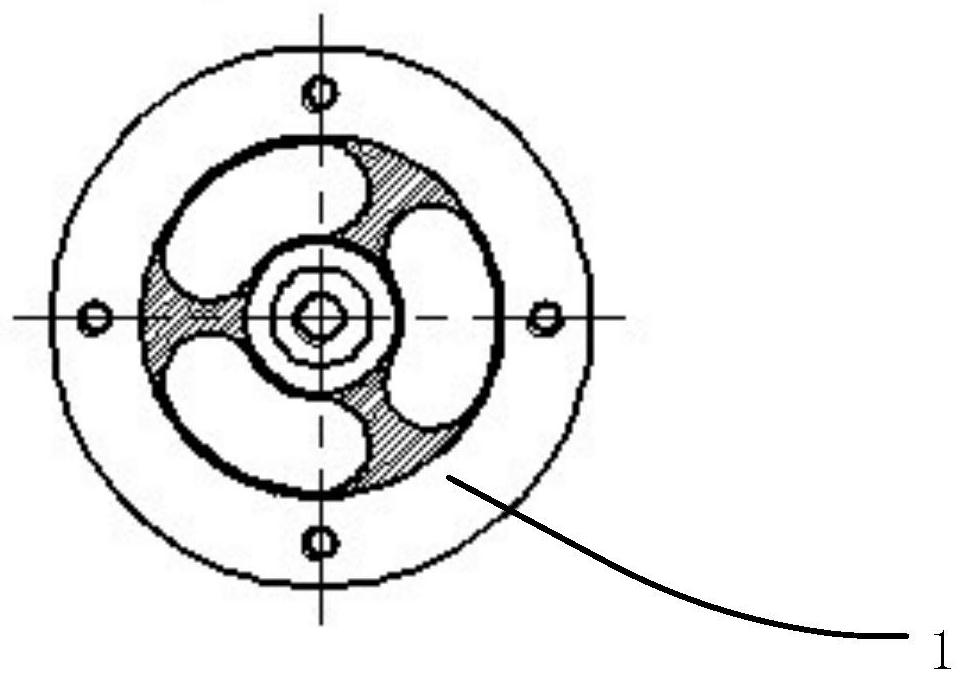

[0016] The valve seat 1 is annular, and the middle part of the valve seat 1 is provided with a disc support boss, and the side wall of the disc support boss is connected and fixed with the inner side wall of the valve seat 1 through connecting ribs;

[0017] The disc 2 is located under the valve seat 1, the center of the disc 2 is fixed to the bottom of the disc support boss, and the edge of the disc 2 is closely attached to the bottom of the valve seat 1;

[0018] The valve cover 4 is located above the valve seat 1 , and the valve cover 4 is fixed to the valve seat 1 through at least two connecting rods 3 .

[0019] Specifically, the valve seat 1, the disc 2, at least two connecting rods 3 and the valve cover 4 are all made of stainless steel.

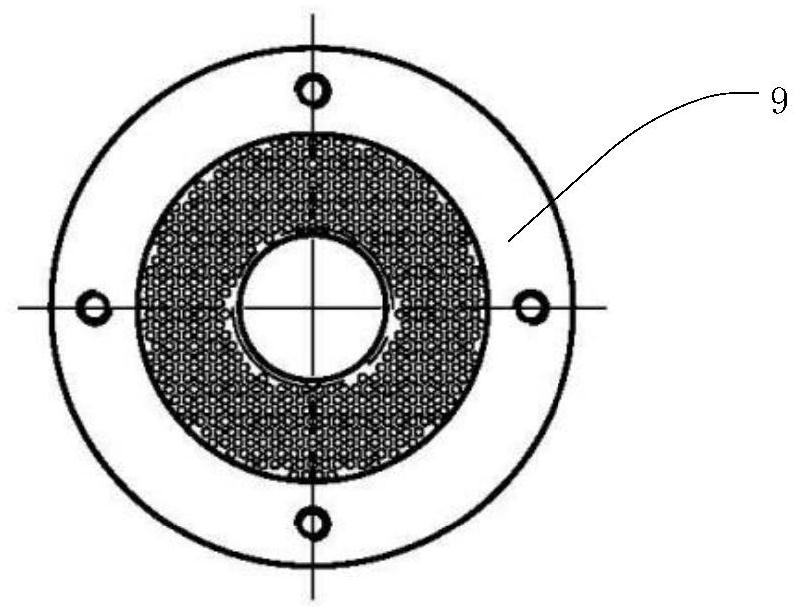

[0020] like figure 2 As shown, there are at least t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com