Environment-friendly rat-proof and ant-proof plastic insulation control cable

A technology for controlling cable and plastic insulation, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems that cables do not have anti-rodent and anti-term effects, power interruption of cable lines, and shortened service life of cables, etc. , Improve the service life, the effect of the stability of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An environment-friendly anti-rodent and ant-proof plastic insulated control cable, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 5 parts of anti-rodent and ant filler, 5 parts of impact-resistant filler, 1 part of di-n-butyl sebacate, N-ring 2 parts of hexyl p-ethoxyaniline;

[0031] The insulated control cable is made by the following steps:

[0032] Step S1: Heat the PVC resin at a temperature of 140°C until the PVC plastic is completely melted, add rodent-proof fillers and impact-resistant fillers, mix for 10 minutes, then add di-n-butyl sebacate and N- Cyclohexyl p-ethoxyaniline, continue mixing for 15min, to obtain rubber material;

[0033] Step S2: Compress the rubber material at a temperature of 140°C to obtain a rubber sheet with a thickness of 3 mm, then cut it into pellets to obtain rubber granules, and add the rubber granules to the five-stage single screw, and the temperature in the five stages is 130°C , 140°C, 155°C, ...

Embodiment 2

[0047] An environment-friendly anti-rodent and ant-proof plastic insulated control cable, comprising the following raw materials in parts by weight: 110 parts of PVC resin, 6 parts of anti-rodent and ant filler, 6 parts of impact-resistant filler, 2 parts of di-n-butyl sebacate, N-ring 3 parts of hexyl p-ethoxyaniline;

[0048] The insulated control cable is made by the following steps:

[0049] Step S1: Heat the PVC resin at a temperature of 140°C until the PVC plastic is completely melted, add rodent-proof fillers and impact-resistant fillers, mix for 10 minutes, then add di-n-butyl sebacate and N- Cyclohexyl p-ethoxyaniline, continue mixing for 15min, to obtain rubber material;

[0050] Step S2: Compress the rubber material at a temperature of 140°C to obtain a rubber sheet with a thickness of 3 mm, then cut it into pellets to obtain rubber granules, and add the rubber granules to the five-stage single screw, and the temperature in the five stages is 130°C , 140°C, 155°C,...

Embodiment 3

[0064] An environment-friendly anti-rodent and ant-proof plastic insulated control cable, comprising the following raw materials in parts by weight: 120 parts of PVC resin, 8 parts of anti-rodent and ant filler, 8 parts of impact-resistant filler, 3 parts of di-n-butyl sebacate, N-ring 5 parts of hexyl p-ethoxyaniline;

[0065] The insulated control cable is made by the following steps:

[0066] Step S1: Heat the PVC resin at a temperature of 145°C until the PVC plastic is completely melted, add rodent-proof fillers and impact-resistant fillers, mix for 15 minutes, then add di-n-butyl sebacate and N- Cyclohexyl p-ethoxyaniline, continue mixing for 20min, to obtain rubber material;

[0067] Step S2: Compress the rubber material at a temperature of 145°C to obtain a rubber sheet with a thickness of 5 mm, then cut it into pellets to obtain rubber granules, add the rubber granules to the five-stage single-screw, and the temperature in the five stages is 130°C , 140°C, 155°C, 140...

PUM

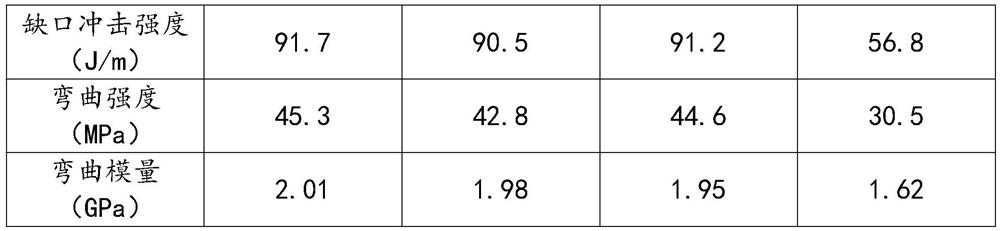

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com