Rat-proof and termite-proof optical cable

A technology of anti-rat and anti-termite layer and optical cable, which is applied in the field of cables and electric power, can solve the problems of narrow temperature processing range, cleanliness requirements, limited aluminum strip strength, and non-environmental protection, etc., and achieves good and convenient anti-rodent and anti-termite effects Production and manufacturing, the effect of low cost of optical cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

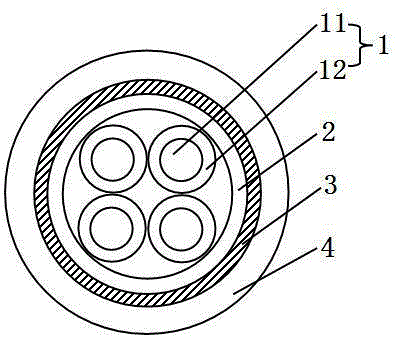

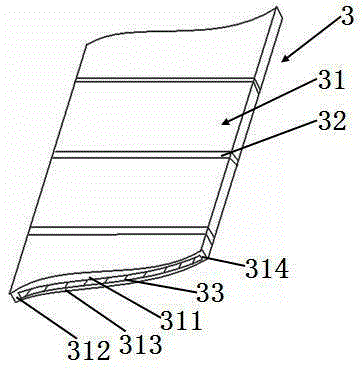

[0032] please see figure 1 and figure 2, a rodent-proof and termite-proof optical cable, which includes a plurality of optical cable units 1, an inner sheath 2 covering a plurality of cable units, and an outer sheath 4 outside the inner sheath, characterized in that the inner sheath and There is also a rodent-proof and termite-proof layer 3 between the outer sheaths, and the rodent-proof and termite-proof layer 3 is composed of a sealed bag-like body 31 and a rat-proof and termite-proof part 33 located in the bag-like body; there are multiple bag-like bodies, Adjacent bags are separated by partitions 32; the thickness of the rodent and termite-proof layer is 0.20 mm to 0.80 mm; the rodent and termite-proof components are calcium carbonate, which exists in the bag-like bodies in the form of powder , the upper surface 311, the left surface 312, the lower surface 313, the right surface 314, and the front and rear surfaces of the bag-shaped body are gas and liquid-tight; the bag...

Embodiment 2

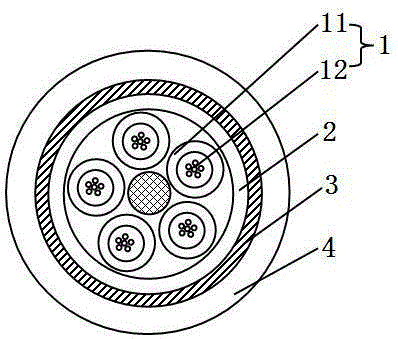

[0035] please see image 3 , and refer to figure 2 , a rodent-proof and termite-proof optical cable, basically the same as the implementation example 1, the difference is that: the optical cable unit 1 is composed of an optical fiber 11 located inside and a sleeve 12 located outside the optical fiber; the optical cable unit is twisted around the central strength member .

[0036] Of course, among the five cable units in the figure, some of them may be filled ropes, and the filled ropes are solid or hollow structures made of polyethylene or polypropylene.

Embodiment 3

[0038] please see Figure 4 , and refer to figure 2 , a rodent-proof and termite-proof optical cable, which is basically the same as in Example 2, except that: there is a cushion layer 5 between the rodent-proof and termite-proof layer and the inner sheath; Wrapped outside the inner sheath, there is a partial overlap between the rear helix and the front helix when the helix is wrapped, and there is an overlapping overlap when the longitudinal wrap is used; the material of the cushion layer is nylon 6 or nylon 12 or nylon 66 .

[0039] Of course, the rodent-proof and termite-proof optical cable described in any of the above implementation examples includes a plurality of optical cable units 1, an inner sheath 2 covering the plurality of optical cable units, and an outer sheath outside the inner sheath 4. It is characterized in that there is a rodent-proof and termite-proof layer 3 between the inner protective layer and the outer protective layer. The rodent-proof and termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com