Production equipment and production method for hot galvanized packaging steel strip, and hot galvanized packaging steel strip

A production equipment, hot-dip galvanizing technology, applied in heat treatment equipment, hot-dip galvanizing process, other manufacturing equipment/tools, etc., which can solve the problem of being susceptible to corrosion, affecting the strength of the use of the packing steel belt, and the use environment of the packing steel belt. Instability and other problems, to achieve the effect of meeting the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the technical solution of the present invention, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

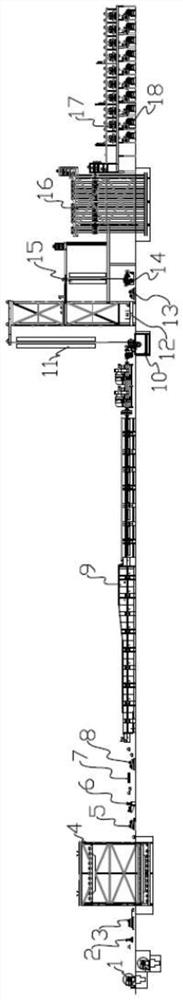

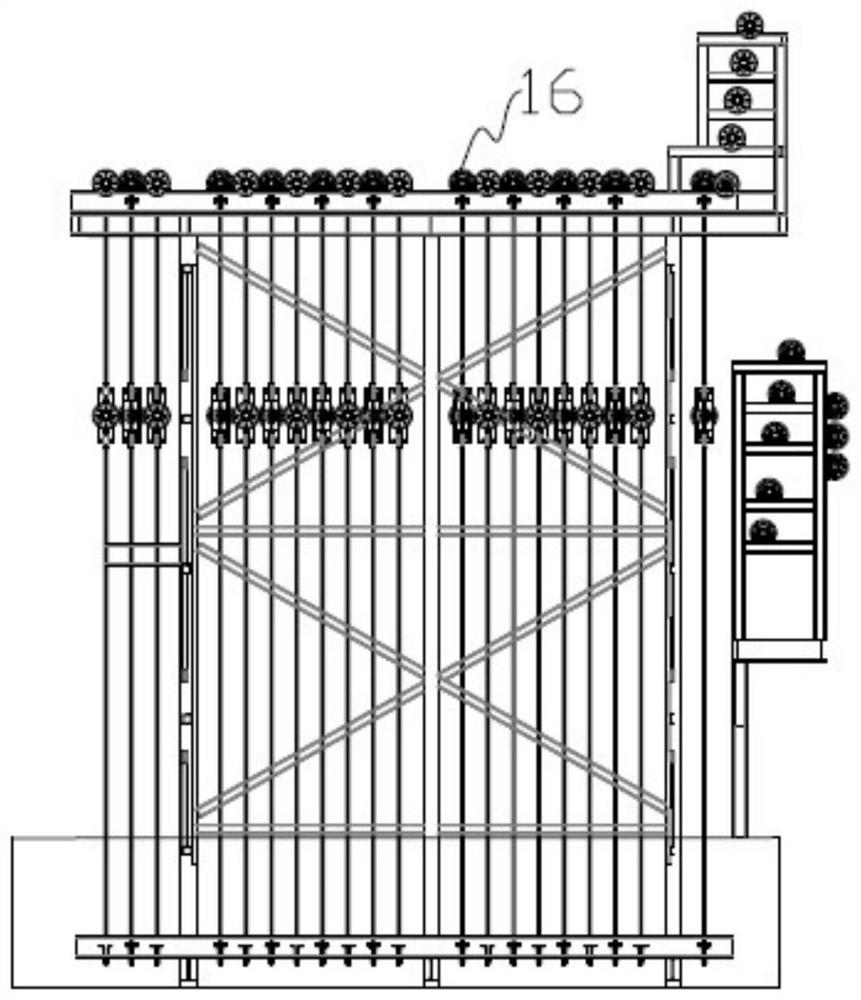

[0048] Such as Figure 1 to Figure 8 As shown, it includes uncoiler 1, butt welding machine 2, first tension device 3, feeding looper 4, second tension device 5, slitting and slitting machine 6, trimming machine 7, and third tension device arranged in sequence 8. Heat treatment furnace 9, hot melt zinc pot 10, air cooling device 11, water cooling device 12, fourth tension device 13, roller coater 14, drying and curing machine 15, blanking looper 16, fifth independent tension device 17 And coiler 18. In this embodiment, each device part is arranged in sequence according to the processing process of the steel stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com