Broad-spectrum anti-virus and anti-bacterial automobile lining

An antiviral and automotive technology, applied in vehicle parts, textiles and papermaking, transportation and packaging, etc., can solve the problem of lack of antiviral and bacteriostatic functions, and achieve the effect of large porosity, strong absorption and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

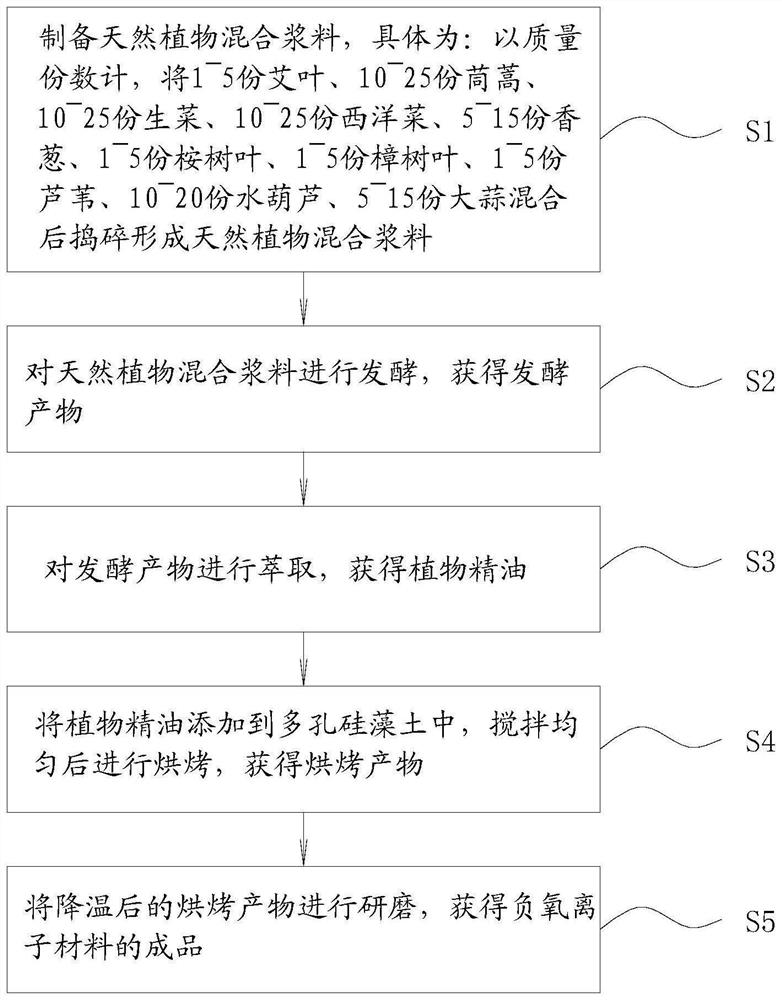

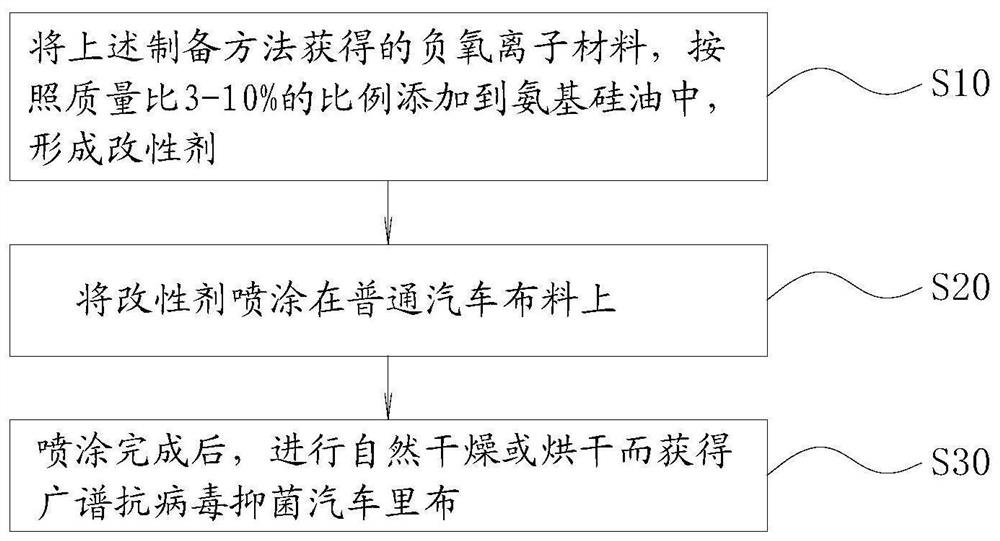

[0030] See attached figure 1 , the preparation method of a kind of antiviral antibacterial negative oxygen ion material provided by the invention, comprises the following steps:

[0031] S1: Prepare natural plant mixed slurry, specifically: in terms of parts by mass, 1 to 5 parts of Artemisia argyi, 10 to 25 parts of Chrysanthemum chrysanthemum, 10 to 25 parts of lettuce, 10 to 25 parts of watercress, and 5 to 15 parts of chives , 1 to 5 parts of eucalyptus leaves, 1 to 5 parts of camphor leaves, 1 to 5 parts of reeds, 10 to 20 parts of water hyacinth, and 5 to 15 parts of garlic are mixed and mashed to form a natural plant mixed slurry. , Chrysanthemum chrysanthemum, lettuce, watercress, chives, eucalyptus leaves, camphor leaves extract chlorophyll.

[0032] S2: Ferment the natural plant mixed slurry to obtain a fermentation product, specifically: put the natural plant mixed slurry in a sealed stainless steel fermentation tank for fermentation, and control the fermentation t...

Embodiment 1

[0045] S1: Prepare natural plant mixed slurry; specifically: in terms of mass parts, 2 parts of mugwort leaves, 20 parts of Chrysanthemum chrysanthemum, 20 parts of lettuce, 20 parts of watercress, 10 parts of chives, 2 parts of eucalyptus leaves, 2 parts of camphor leaves , 2 parts of reed, 15 parts of water hyacinth and 7 parts of garlic are mixed and mashed to form a natural plant mixed slurry.

[0046] S2: Ferment the natural plant mixed slurry to obtain a fermentation product; specifically: put the natural plant mixed slurry in a sealed stainless steel fermentation tank for fermentation, and control the fermentation time to 30 days. The fermentation process started from the third day, and the stainless steel fermenter was vented twice a day.

[0047] S3: extracting the fermentation product to obtain plant essential oil; specifically: using edible alcohol with a purity of 95% as an extract to extract the fermentation product, and the mass ratio of the edible alcohol to the...

Embodiment 2

[0051] S1: Prepare natural plant mixed slurry; specifically: in terms of mass parts, 3 parts of mugwort leaves, 18 parts of Chrysanthemum chrysanthemum, 18 parts of lettuce, 18 parts of watercress, 12 parts of chives, 3 parts of eucalyptus leaves, and 3 parts of camphor leaves , 3 parts of reeds, 12 parts of water hyacinth and 10 parts of garlic are mixed and mashed to form the natural plant mixed slurry.

[0052] S2: Ferment the natural plant mixed slurry to obtain a fermentation product; specifically: put the natural plant mixed slurry in a sealed stainless steel fermentation tank for fermentation, and control the fermentation time to 30 days. The fermentation process started from the third day, and the stainless steel fermenter was vented twice a day.

[0053] S3: extracting the fermentation product to obtain plant essential oil; specifically: using edible alcohol with a purity of 95% as an extract to extract the fermentation product, and the mass ratio of the edible alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com