Reinforcing treatment method for steel structure bridge

A processing method and steel structure technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve problems such as low compactness of steel frame connection parts, variable height, vertical steel frame deflection, etc., to improve the quality of fixed-point welding , Improve the degree of fit and increase the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

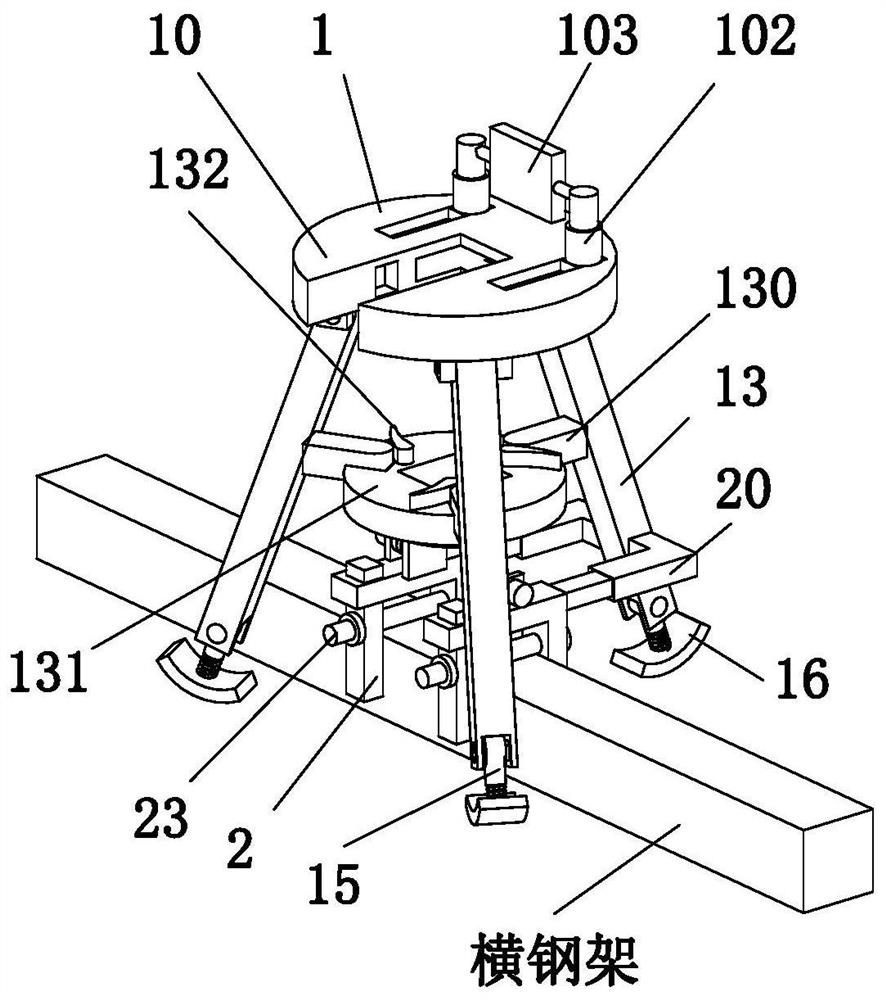

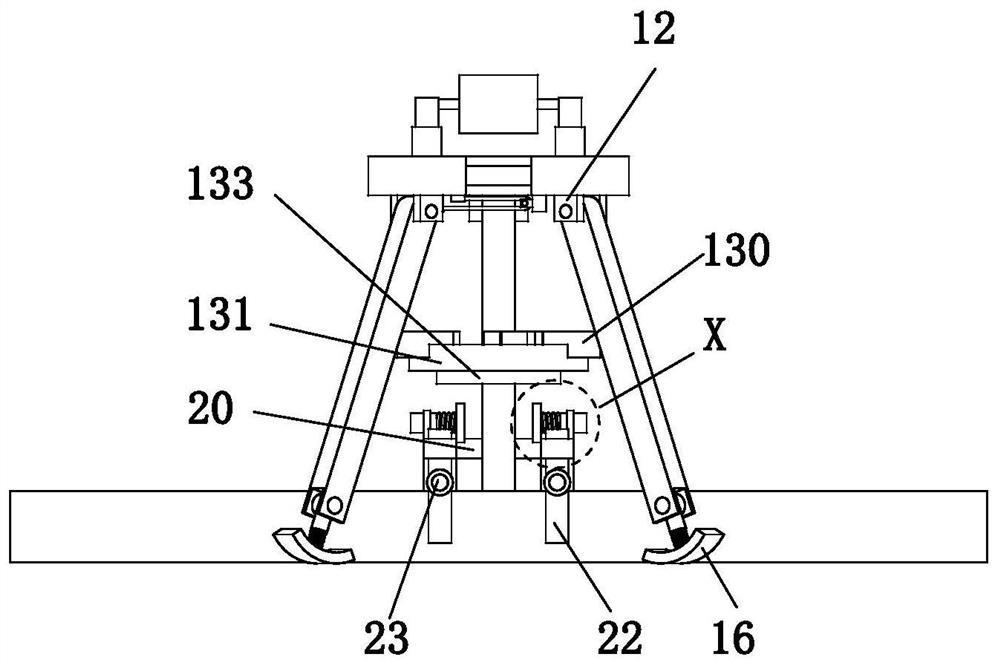

[0036] like Figure 1 to Figure 9 As shown, a steel structure bridge reinforcement processing method, which uses a steel structure bridge reinforcement processing device, the steel structure bridge reinforcement processing device includes a main body 1 and a fixing mechanism 2, using the above steel structure bridge reinforcement processing device to carry out steel The specific treatment methods for structural bridge reinforcement are as follows:

[0037] S1. The installation position is in place: the struts 13 ferrules are manually placed on the horizontal steel frame on the existing working ground, and the struts are pushed to move to the corresponding positions on the horizontal steel frame. The struts drive the round table 10 to move synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com