A closed collection system for the overflow sewage of the torch water-sealed tank

A collection system and water-sealing tank technology, applied in piping systems, combustion types, lighting and heating equipment, etc., can solve the problem of increasing project cost, increasing the difficulty of water-sealing pipe operation and maintenance, and not meeting the environmental protection regulations of VOC fugitive emissions and other problems to achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

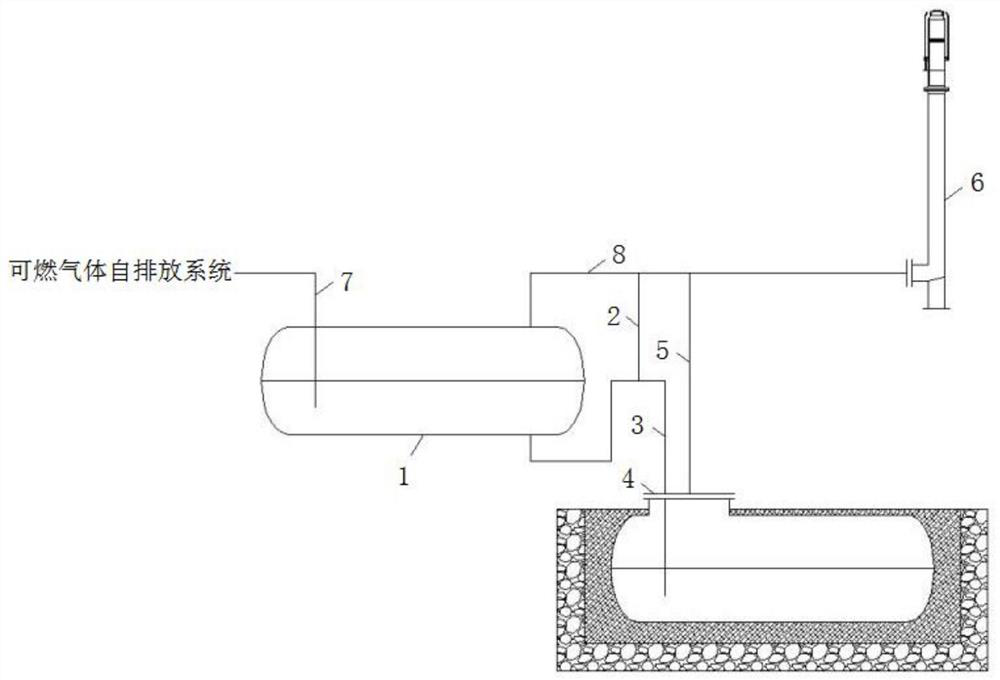

[0031] A closed collection system for the overflow sewage of a torch water sealing tank, such as figure 1 As shown, including the water sealing tank 1, the water sealing tank inlet pipe 7 and the water sealing tank outlet pipe 8 are installed on the top of the water sealing tank, the water sealing tank inlet pipe is connected to the combustible gas discharge system, and the water sealing tank outlet pipe is connected with the torch 6 , connect the inlet of a U-shaped overflow pipe 3 at the bottom of the water-sealing tank, insert the outlet of the U-shaped overflow pipe into the sewage tank 4, and connect a U-shaped overflow pipe between the high point of the U-shaped overflow pipe and the outlet pipe of the water-sealing tank The vacuum tube 2 is broken, and the top of the sewage tank is connected to the outlet pipe of the water-sealing tank or to the water-sealing tank through a gas phase balance pipe 5.

Embodiment 2

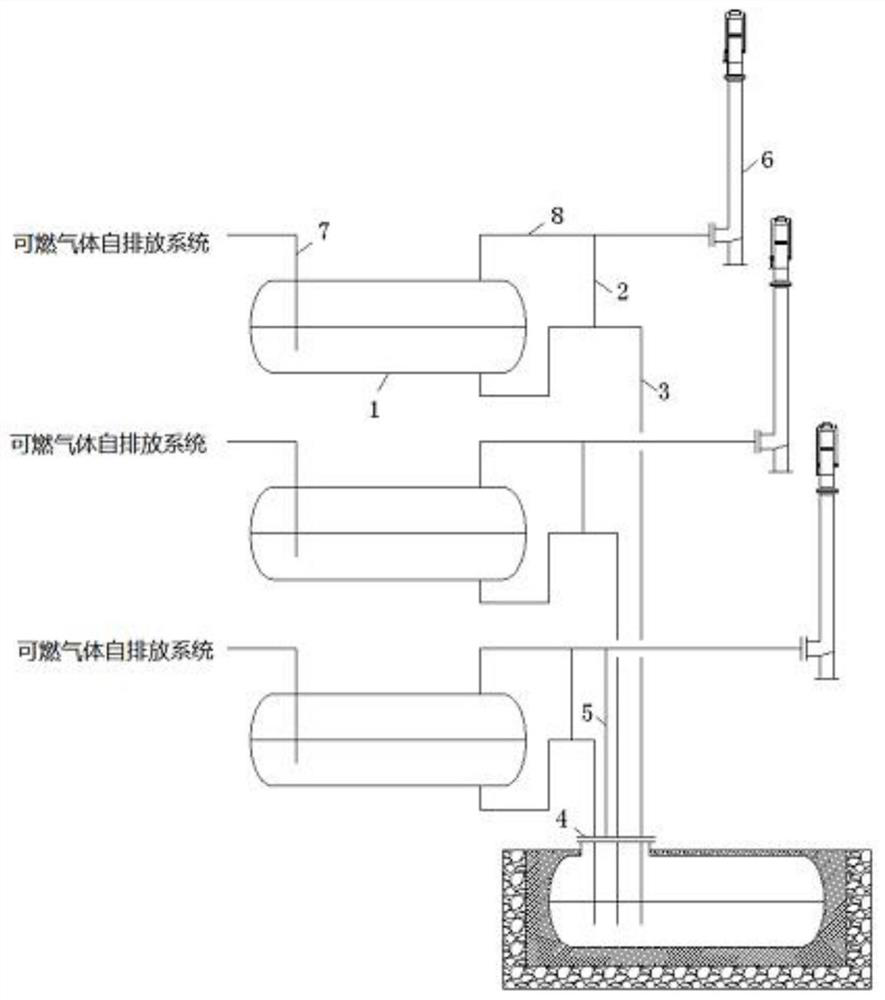

[0033] A multi-discharge system flare water sealing tank overflow sewage closed collection system, such as figure 2As shown, including a plurality of water-sealing tanks 1, a water-sealing tank inlet pipe 7 and a water-sealing tank outlet pipe 8 are installed on the top of each water-sealing tank, and each water-sealing tank inlet pipe is connected to a combustible gas discharge system, Each water-sealing tank outlet pipe is connected with a torch 6, the bottom of each water-sealing tank is connected with the inlet of a U-shaped overflow pipe 3, and the outlets of all U-shaped overflow pipes are inserted into a sewage tank 4, A vacuum breaking pipe 2 is connected between the high point of each U-shaped overflow pipe and its corresponding water sealing tank outlet pipe, and the top of the sewage tank is connected with one of the water sealing tank outlet pipes or the The water sealing tank is connected to discharge the combustible gas in the sewage tank 4 .

[0034] The sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com