Heat pump heating system based on heating pipe network

A heating pipe network and heating system technology, which is applied in hot water central heating systems, heating systems, household heating and other directions, can solve the difficulty of network access in new communities, the saturated transmission and distribution capacity of heating pipe networks, and the low utilization rate of heating water energy. and other problems, to achieve the effect of improving energy utilization, realizing heat recovery, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

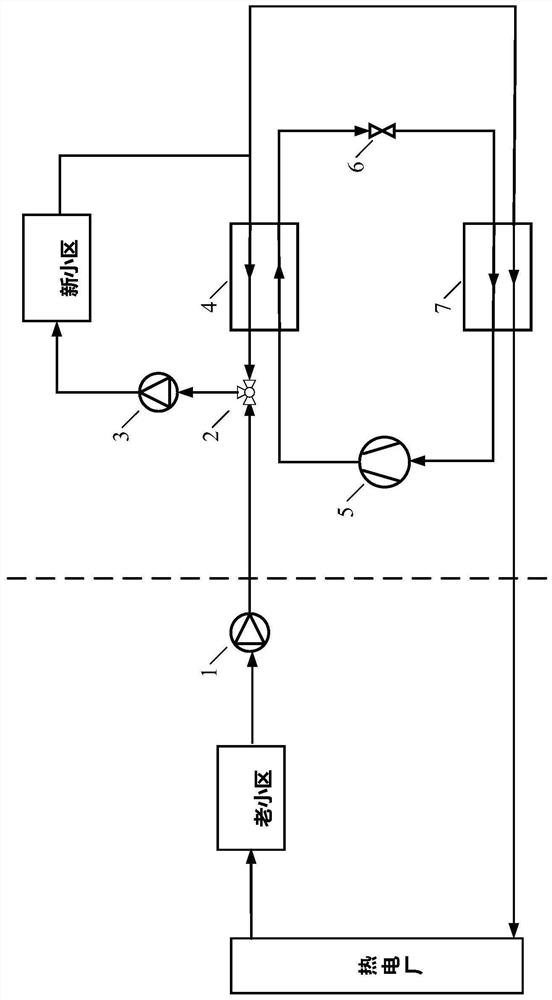

[0052] In this embodiment, it is a structural schematic diagram of heat pump + mixed water mode to realize heat recovery and heating, as shown in figure 2 shown, including:

[0053] Refrigerant circulation circuit: the condenser 4, throttling device 6, evaporator 7 and compressor 5 are connected in sequence through refrigerant pipes.

[0054] Heating water circulation loop: the inlet of the first water pump 1 is connected to the return pipe of the old community through water pipes, the first interface, the second interface, and the third interface of the water mixing valve 2 are respectively connected to the outlet of the first water pump 1 and the inlet of the second water pump 3 And the condenser 4 is connected through water pipes, the outlet of the second water pump 3 is connected with the water supply pipe of the new community through water pipes, the condenser 4, the evaporator 7, and the return water pipes of the new community are respectively connected to the three int...

Embodiment 2

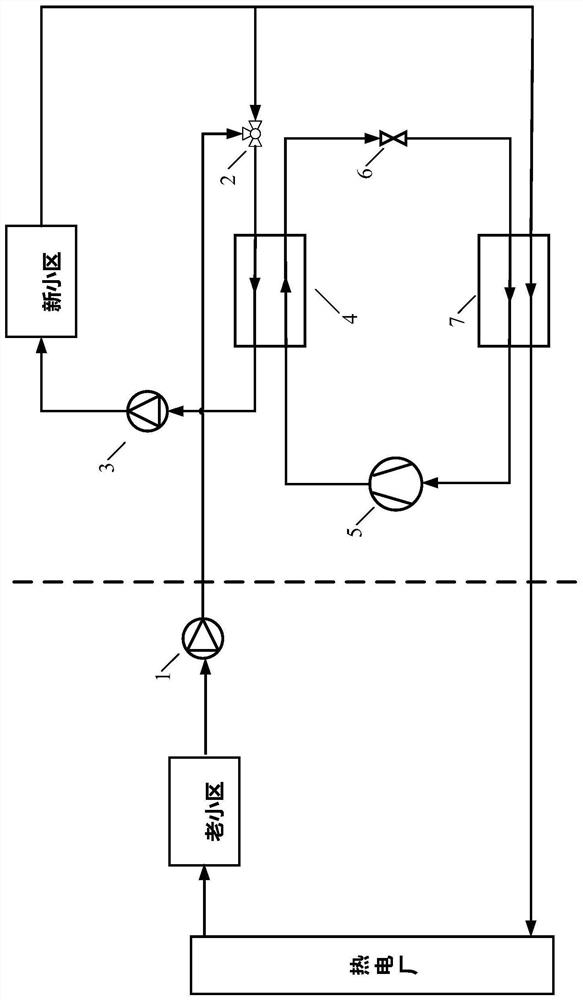

[0060] In this embodiment, it is a schematic structural diagram of using mixed water + heat pump mode to realize regenerative heating, as shown in image 3 As shown, the difference between it and Embodiment 1 is that the three ports of the water mixing valve are changed to be connected to the condenser 4, the first water pump 1, and the tee connecting the return pipe of the new community to the evaporator 7 through water pipes.

[0061] The difference from Example 1 during operation is that the medium-temperature water after the heating in the old district is changed to the medium-temperature water after the heating in the new district is mixed first and then enters the condenser 4 for heating.

Embodiment 3

[0063] In this embodiment, it is a schematic diagram of the structure of heat pump + plate heat exchanger to realize heat recovery and heating, as shown in Figure 4 shown.

[0064] Refrigerant circulation circuit: same as embodiment 1.

[0065] Heating water circulation loop: There are two heating water circulation loops: the heating water circulation loop and the new community water supply circulation loop. In the heating water circulation loop, the inlet and outlet ends of the first water pump 1 are respectively connected to the return water pipe of the old community and the evaporator 7 through water pipes. Plate heat exchange The evaporator 8 is respectively connected with the evaporator 7 and the return pipe of the heating pipe network through water pipes; in the water supply circulation loop of the new residential area, the inlet port of the second water pump 3, the condenser 4 and the plate heat exchanger 8 are respectively connected with the three interfaces of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com