Production equipment for paper diaper core body

A technology for producing equipment and diapers, which is applied in the fields of layered products, medical science, clothing, etc., can solve the problems of uncomfortable wearing, low water absorption, and large thickness of diapers, achieve uniform layout, save replacement time, and various patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

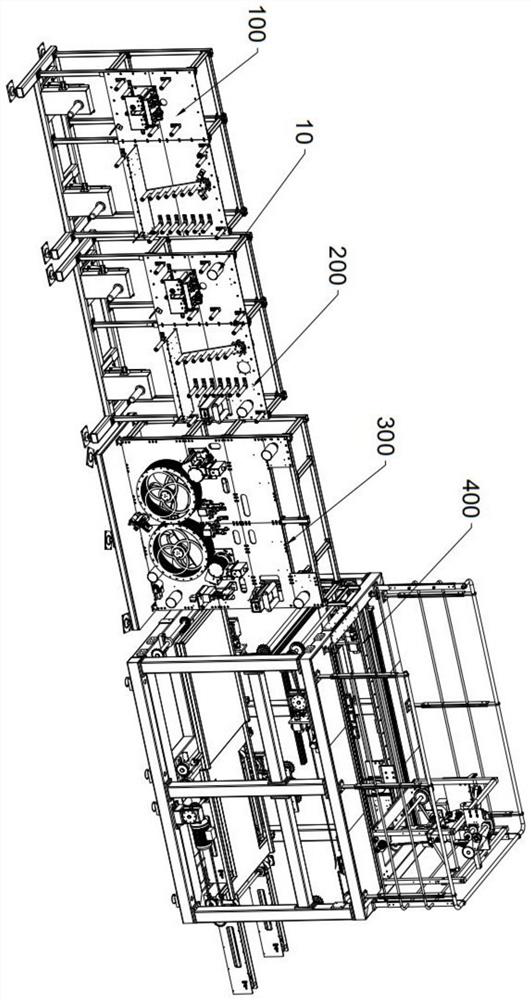

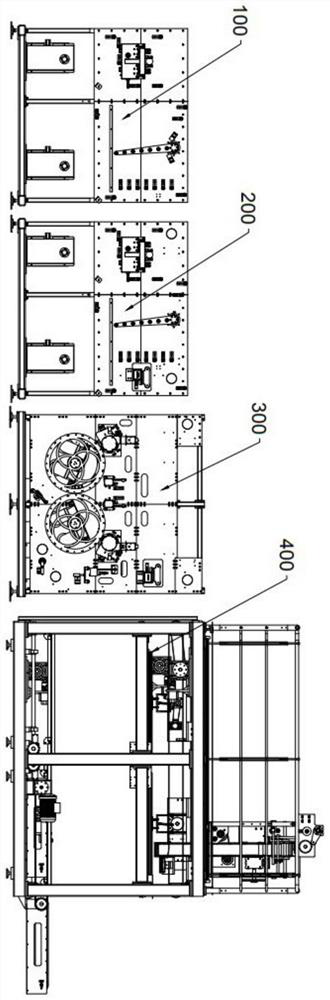

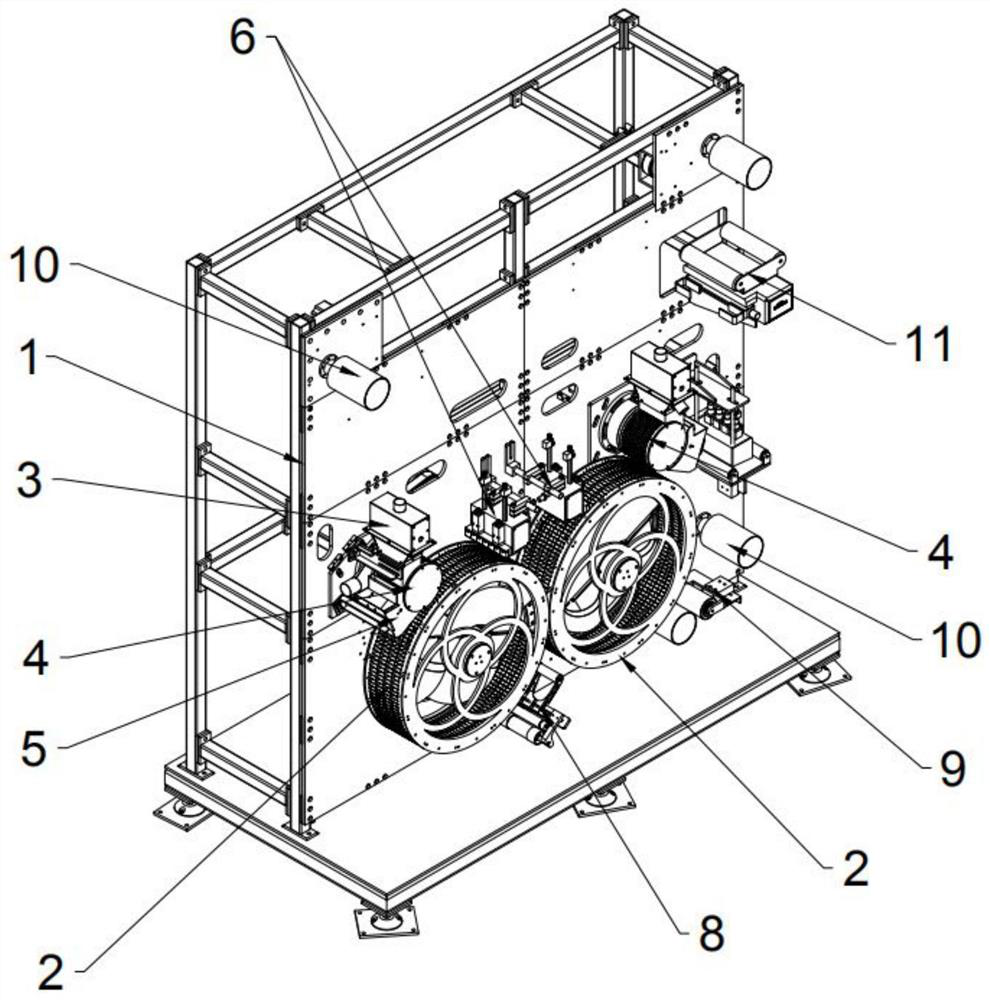

[0026] Such as Figure 1 to Figure 12 As shown, the production equipment of a diaper core according to the present invention is characterized in that it includes a first discharging mechanism 100, a second discharging mechanism 200, a composite mechanism 300 and a winding mechanism 400, and the composite mechanism 300 includes a compound frame 1, and two cloth distribution mechanisms are symmetrically arranged on the compound frame 1, each of which includes a roller assembly 2, and the roller assembly 2 is rotatably arranged on the compound frame 1, two groups The drum assembly 2 is arranged tangentially and at the same height, and also includes a lower material box assembly 3 arranged around the drum assembly 2, a molecular pump assembly 4, a scraping recovery assembly 5 and a glue spray assembly 6, and the drum assembly 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com