Gas inlet self-stirring type biological washing tower for waste gas treatment

A technology for biological washing and waste gas treatment, applied in the field of biological washing towers, can solve the problems of high cost, low decomposition efficiency, and many equipment used, and achieve the effects of reducing the use of equipment, improving reaction efficiency, and reducing waste gas treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

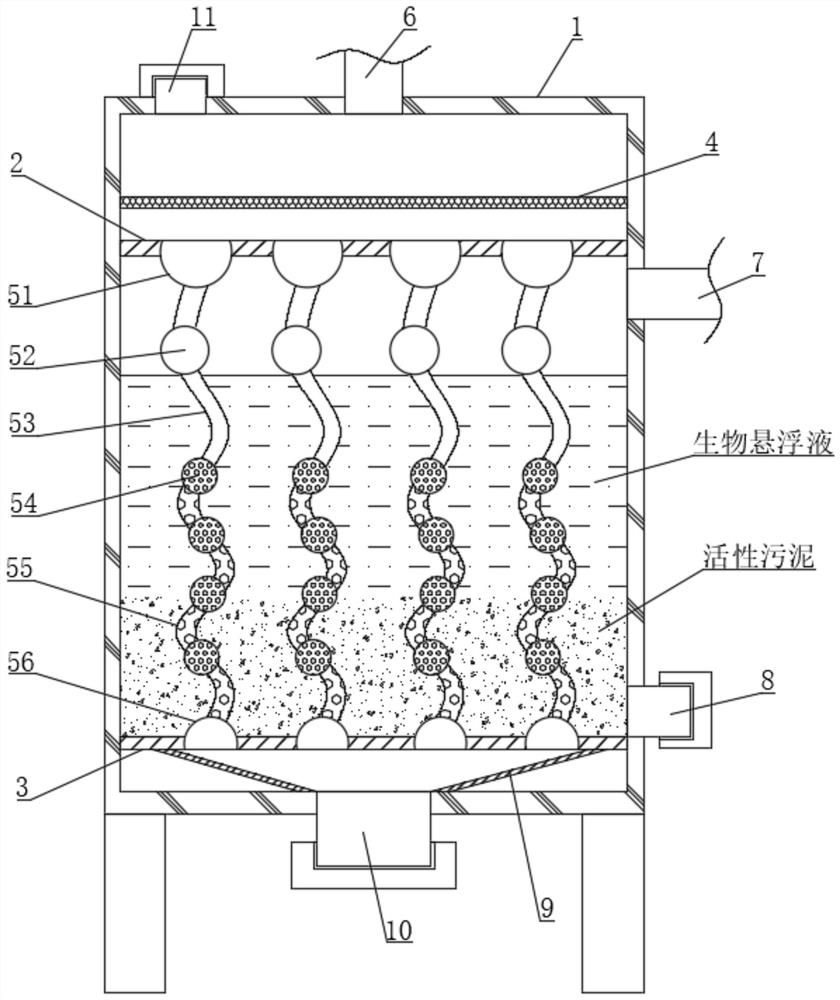

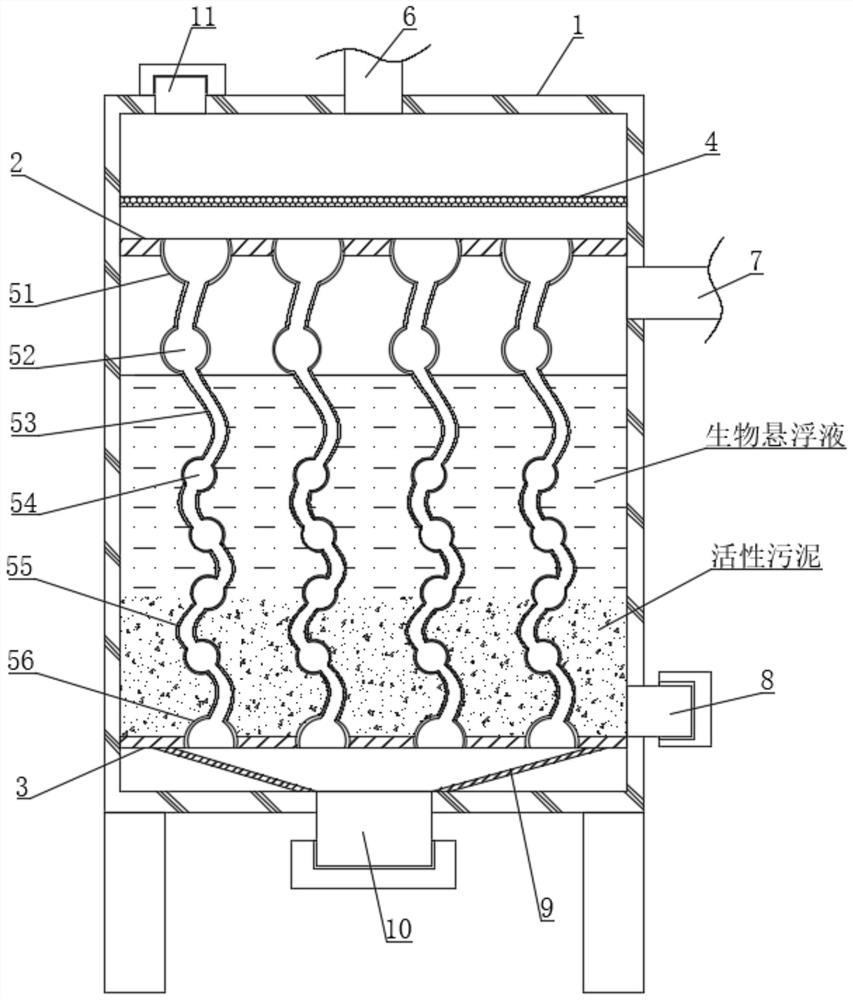

[0041] see figure 1 , an air-intake self-stirring biological scrubber for waste gas treatment, comprising a tower body 1, the inner wall of the tower body 1 is fixedly connected with an upper fixed plate 2 and a lower fixed plate 3 parallel to each other, and the upper fixed plate 2 is located at the lower fixed plate 3 The upper side of the upper fixed plate 3 is filled with activated sludge, the upper end of the activated sludge is filled with biological suspension, the biological suspension is located on the lower side of the upper fixed plate 2, between the upper fixed plate 2 and the lower fixed plate 3 It is connected with a plurality of uniformly distributed air diffuser soft columns.

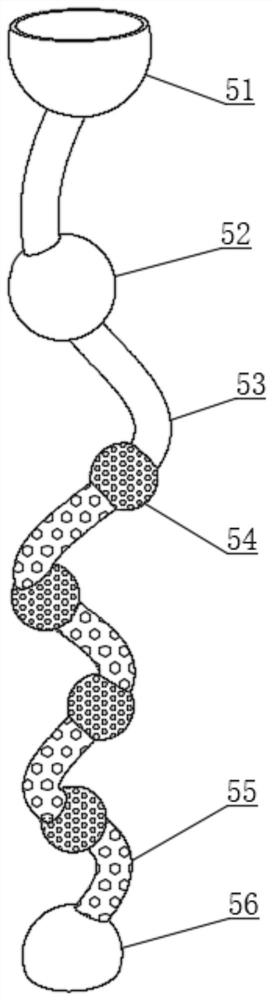

[0042] see figure 1 with figure 2 , the row of gas-dispersing soft columns includes a main hollow hemisphere 51 and an auxiliary hollow hemisphere 56, the main hollow hemisphere 51 runs through the upper fixed plate 2 and is fixedly connected with the interior of the upper fixed plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap