Rivet taking and placing mechanism, planar robot, rivet pressing device and rivet pressing system

A robot and rivet technology, applied in the fields of planar robots, riveting devices and riveting systems, and rivet pick-and-place mechanisms, can solve problems such as low efficiency, labor occupation, and easy installation errors, and achieve high processing efficiency, convenient control, and setting convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

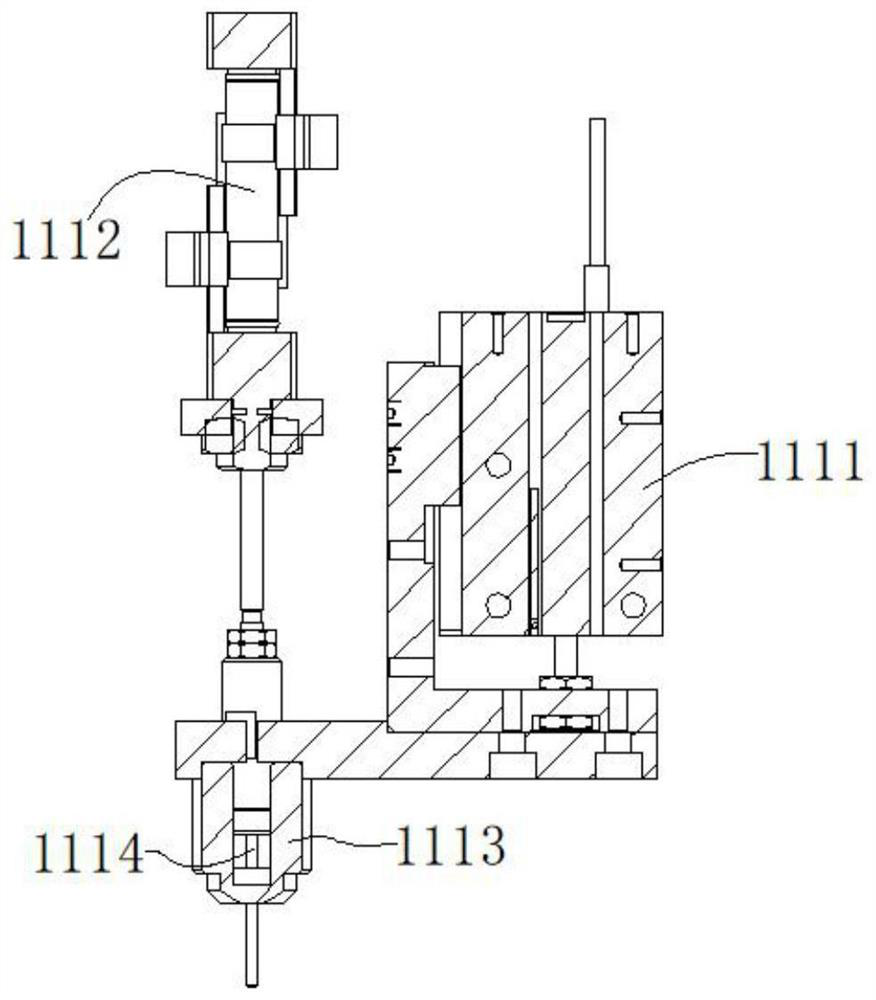

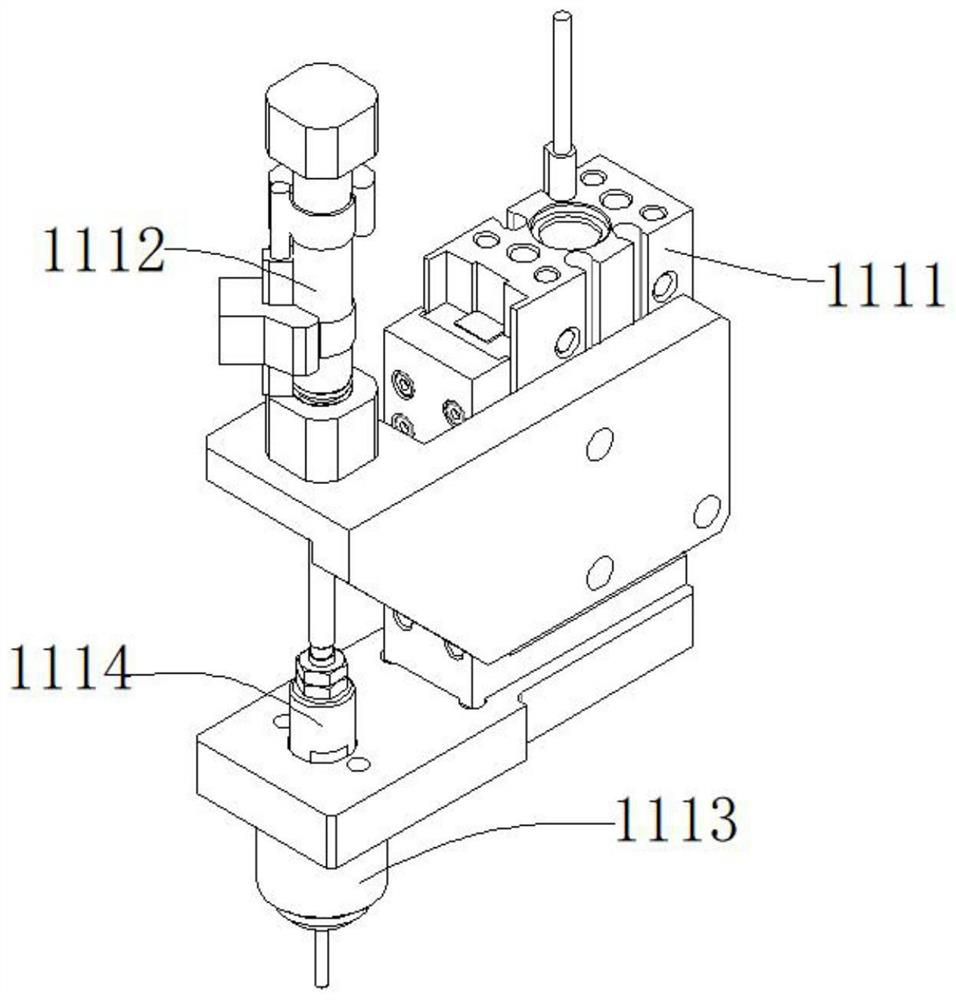

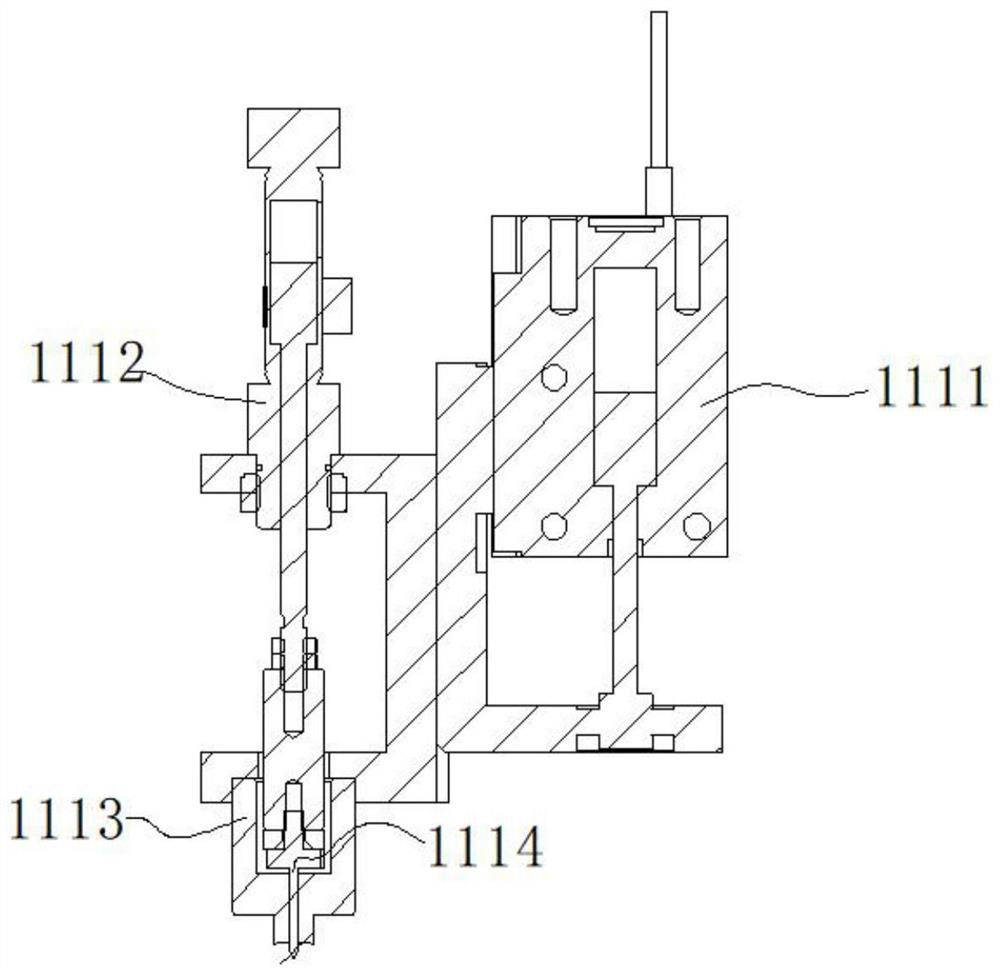

[0039] like figure 1 and figure 2 As shown, this embodiment provides a rivet pick-and-place mechanism, the first telescopic member 1111, the second telescopic member 1112, the sleeve 1113 and the vertical rod 1114, the sleeve 1113 is vertically arranged, and the middle part is provided with a vertical penetrating The through hole, the vertical rod 1114 is vertically arranged, and it passes through the through hole from top to bottom, the first telescopic member 1111 is in transmission connection with the sleeve 1113, and the second telescopic member 1112 The first telescopic member 1111 and / or the second telescopic member 1112 are connected in transmission with the vertical rod 1114, and are used to drive the vertical rod 1114 and the slider to move relatively vertically so that the vertical rod The lower end of 1114 extends out of the sleeve 1113 or is received into the sleeve 1113;

[0040] When the rivet is a solid rivet, the lower end of the sleeve 1113 is magnetic (mag...

Embodiment 2

[0045] like image 3 and Figure 4 As shown, with embodiment 1, the difference is that when the rivet is a hollow rivet, the lower end of the vertical rod 1114 has magnetism (magnets can be installed directly or the lower end of the vertical rod can be magnetized by installing a magnet), and the sleeve 1113 The lower end of the lower end is made of non-magnetic material, and the second telescopic member 1112 drives the vertical rod 1114 to move down to its lower end to protrude from the lower end of the sleeve 1113 and extend into the inner hole of the hollow rivet The hollow rivet is sucked inside, and the first telescopic member 1111 is used to drive the sleeve 1113 to move downward relative to the vertical rod 1114 so as to suck the hollow rivet at the lower end of the vertical rod 1114. Pushing away from the lower end of the vertical rod 1114 has a simple structure, and the adsorption is achieved by magnetizing the lower end of the sleeve or the lower end of the vertical ...

Embodiment 3

[0050] like Figure 5 As shown, this embodiment provides a planar robot, including a planar robot arm 112, a mounting frame 113 and a plurality of rivet pick-and-place mechanisms 111 as described in claim 1 and / or embodiment 2, and the mounting frame 113 is installed At the driving end of the planar mechanical arm 112, a plurality of rivet pick-and-place mechanisms 111 are installed on the mounting frame 113, and are distributed at intervals on the mounting frame 113, so that they can be driven by the planar mechanical arm through the mounting frame. Multiple rivet pick-and-place mechanisms move three-dimensionally. Thereby making its automation further improved.

[0051] Wherein, the plurality of rivet pick-and-place mechanisms on each mounting frame may be the rivet pick-and-place mechanisms corresponding to Embodiment 1 or the rivet pick-and-place mechanisms corresponding to Embodiment 2 or Embodiment 1 and Embodiment 2 The rivet pick-and-place mechanism of the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com