A new type of automatic shearing machine

A shearing machine, automatic technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of time-consuming, equipment troublesome, manpower consumption, etc., saving manpower and production time, saving space Travel time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

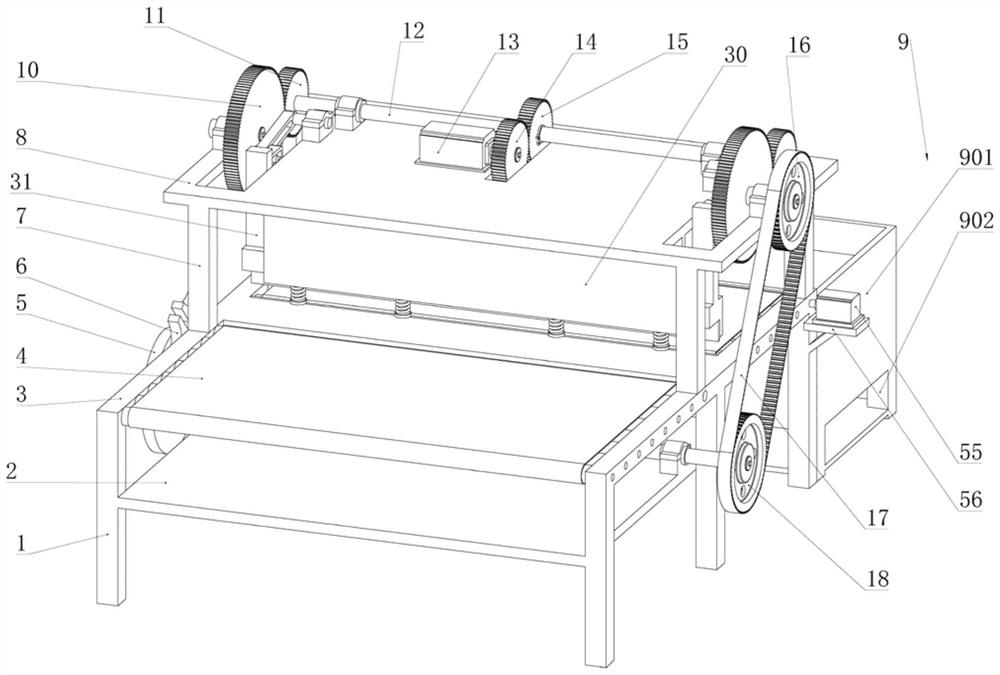

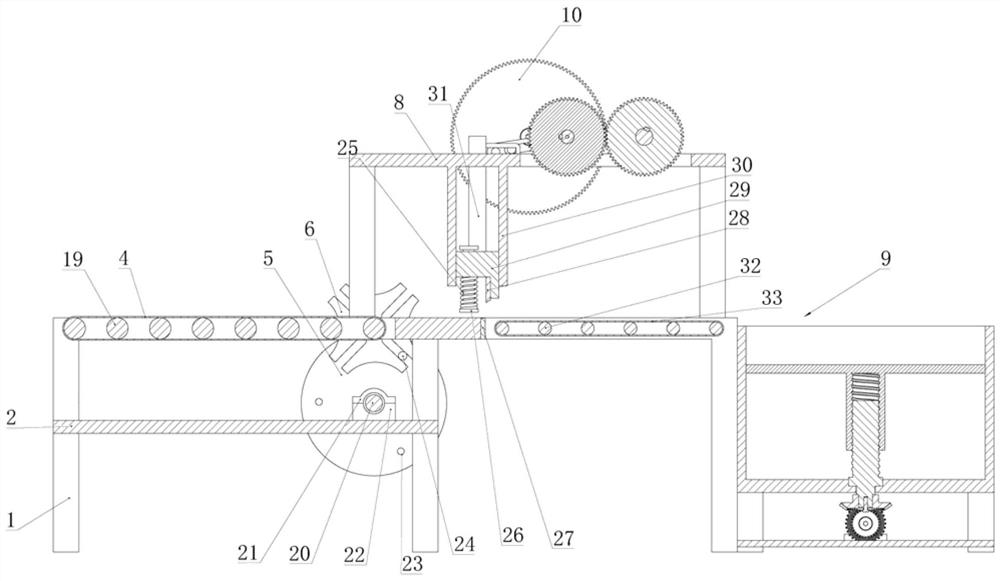

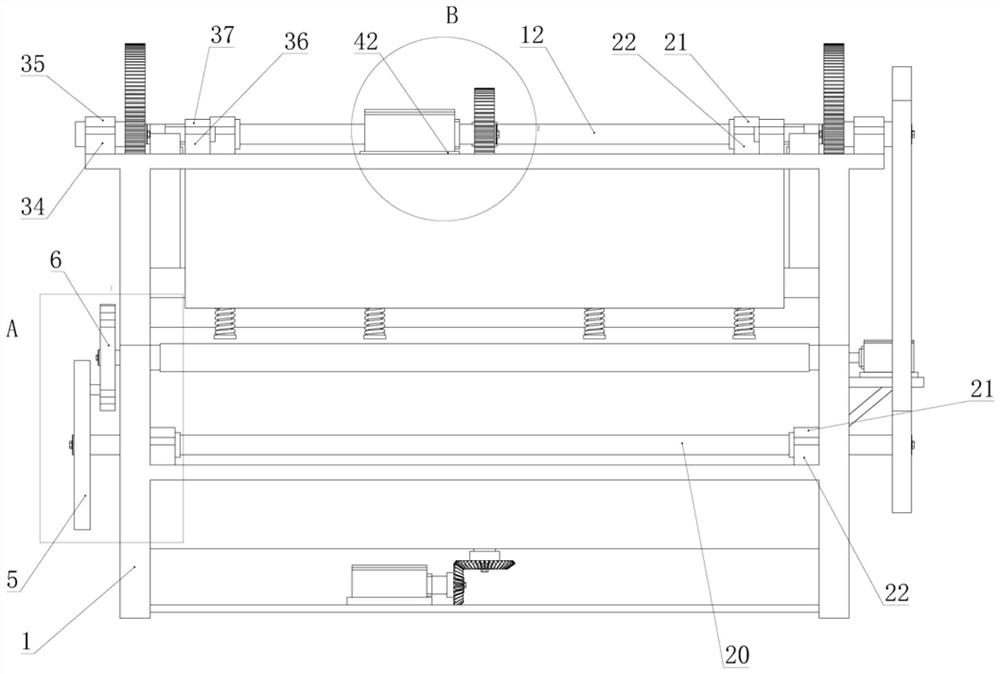

[0039] Attached below Figure 1-11 The present invention is described in detail below.

[0040] A new type of automatic shearing machine, see attached Figure 1-11 , comprising a lower column 1, a base 3, a lower cutter 27, and an upper cutter 28, the four corners of the lower end of the base 3 and the middle positions of the sides are welded with six lower columns 1 perpendicular to the plane of the base 3, the bottom of the base 3 And between the four lower columns 1 located at the front ends, a lower bottom plate 2 parallel to the plane of the base 3 is welded. Two lower bearing bushes 22 are respectively bolted on the left and right sides of the upper top surface of the lower bottom plate 2. The upper bearing bush 1 21 is bolt-connected at the position of the coaxial line above the lower bearing bush 1 22, and a freely rotatable small pulley rotating shaft 20 is installed at the coaxial position between the lower bearing bush 1 22 and the upper bearing bush 1 21. A small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com