Welding method and welding structure for internal stiffening plate and bottom plate support of steel pipe column

A welding method and welding structure technology, applied in welding equipment, building construction, metal processing equipment, etc., can solve problems such as poor connection stability, achieve the effect of increasing structural strength, improving connection stability, and simple welding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

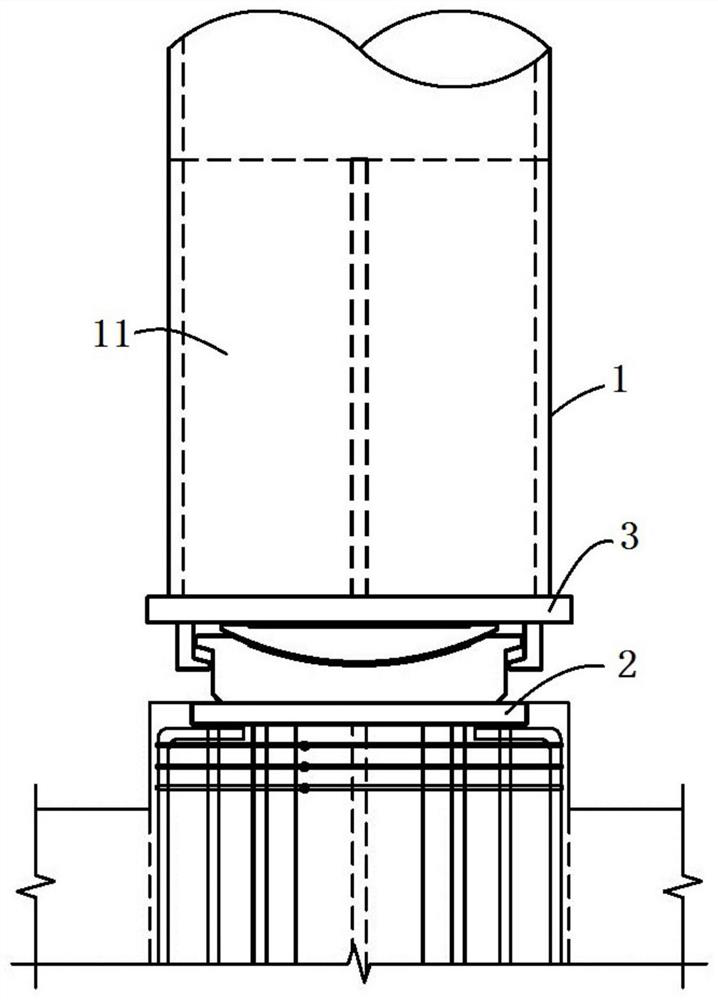

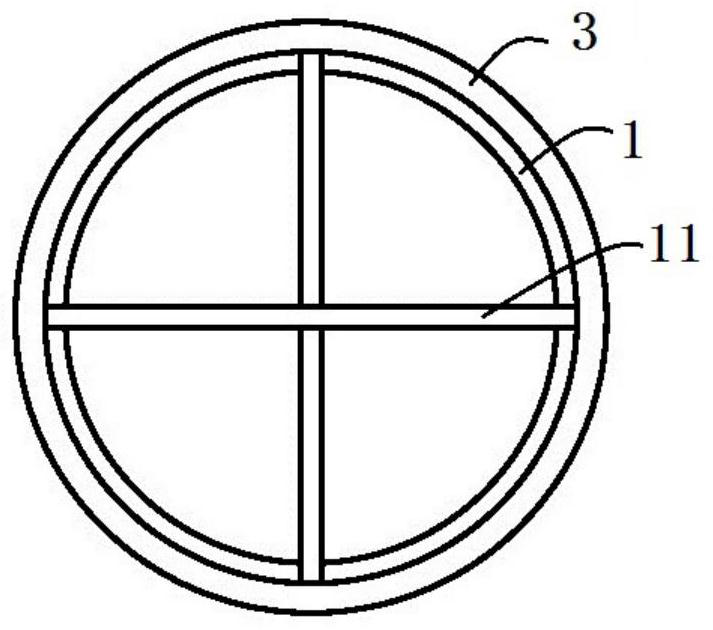

[0031] Such as figure 1 , figure 2 As shown, when the steel pipe column 1 is welded and fixed with the floor support 3 in the prior art, since the stiffening plate 11 is located inside the steel pipe column 1, the stiffening plate 11 cannot be fixed with the floor support 3, resulting in the steel pipe column 1 and the floor support The connection stability of seat 3 is poor.

[0032] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

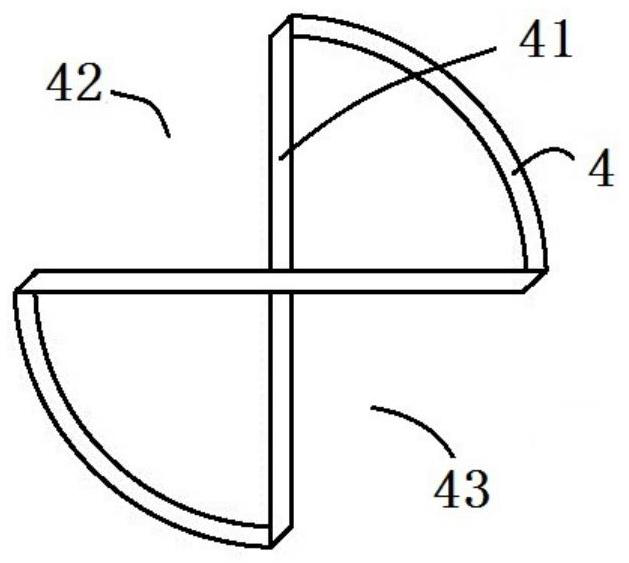

[0033] The present invention provides a steel pipe column internal stiffening plate and baseplate support welding structure, including: steel pipe column 4, stiffening plate 41 and two repair welding steel plates, one end of steel pipe column 4 is connected with baseplate support 5, steel pipe column 4 is connected to the baseplate One end connected to the support 5 is provided with an opposite gap, and the gap is set on the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com