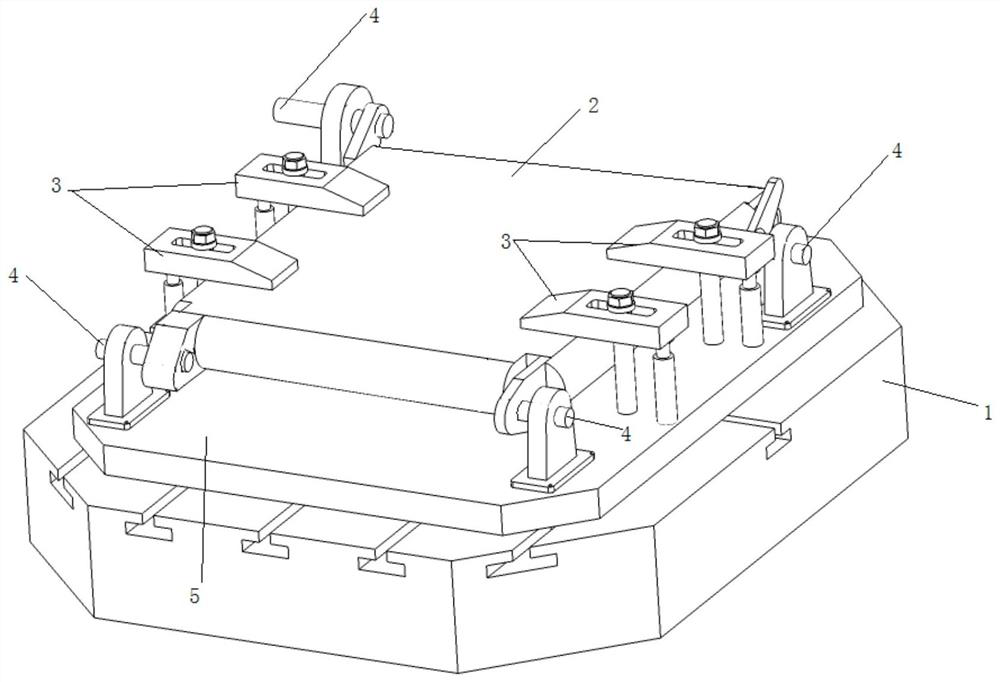

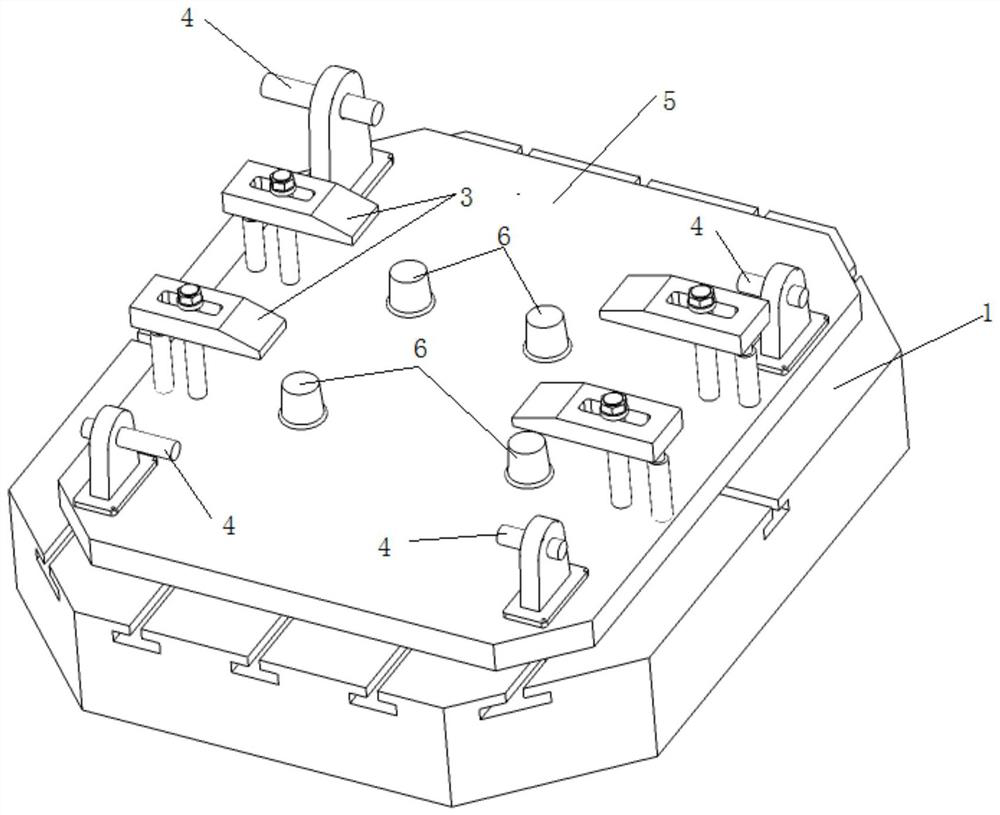

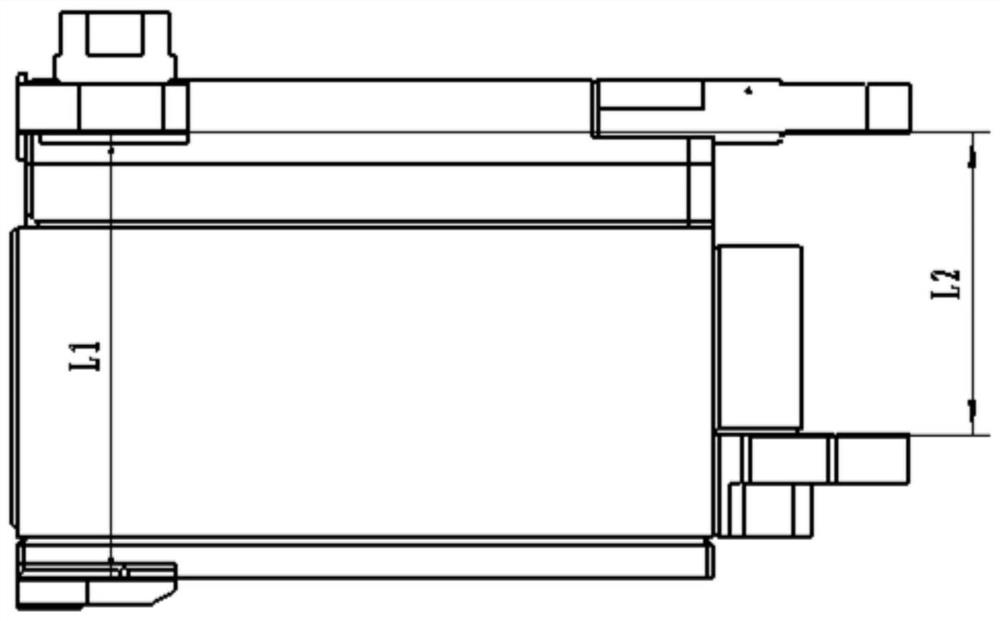

Special-shaped part machining method, fixture and fixture design method

A technology for parts processing and special-shaped body, applied in the fields of special-shaped body parts processing, fixture and fixture design, can solve the problems of slow operation process, inaccurate positioning, unstable processing position relationship, etc., to achieve controllable operation time and unified positioning elements , the effect of facilitating the organization of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is limited to following embodiment only, under the situation of not departing from the technical idea of the present invention, all Various modifications, replacements and changes made by technical knowledge and conventional means are included in the scope of the present invention.

[0052] Spatial multi-position control of special-shaped parts is a component structure problem often encountered in various processing fields, especially in the field of aerospace. Its process method directly affects the quality of products and production tasks, and also affects the assembly of host machines.

[0053]In the process of multi-position degree control of special-shaped parts in space, positioning is the key. The operator roughly clamps the workpiece to be processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com