Robot for overhauling inside of gasification equipment

A technology of gasification equipment and robots, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of no maintenance and survey robot equipment, achieve the effect of moderate size, simple operation, and prevent secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

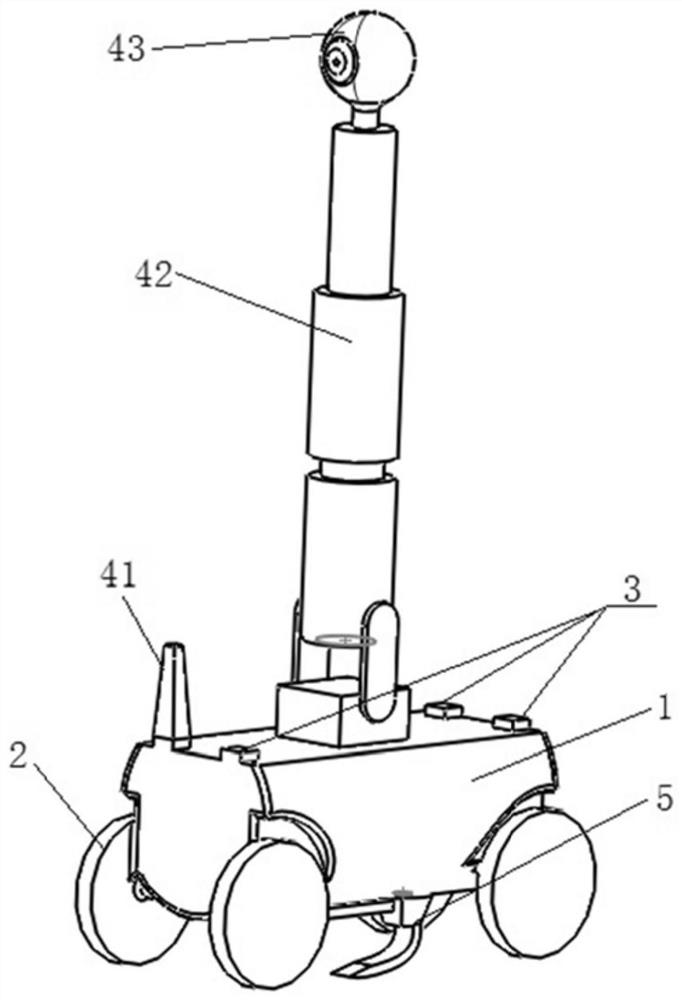

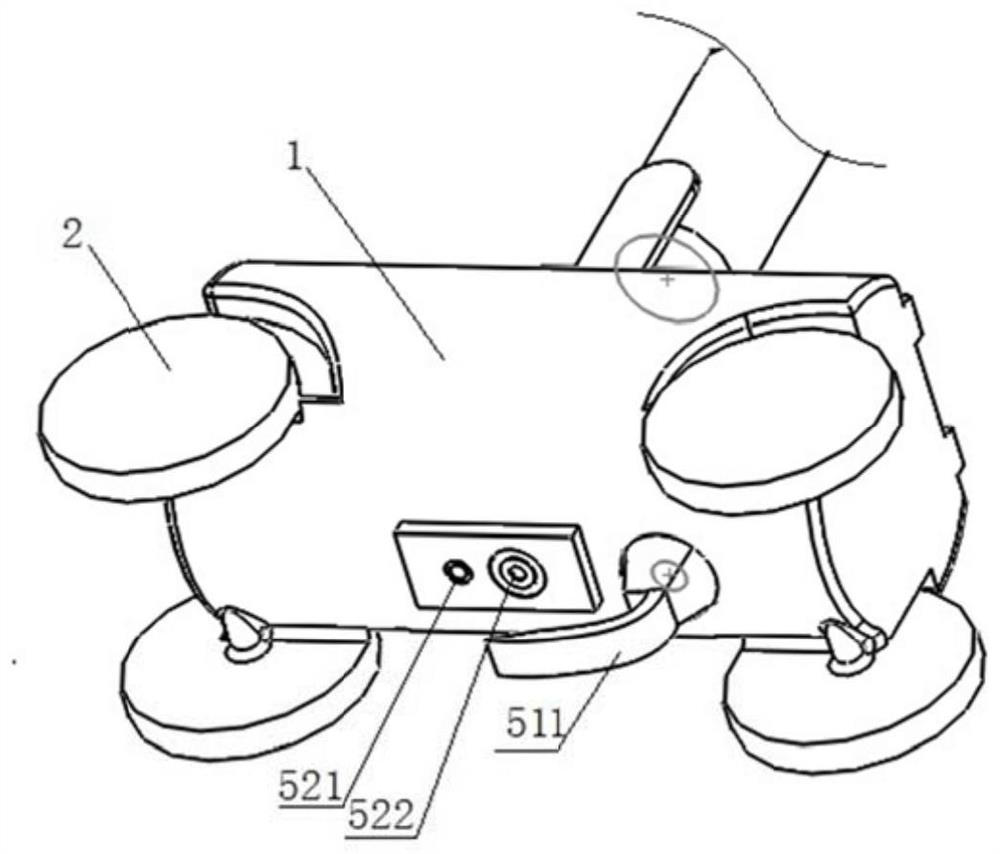

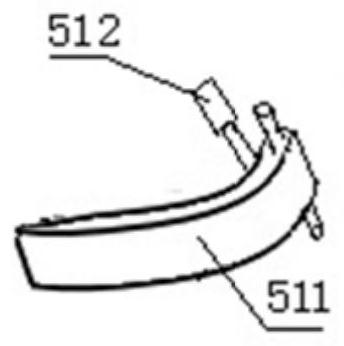

[0033] A maintenance robot inside the gasification equipment, such as Figure 1~4 As shown, it includes a car body 1 and a walking unit arranged on the car body 1, an ultrasonic detection unit, an image acquisition and transmission unit, and a scale detection unit, wherein the ultrasonic detection unit includes a plurality of ultrasonic sensors 3 for detecting the gasification equipment 6 The size of the inner space and the distribution of pipelines; the image acquisition and transmission unit is arranged on the top of the car body 1, and is composed of a wireless communicator 41, a telescopic arm 42 and a camera 43 arranged at the top of the telescopic arm 42, and the wireless communicator 41 is used to connect the camera 43 The collected image information is transmitted to the outside; the scale detection unit is set at the bottom of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com