Lifting raw material stirring device for concrete production

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, liquid ingredient supply device, etc., can solve the problems that concrete is easily adsorbed on its inner wall, affects the quality of concrete, and has a lot of concrete loss, so as to facilitate popularization and use, The effect of prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

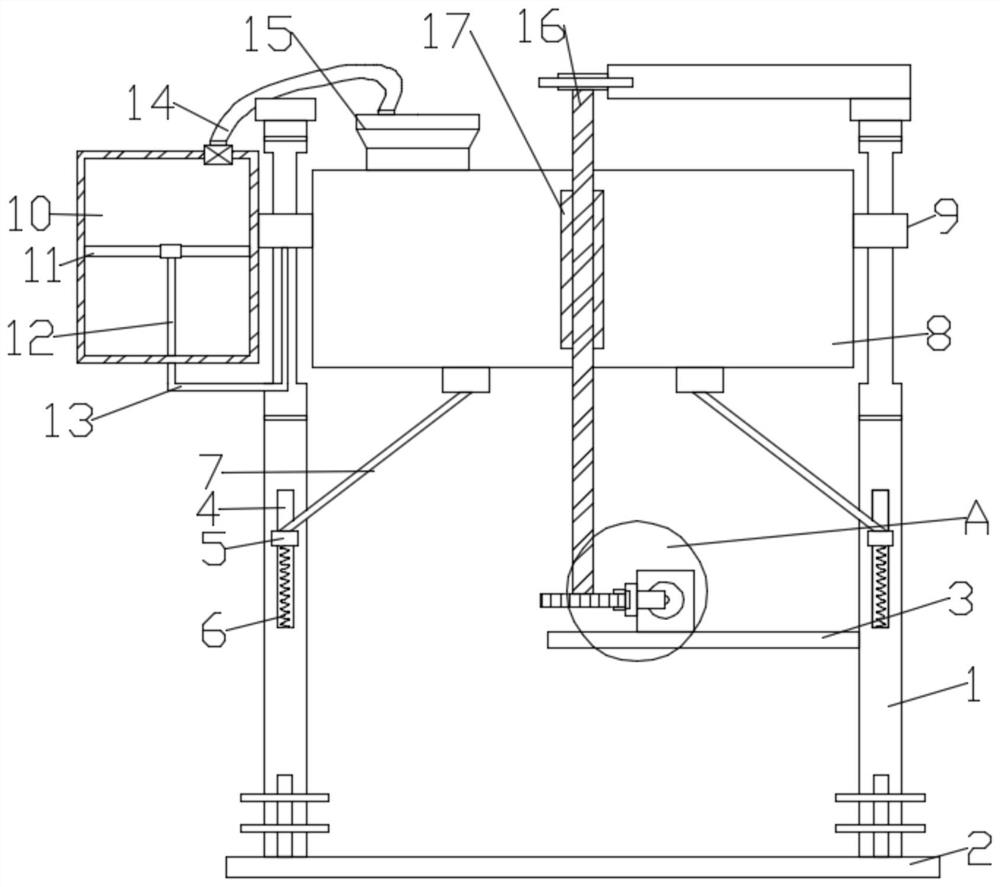

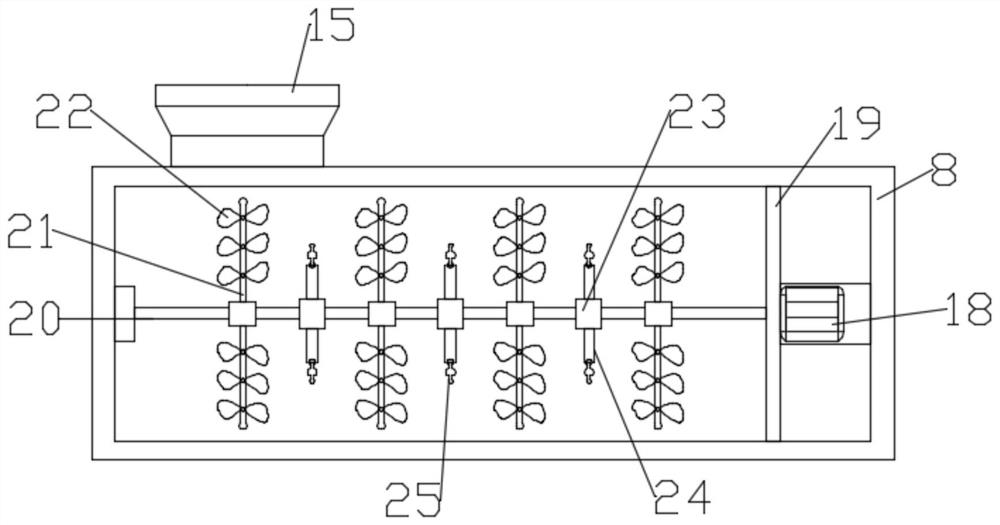

[0023] like figure 1 As shown, in the embodiment of the present invention, a lifting type concrete production raw material mixing device includes a support 1, a base 2 and a mixing chamber 8, and the upper part of the base 2 is symmetrically provided with two supports 1, and between the supports 1 is a mixing chamber. Stirring chamber 8 for raw materials, mixing mechanism is provided in stirring chamber 8, and feeding port 15 is provided on the upper surface of stirring chamber 8, mixing mechanism includes stirring component and anti-clogging component, and driving mechanism mounting seat 3 is fixedly installed on bracket 1, The driving mechanism mounting seat 3 is provided with a driving mechanism, the driving mechanism is connected with a lifting mechanism, and the lifting mechanism is connected with the stirring chamber 8;

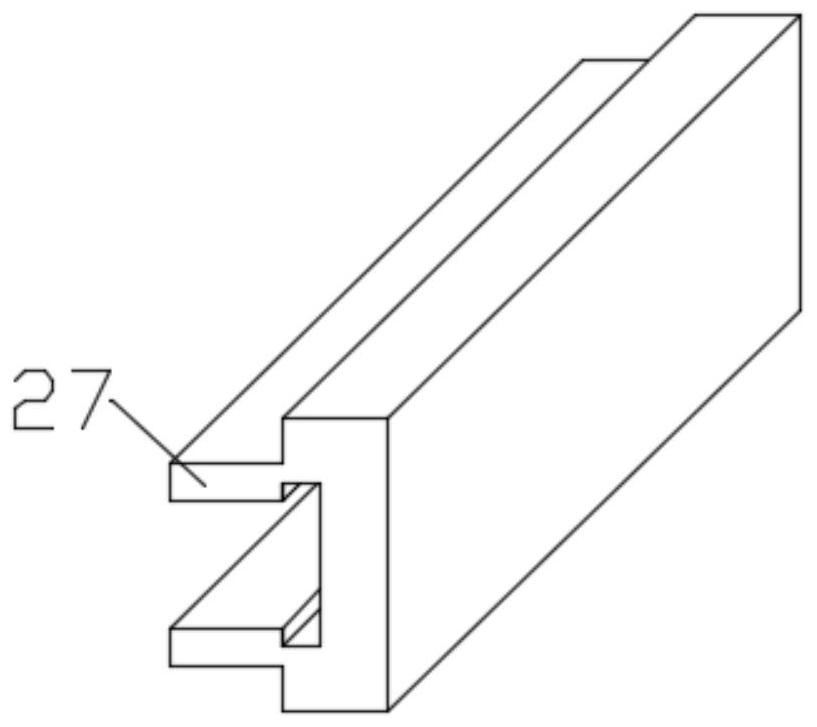

[0024] like Figure 3-4 As shown, the drive mechanism includes a hydraulic cylinder 26 and a horizontal rack 27, the hydraulic cylinder 26 is fixedly ...

Embodiment 2

[0033] like figure 1 As shown, in the embodiment of the present invention, a lifting type concrete production raw material mixing device includes a support 1, a base 2 and a mixing chamber 8, and the upper part of the base 2 is symmetrically provided with two supports 1, and between the supports 1 is a mixing chamber. Stirring chamber 8 for raw materials, mixing mechanism is provided in stirring chamber 8, and feeding port 15 is provided on the upper surface of stirring chamber 8, mixing mechanism includes stirring component and anti-clogging component, and driving mechanism mounting seat 3 is fixedly installed on bracket 1, The driving mechanism mounting seat 3 is provided with a driving mechanism, the driving mechanism is connected with a lifting mechanism, and the lifting mechanism is connected with the stirring chamber 8;

[0034] like Figure 3-4 As shown, the driving mechanism includes a hydraulic cylinder 26 and a horizontal rack 27, the hydraulic cylinder 26 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com