Method for preparing substantially spherical reaction compound of sulfur-containing silane and carbon black and product prepared by method

A sulfur-containing silane and compound technology, which is applied in the field of silane coupling agents, can solve the problems of reducing the amount of condensation reaction between sulfur-containing silane and carbon black, destroying the particle structure of carbon black aggregates, and the adverse effects of components and structures, so as to save The investment cost, the main equipment is simple, and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

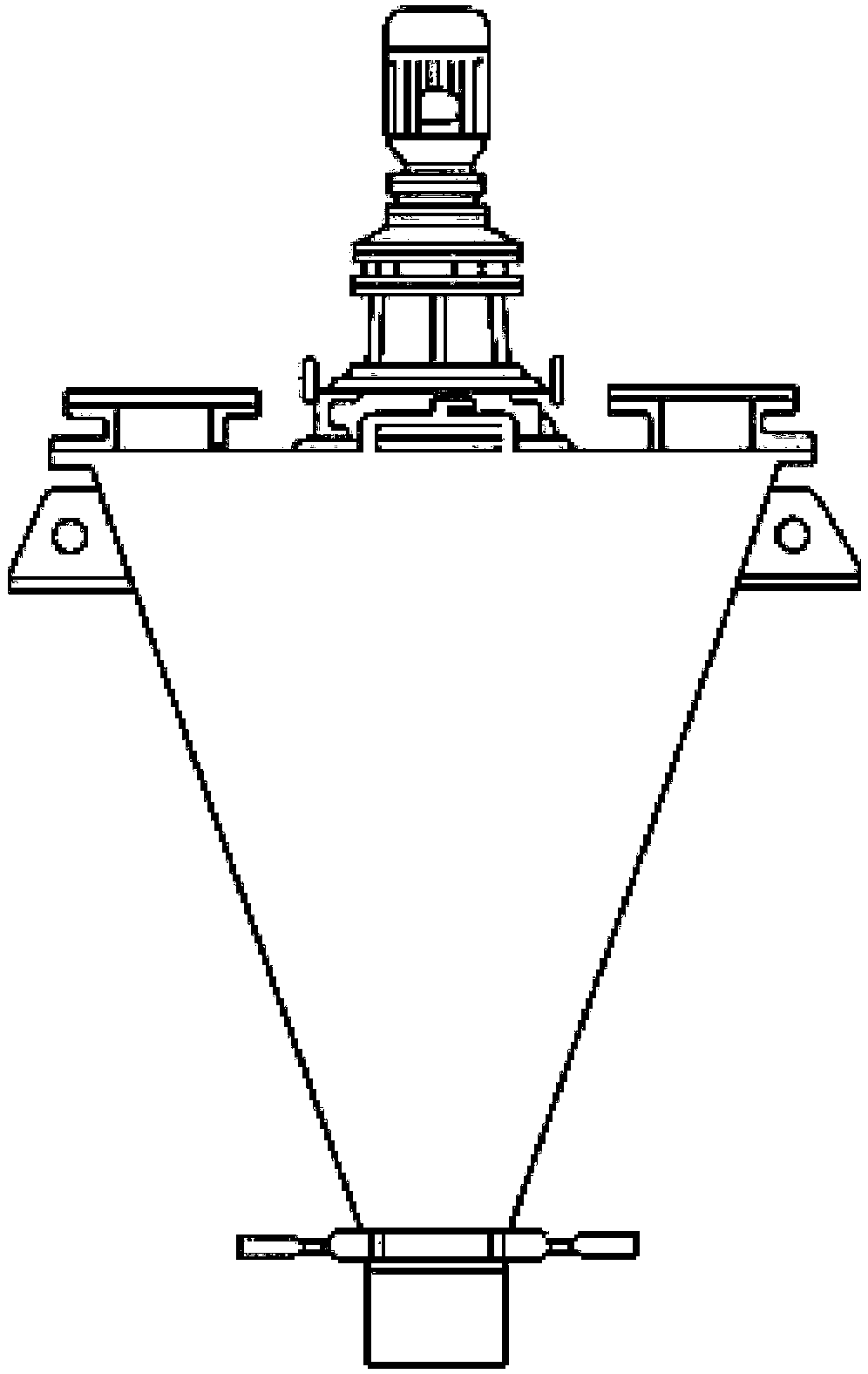

[0048] Turn on the stirring of the conical single-screw reaction mixer with a volume of 1000L, put 300kg of carbon black N330 into the conical single-screw mixer, adjust the stirring speed to 8 rpm, and stir for 10 minutes; then evenly drop double ‐[3‐(triethoxysilicon)‐propyl]‐disulfide silane coupling agent 400kg, dropwise in 23 to 25 minutes, continue to stir for 5 minutes, then stop stirring, at this time the temperature of the material is 43 °C, Turn it on to cool down and let it stand for 2.5 hours; then turn on the stirring and put in 100kg of carbon black N330, the stirring speed is controlled at a stirring speed of 2 rpm and mixed for 10 minutes to form a reaction premix crude product of about 800kg.

[0049] Continue to control the stirring speed of the mixer at 2 revolutions / min. After the mixer is evacuated to above -0.096MPa, then steam the jacket to raise the temperature. When the temperature of the material reaches 86-90°C, keep stirring and reacting under vacuum...

Embodiment 2

[0052] Turn on the stirring of the conical single-screw reaction mixer with a volume of 1000L, put 300kg of carbon black N330 into the conical single-screw mixer, adjust the stirring speed to 6 rpm and stir for 8 minutes; then evenly add double- [3‐(triethoxysilicon)‐propyl]‐tetrasulfide compound silane coupling agent 400kg, dropwise added in 23~25 minutes, continued to stir for 5min, then stopped stirring, at this moment, the material temperature was 36°C, Turn it on to lower the temperature and let it stand for 2.5 hours; then turn on the stirring and put in 100kg of carbon black N330, control the speed at 2 rpm and stir and mix for 10 minutes to form a reaction premix of about 800kg.

[0053] Continue to control the stirring speed of the mixer at 2 rpm. After vacuuming the mixer to above -0.096MPa, then steam the jacket to raise the temperature. When the temperature of the material reaches 90-94°C, keep stirring and reacting under vacuum for 20 hours. , reclaim the extracte...

Embodiment 3

[0057]Turn on the stirring of the conical single-screw reaction mixer with a volume of 1000L, put 300kg of carbon black N330 into the conical single-screw mixer, adjust the stirring speed to 8 rpm and stir for 10 minutes; [3-(triethoxysilicon)-propyl]-tetrasulfide compound silane coupling agent 400kg, dropwise in 23~25 minutes, continue to stir for 5min, stop stirring again, this moment material temperature is 43 ℃, Turn it on to lower the temperature and leave it for 2.5 hours; then add 100kg of carbon black N330, control the speed at 2 rpm and stir and mix for 10 minutes to form 800kg of crude mixture.

[0058] Continue to control the stirring speed of the mixer at 2 rpm. After vacuuming the mixer to above -0.096MPa, then steam the jacket to raise the temperature. When the temperature of the material reaches 90-94°C, keep stirring and reacting under vacuum for 20 hours. , reclaim the extracted ethanol by cryogenic condensing device; then stop the vacuum, stir and cool down u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com