Flue gas mixing element and flue gas denitration system using flue gas mixing element

A technology of flue gas mixing and components, which is applied in the field of flue gas purification, can solve the problems of unsatisfactory dispersion effect and achieve a favorable mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

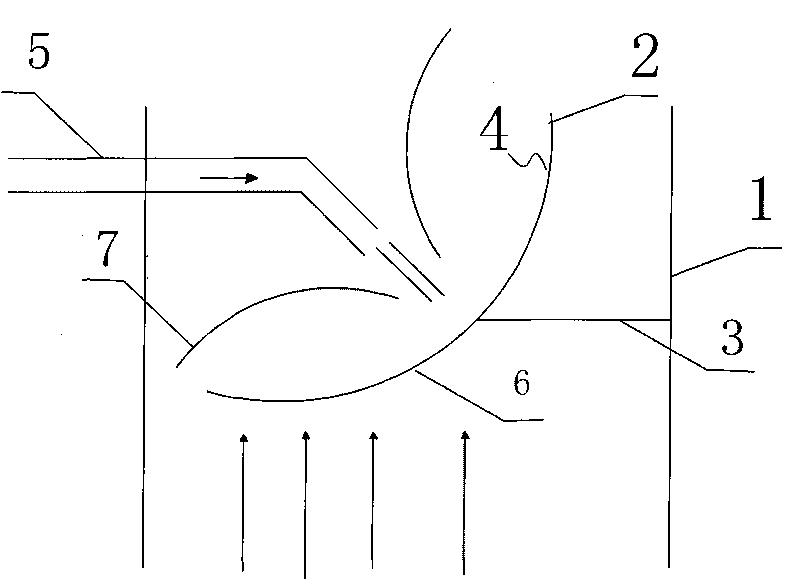

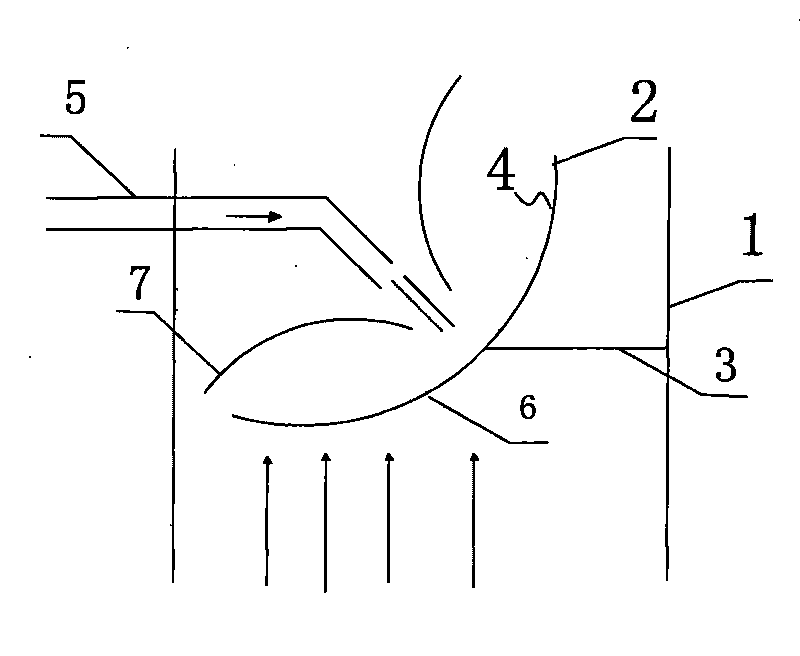

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0015] see figure 1 A mixing element 2 is set in the pipe 1 of the flue gas and reducing gas mixing part of the flue gas denitrification system, and the mixing element 2 is fixed on the inner wall of the pipe 1 through a support beam 3. The mixing element 2 is arc-shaped and placed obliquely In the pipeline 1, the backflow surface 4 of the mixing element 2 is concave and is opposite to the nozzle of the reducing agent nozzle 5, the backflow surface 4 of the mixing element 2 is not in contact with the nozzle of the reducing agent nozzle 5, and the flow direction of the mixing element 2 The surface 6 is convex and is opposite to the flow direction of the flue gas. In this way, when the reducing agent is sprayed onto the backflow surface 4 of the mixing element 2, it will evenly diffuse into a thin gas film 7; at the same time, when the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com