Selective segmented well cementing technology of double-target layer coal bed gas well and well structure

A coalbed methane well and wellbore structure technology, applied to wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve problems such as difficulty in lowering, difficult liquid level, low efficiency, etc., and achieve cost savings, The effect of reducing reservoir contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

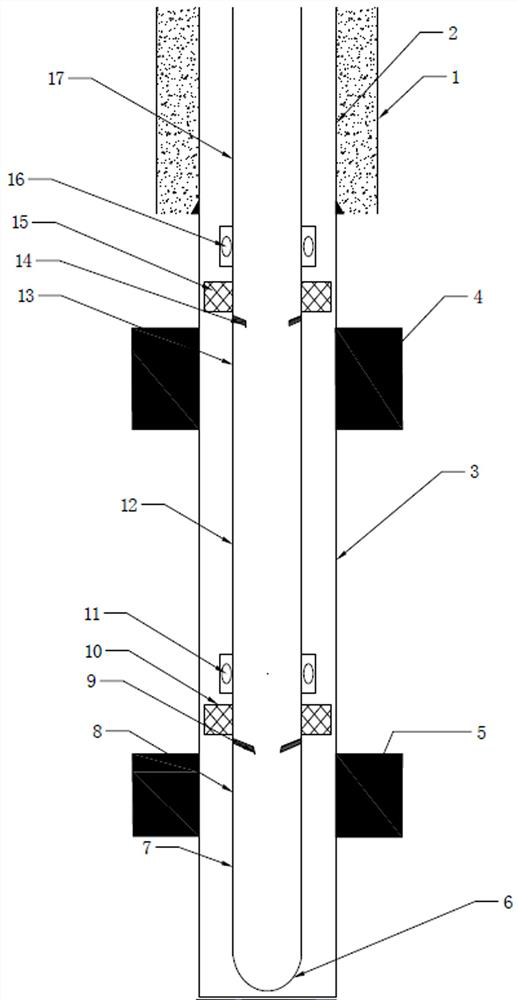

[0024] ① For the first hole drilling, a 311.15mm drill bit was used to drill 10-20 meters into the bedrock to form a drilling hole 1. J55φ244.50mm first surface casing 2 was inserted to cement the well and wait for solidification to prevent collapse and prevention. Leakage effect

[0025] ②The second hole was drilled with a 215.9mm drill bit, through the upper and lower target coal seams and drilled to the lower target coal seam 5 and 50m below the bottom plate to complete the drilling, perform final hole logging, and arrange the entry material position according to the logging depth data. Such as figure 1 , From the bottom of the borehole upwards are casing shoes 6, lower casing 7, lower coal section sliding sleeve 8, lower ball seat 9, lower packer 10, lower classification hoop 11, middle casing 12, upper coal section Sliding sleeve 13, upper ball seat 14, upper packer 15, upper grading hoop 16, upper casing 17;

[0026] ③Calculate the amount of cement in each section of annulus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com