Predictive maintenance system and method for vacuum pump and automatic vacuum pump purchasing system

A maintenance system and vacuum pump technology, applied in forecasting, pump testing, pump control, etc., can solve problems such as difficulty in formulating maintenance, replacement plans, large differences in vacuum pump status, and increased capital occupancy, avoiding scrap of raw materials and better results , The effect of reducing the occupancy rate of spare parts funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

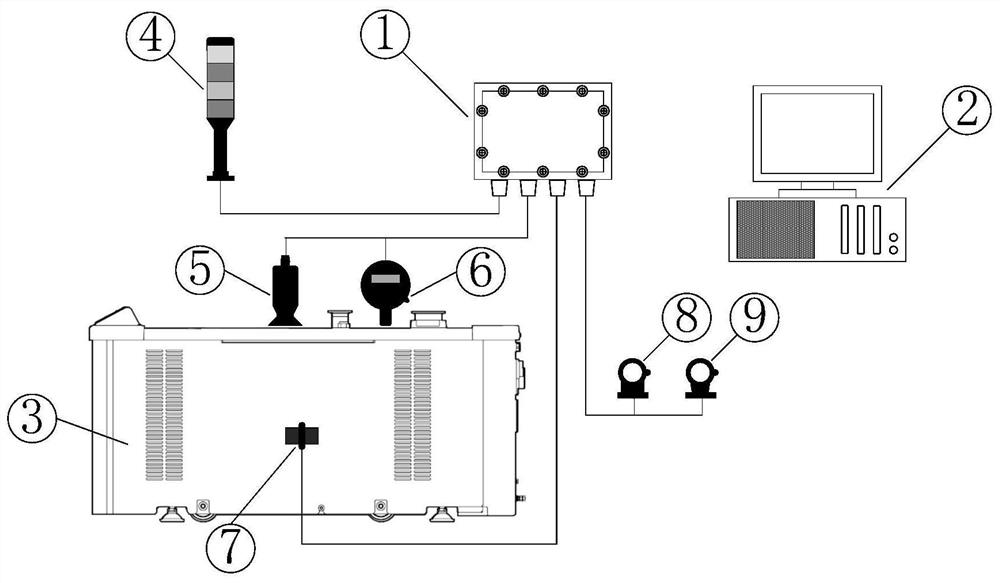

[0053] Please refer to figure 1 , figure 1 It is a schematic diagram of the composition of the predictive maintenance system of the vacuum pump, including the embedded monitoring terminal 1, the data center server 2, the vibration sensor 5, the pressure sensor 6, the temperature sensor 7, the voltage transformer 8, and the current sensor 9. The specific scheme of this system is as follows:

[0054] The vibration sensor 5 adopts a magnetic suction method and is installed at the impeller position of the intelligent vacuum pump 3 to monitor the vibration intensity. The pressure sensor 6 adopts a threaded interface and is installed on the pressure measuring port of the intelligent vacuum pump 3 to monitor the vacuum negative pressure. The temperature sensor 7 is pasted and installed on the side of the intelligent vacuum pump 3, corresponding to the position of the motor, to monitor the temperature of the pump body. The live wire of the power cord of the intelligent vacuum pump 3 p...

Embodiment 2

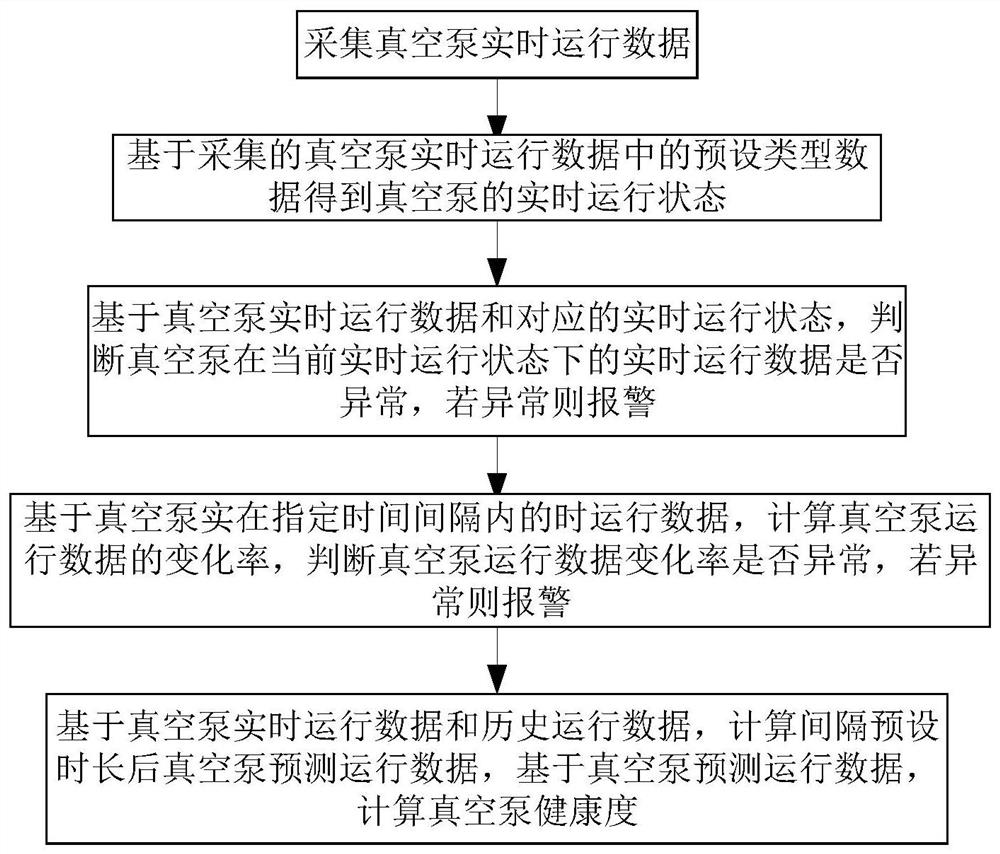

[0070] Please refer to image 3 , image 3 As a schematic flow chart of a predictive maintenance method for a vacuum pump, the second embodiment of the present invention provides a predictive maintenance method for a vacuum pump, and the method includes:

[0071] Collect real-time operating data of the vacuum pump;

[0072] Obtain the real-time operation status of the vacuum pump based on the preset type data in the collected real-time operation data of the vacuum pump;

[0073] Based on the real-time operation data of the vacuum pump and the corresponding real-time operation status, judge whether the real-time operation data of the vacuum pump in the current real-time operation status is abnormal, and alarm if abnormal;

[0074] Based on the real-time operating data of the vacuum pump within the specified time interval, calculate the rate of change of the vacuum pump operating data, determine whether the rate of change of the vacuum pump operating data is abnormal, and alarm if abnorm...

Embodiment 3

[0077] Please refer to Figure 4 , Figure 4 As a schematic diagram of the composition of an automatic procurement device for a vacuum pump, the third embodiment of the present invention provides an automatic procurement system for a vacuum pump, and the system includes:

[0078] Predictive maintenance module, the predictive maintenance module is the predictive maintenance system described in the first embodiment, based on the predictive maintenance system to generate the health of vacuum pumps, and based on the health of all vacuum pumps, to generate the purchase time and quantity of vacuum pumps;

[0079] Purchasing module is used to generate purchase orders for the purchase time and quantity of vacuum pumps, and automatically purchase vacuum pumps based on the purchase orders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com