Novel header type heat storage radiant plate type indoor heat exchanger for winter and summer

An indoor heat exchanger and heat radiant panel technology, applied in indirect heat exchangers, heat exchanger types, and central heating, can solve the problems of easy to produce blowing sensation, reduce thermal comfort, affect indoor temperature, etc., to reduce the system The effect of energy loss and transportation energy consumption, reducing investment cost and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

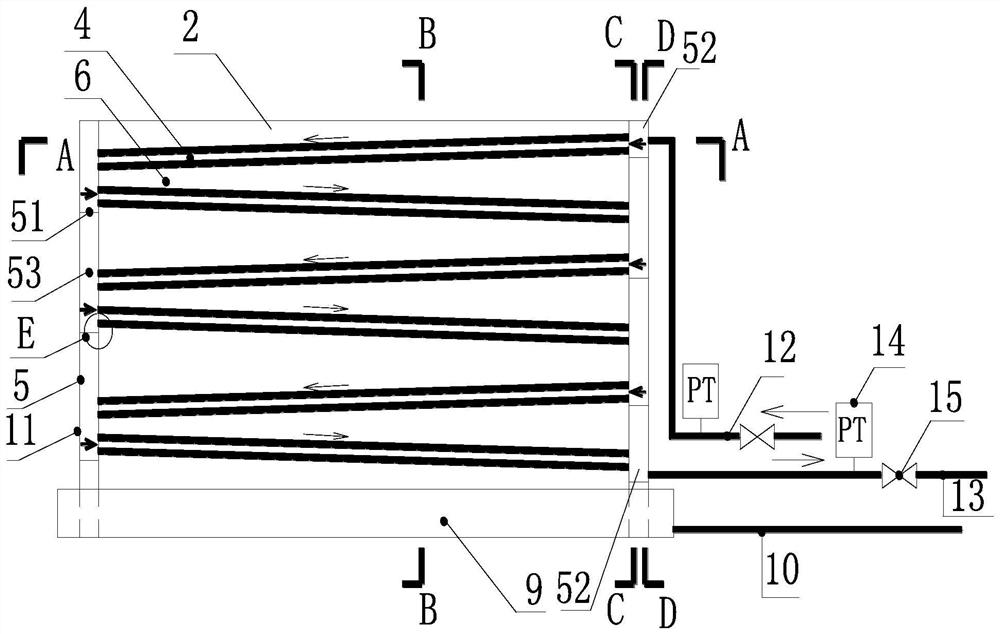

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

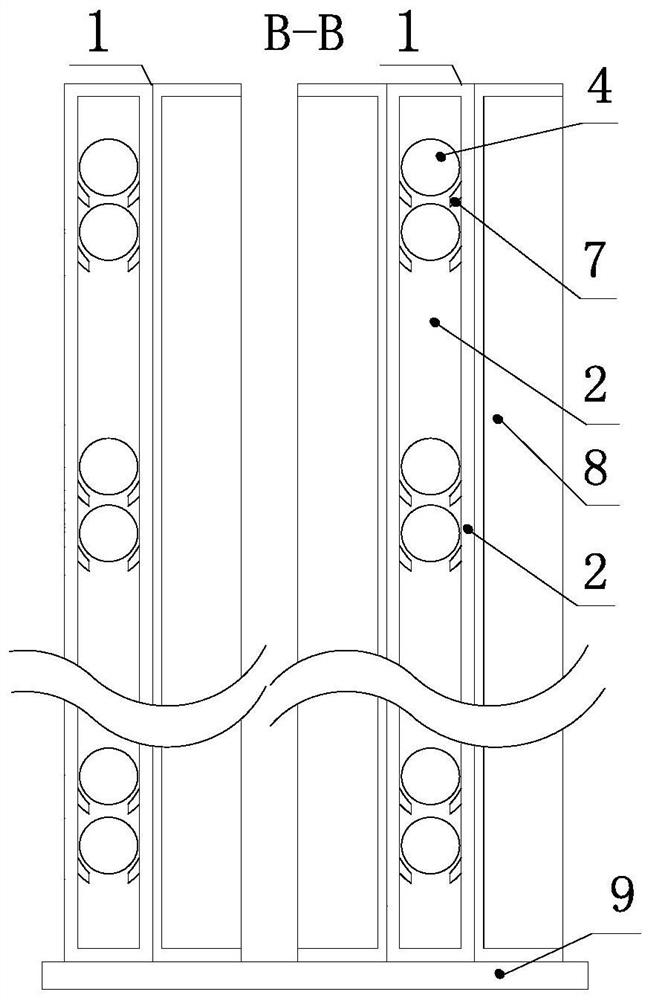

[0030] The present invention proposes a new type of header-type thermal storage radiant plate indoor heat exchanger for both winter and summer, which includes a plurality of radiant plate heat exchange fins 1 arranged side by side, such as Figure 2 to Figure 5 as shown,

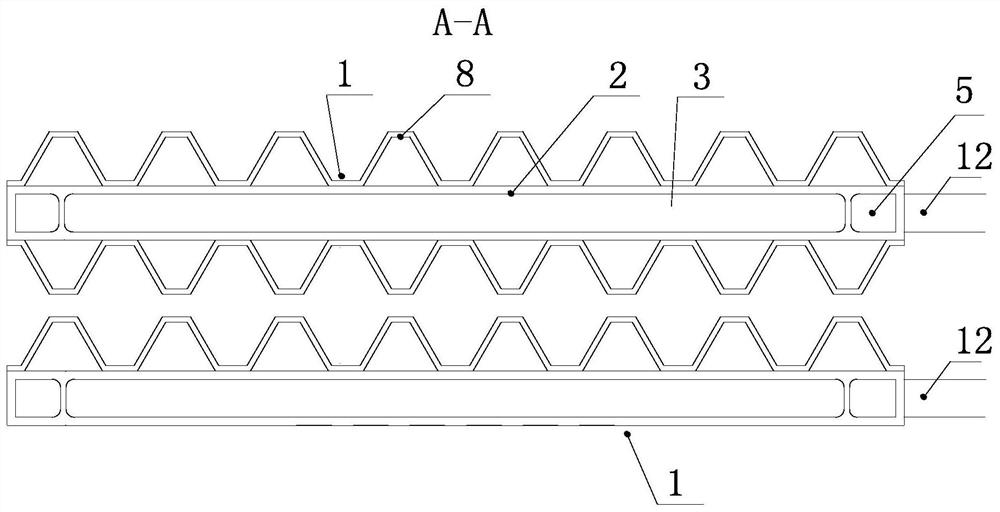

[0031] Such as figure 1 As shown, the radiant plate heat exchange fin 1 includes a radiant plate interlayer 3 composed of two front and rear galvanized steel sheets 2, and the radiant plate interlayer 3 is provided with n rows of heat exchange tube bundles 4 from top to bottom, n= 3 to 20; among all heat exchange tube bundles, the included angle between the heat exchange tube bundles in the odd rows and the horizontal direction is α, and the angle between the heat exchange tube bundles in the even rows and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com