Motor testing device and testing method

A technology for motor testing and the motor under test, applied in the direction of motor generator testing, measuring device casing, etc., can solve the problems of cumbersome test operation methods, inconvenient testing work, and many complicated steps, so as to protect less or no damage, Simple structure and simple test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

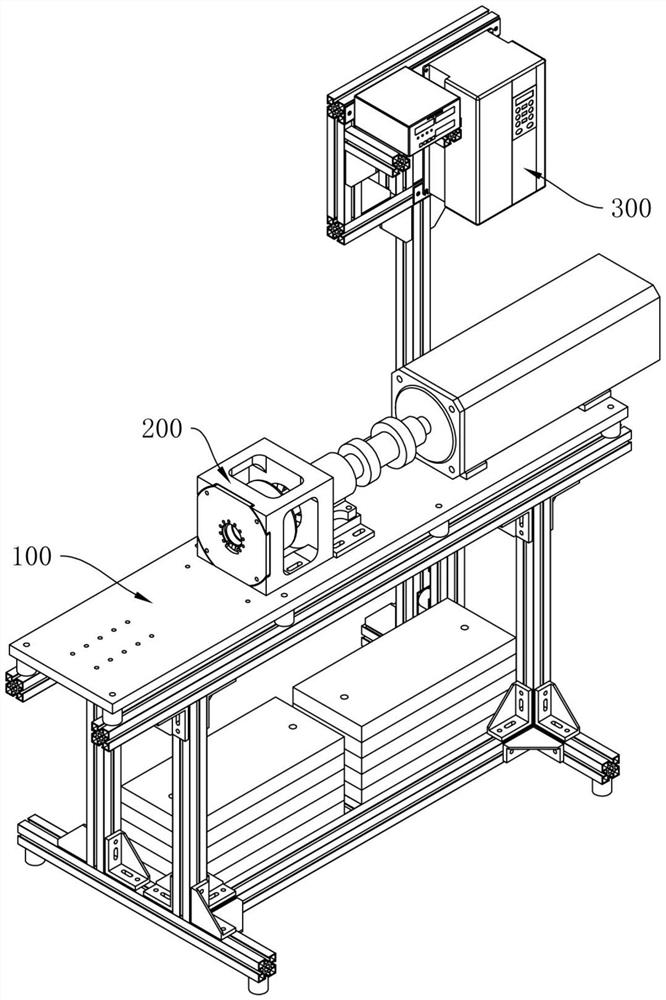

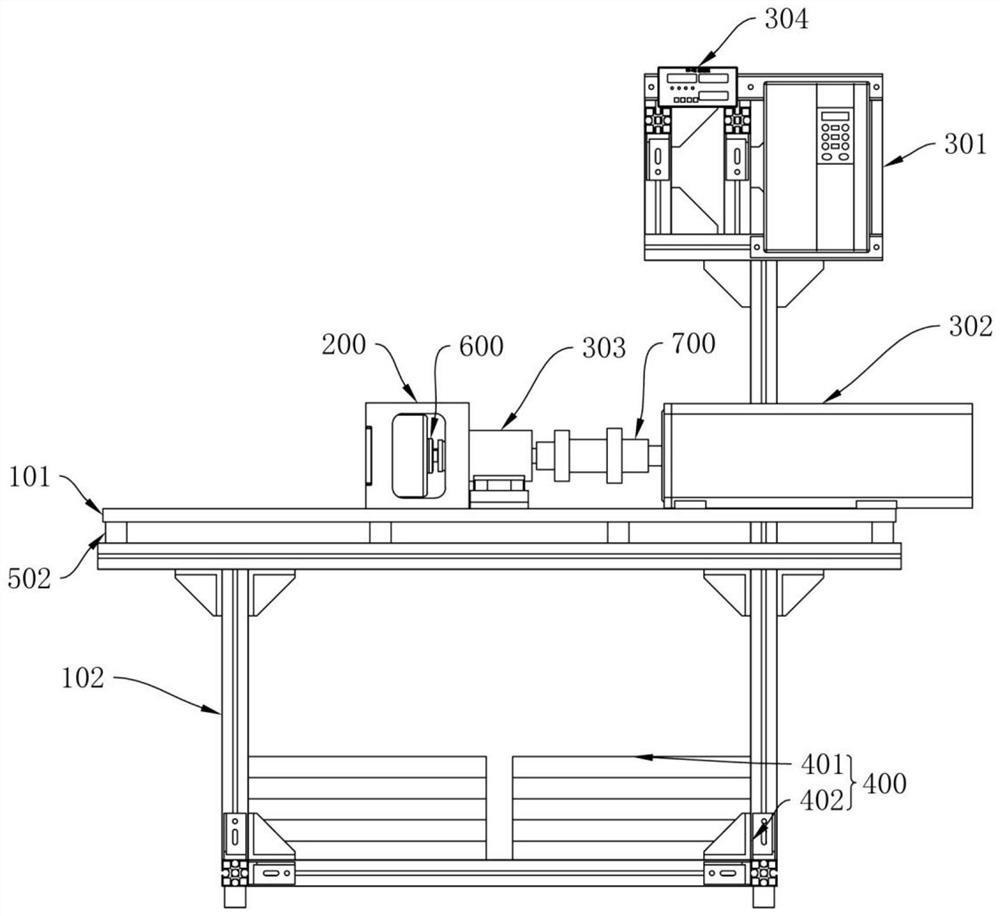

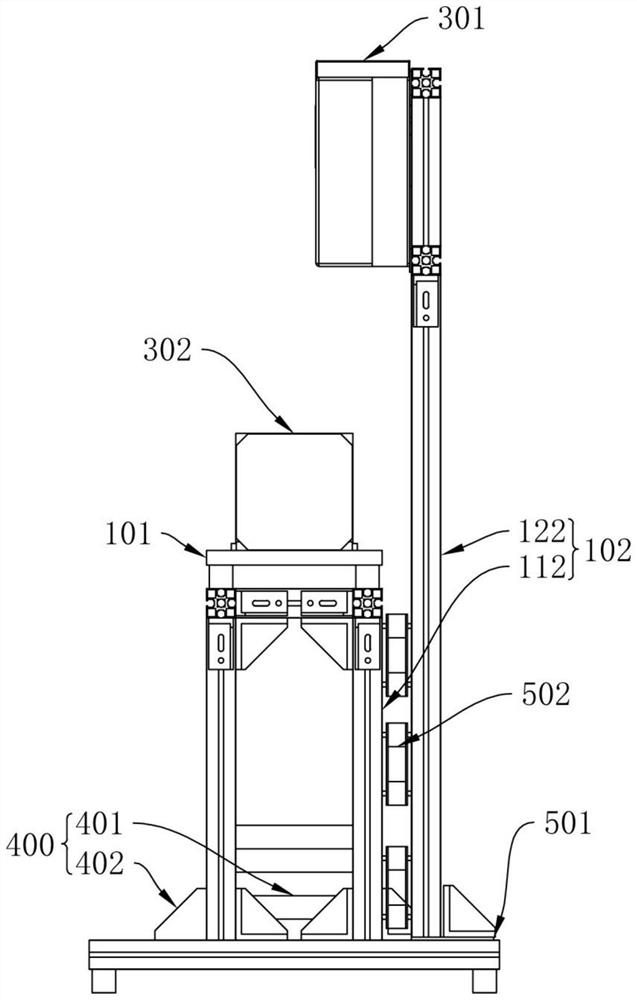

[0046] see Figure 1 to Figure 8 . A motor testing device described in this embodiment includes:

[0047] The base 100 is used to support the whole of the device, and the base 100 is used for the installation and connection of various components. In this embodiment, the base 100 is the outer frame of the support device as a whole, and the base 100 is used as a carrier. The connection and installation are all based on the base 100;

[0048] The first fixing assembly 200 is used for fixing the motor under test. The first fixing assembly 200 is arranged on the base 100. The first fixing assembly 200 has many different types. The size of the required first fixing assembly 200 is selected. In this embodiment, the first fixing assembly 200 has four types: a, b, c, and d. The a-type first fixing assembly can fix a large motor. The b-type first fixing component can fix large and medium-sized motors, the c-type first fixing component can fix medium-sized motors, and the d-type first...

Embodiment 2

[0059] see Figure 1 to Figure 8 . A motor testing method described in this embodiment uses the motor testing device described in Embodiment 1 for testing. Since the motor testing device has been described in detail in Embodiment 1, it will not be repeated in this embodiment. To repeat the same content, the motor test method includes the following steps:

[0060] Step 1: Fix the motor under test on the motor testing device through the first fixing component 200. Before performing this step, select a suitable first fixing component 200 according to the type and size of the motor, and then fix the motor under test;

[0061] Step 2: adjust the control unit 301, adjust the voltage and frequency of the output power supply, adjust the speed of the power unit 302, and drive the motor under test through the power unit 302;

[0062] Step 3: The detection unit 303 detects the motor under test, and converts the measured information into electrical signals and transmits them to the acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com