Method for starting up gas turbine engine of combined cycle power plant

A technology for gas turbines and power plants, which is used in engine starting, turbine/propulsion fuel control, engine functions, etc., and can solve problems such as reducing the life of key HRSG components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

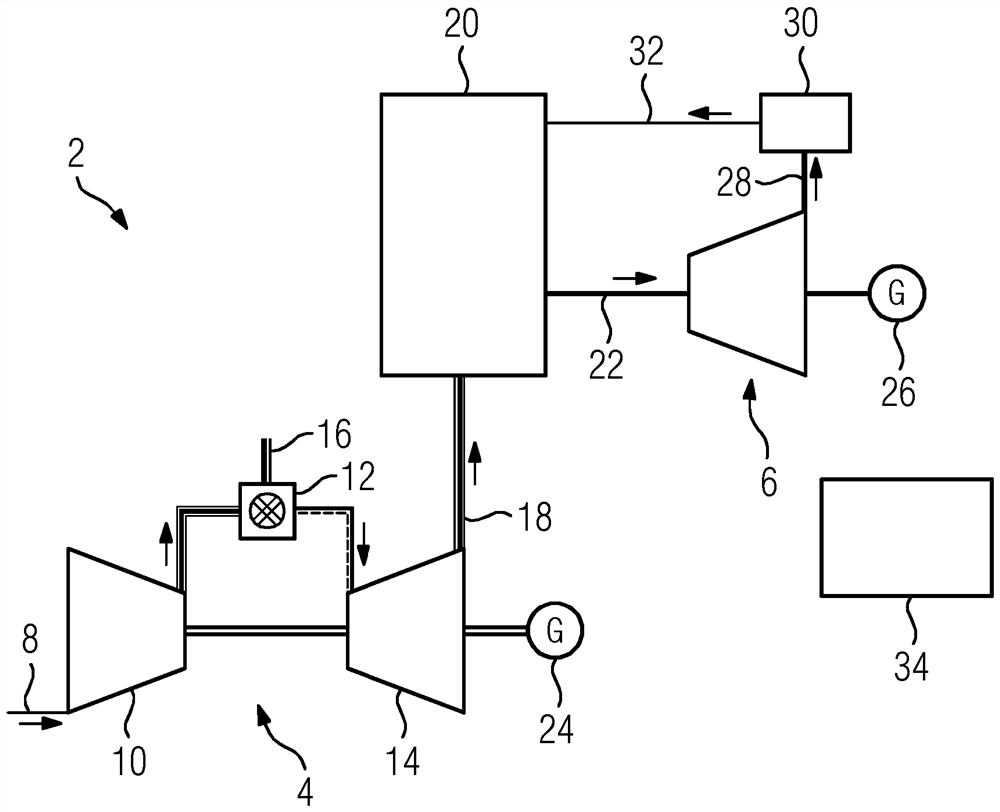

[0041] refer to figure 1 , shows an abstract schematic diagram of the combined cycle power plant 2 . In the figure, a gas turbine engine 4 and a steam turbine engine 6 are shown.

[0042] Gas turbine engine 1 includes an inlet 8 , a compressor 10 , a combustor 12 and a turbine 14 . Fuel 16 is supplied to combustor 12 as indicated by the arrow. The fluid exhausted by the turbine 14 is identified as exhaust fluid 18 .

[0043] Exhaust fluid 18 is provided to heat exchanger 20 , particularly a heat recovery steam generator (HRSG). In the HRSG 20 all heat recovered from the exhaust fluid 18 is converted into high pressure steam 22 which is used to drive the steam turbine engine 6 which converts the energy of the steam into mechanical energy which in turn is converted into electricity.

[0044] The gas turbine engine 4 drives a first generator 24 such that the mechanical load on the gas turbine engine 4 is converted to electrical power in the first generator 24 . The steam tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com