Coal cinder environment-friendly brick raw material crushing device

A technology of crushing raw materials and environmentally friendly bricks, which is applied in the direction of grain processing, etc., can solve the problems of insufficient centering of feed materials, inconvenient feed speed of cinders, and inability to meet the needs of non-production and use, and achieve the effect of facilitating sealing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

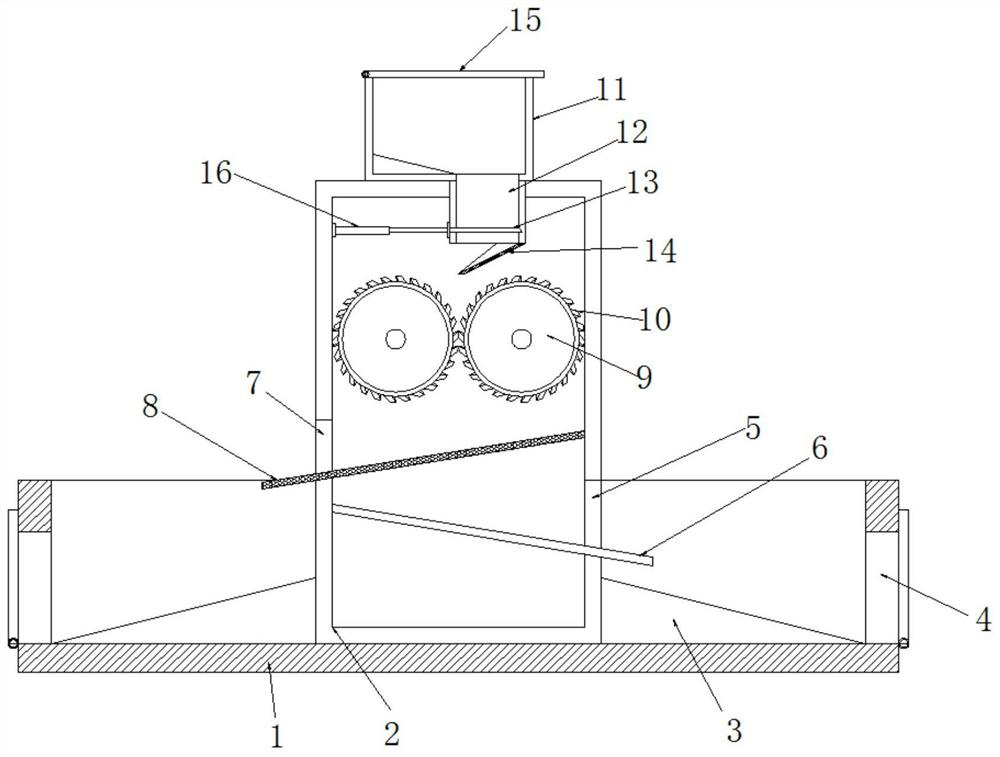

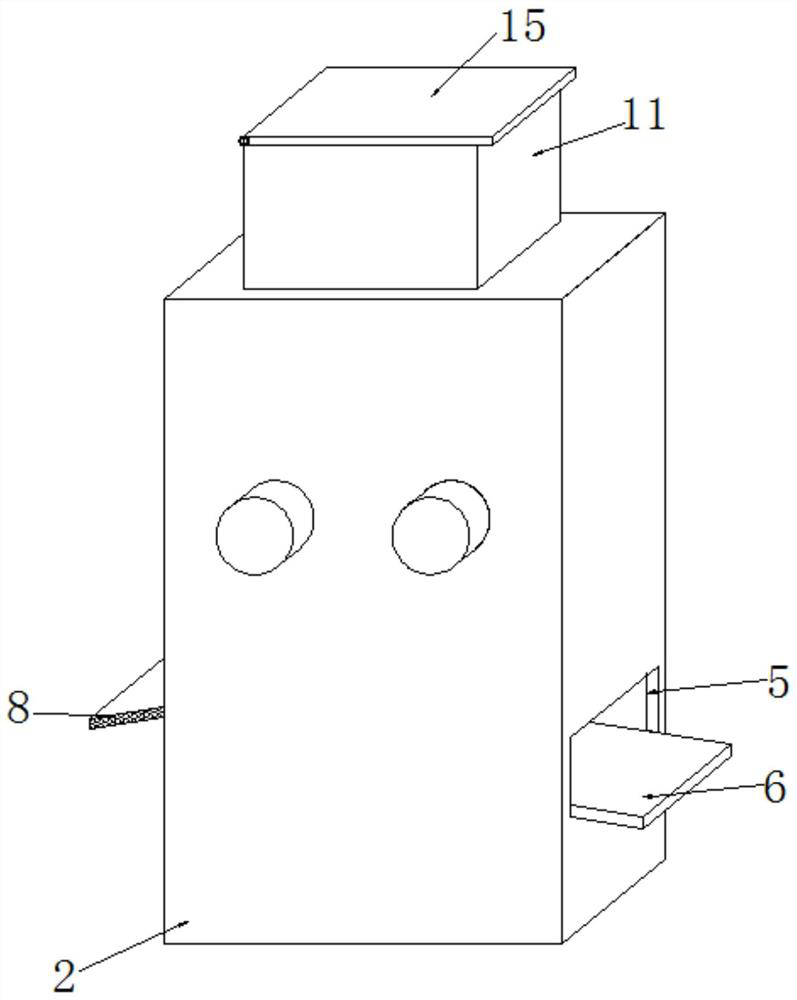

[0023] refer to figure 1 and figure 2 , a coal cinder environment-friendly brick raw material crushing device, comprising a collection box 1, a crushing box 2 is fixed at the center of the bottom inner wall of the collection box 1, and a feeding box 11 is fixed on the outer wall of the top of the crushing box 2, and a plug connector is fixed at the bottom of the feeding box 11 The feeding tube 12 in the pulverizing box 2 is movably inserted with a feeding mechanism, the outer wall of the bottom end of the feeding tube 12 is fixed with a sloping plate 14, and there are two relatively rotating pulverizing mechanisms installed in the pulverizing box 2. , one side of the crushing mechanism is connected with a motor, the outer wall on the left side of the crushing box 2 is provided with a discharge port 7, and an inclined filter screen 8 is fixed inside the discharge port 7, and a material guide mechanism is provided at the bottom of the right side of the crushing box 2 .

[002...

Embodiment 2

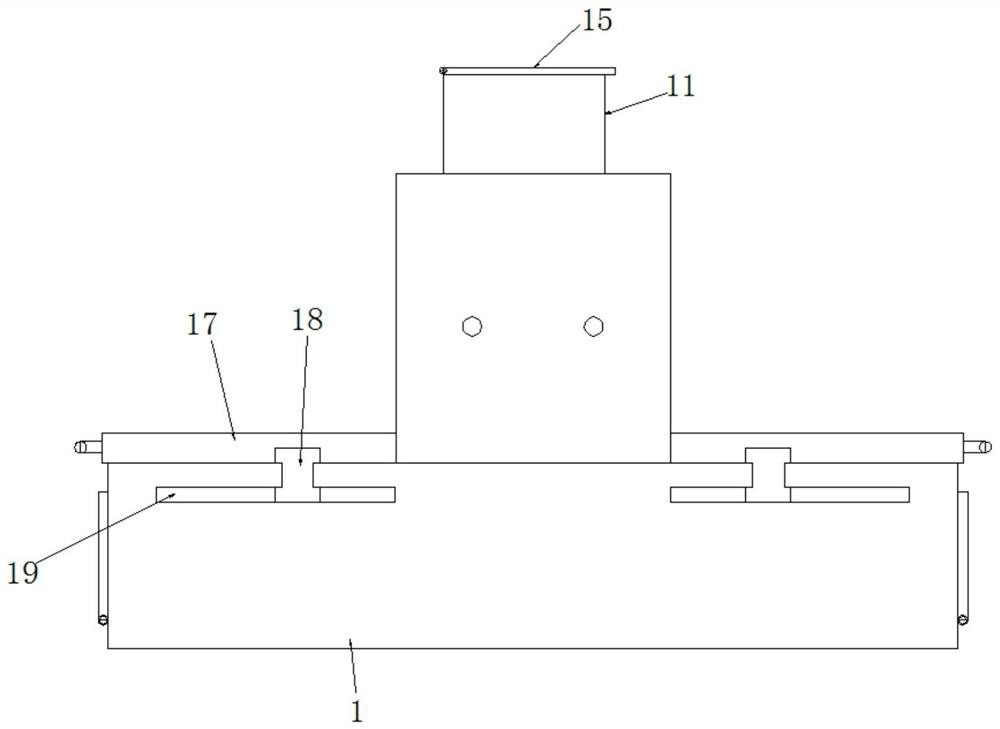

[0027] refer to image 3 , a coal cinder environment-friendly brick raw material crushing device, comprising a collection box 1, a crushing box 2 is fixed at the center of the bottom inner wall of the collection box 1, and a feeding box 11 is fixed on the outer wall of the top of the crushing box 2, and a plug connector is fixed at the bottom of the feeding box 11 The feeding tube 12 in the pulverizing box 2 is movably inserted with a feeding mechanism, the outer wall of the bottom end of the feeding tube 12 is fixed with a sloping plate 14, and there are two relatively rotating pulverizing mechanisms installed in the pulverizing box 2. , one side of the crushing mechanism is connected with a motor, the outer wall on the left side of the crushing box 2 is provided with a discharge port 7, and an inclined filter screen 8 is fixed inside the discharge port 7, and a material guide mechanism is provided at the bottom of the right side of the crushing box 2 .

[0028] The blanking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com