Grinding and polishing fixing fixture

A technology for fixing fixtures and clamping jaws, applied in grinding/polishing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of hand abrasion, uneven sample surface, inconvenient use, etc., and achieve convenient operation. , affordable, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

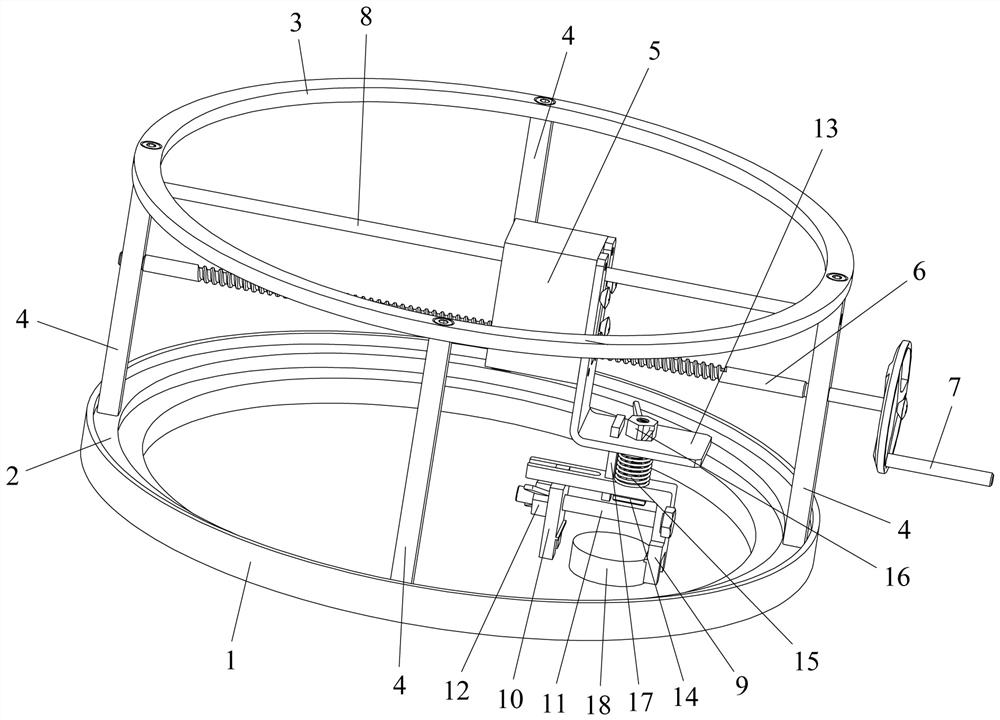

[0019] Example 1: The MP-2 metallographic sample grinding and polishing machine is an economical model that combines the pre-grinding and polishing operations of sample 18, and is an ideal equipment for small and medium-sized enterprises and laboratories to make sample 18. The simple grinding and polishing sample fixing fixture of the present invention is placed on this type of metallographic sample grinding and polishing machine, and is used to fix the sample 18 and load it on the grinding and polishing machine to grind and / or polish the sample 18.

[0020] as attached figure 1 As shown, a grinding and polishing fixture includes a base 1, a bracket, a slider 5, a translation mechanism and a clamping mechanism.

[0021] Base 1 is used to mount the entire fixture to the grinding / polishing disc of the grinder-polisher. The outer diameter of the grinding disc of the polishing machine is 230mm, and the outer diameter of the polishing disc is 203mm. Since the outer diameters of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com