Preparation method of nanoscale cobaltosic oxide

A nano-scale technology of cobalt tetroxide, which is applied in the field of nanomaterials, can solve the problems of difficult nanoparticles, easy agglomeration of cobalt tetroxide, difficulty of ball milling to nano-scale, etc., and achieve the effect of avoiding agglomeration and improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

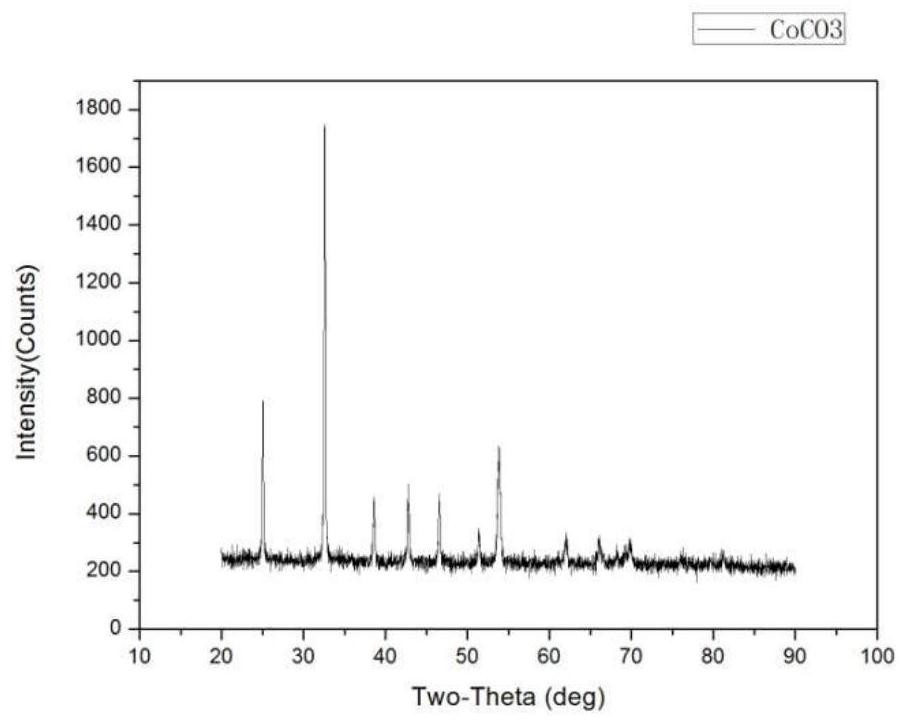

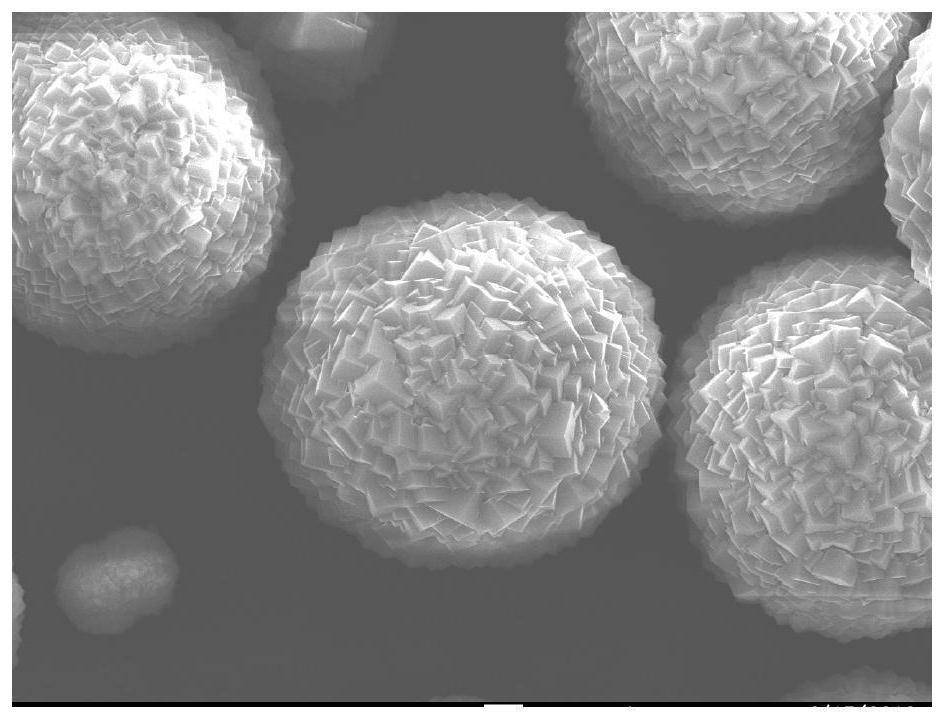

[0027] (1) First weigh 2 grams of red monoclinic cobalt chloride hexahydrate, 4 grams of rod-shaped crystal urea, 20 milliliters of pure deionized water and 60 milliliters of transparent glycerol, and add the above four samples to volume Put the beaker in a 100ml beaker, then place the beaker on a stirrer and put in an olive-shaped magnetic stirring bar to stir thoroughly for 1 hour to obtain a pink solution; then put the above pink solution at room temperature until it is transparent and free of bubbles Put it in a PTFE bottle with a capacity of 100 ml, then place it in a reaction kettle and then transfer it to a high-temperature furnace to provide a high-temperature and high-pressure environment for the solution to allow the sample to undergo a hydrothermal reaction. The parameters of the high-temperature furnace are set to react at a temperature of 120°C For 12 hours, the heating rate is 2°C / min; then wait for the temperature of the reactor to drop to room temperature and th...

Embodiment 2

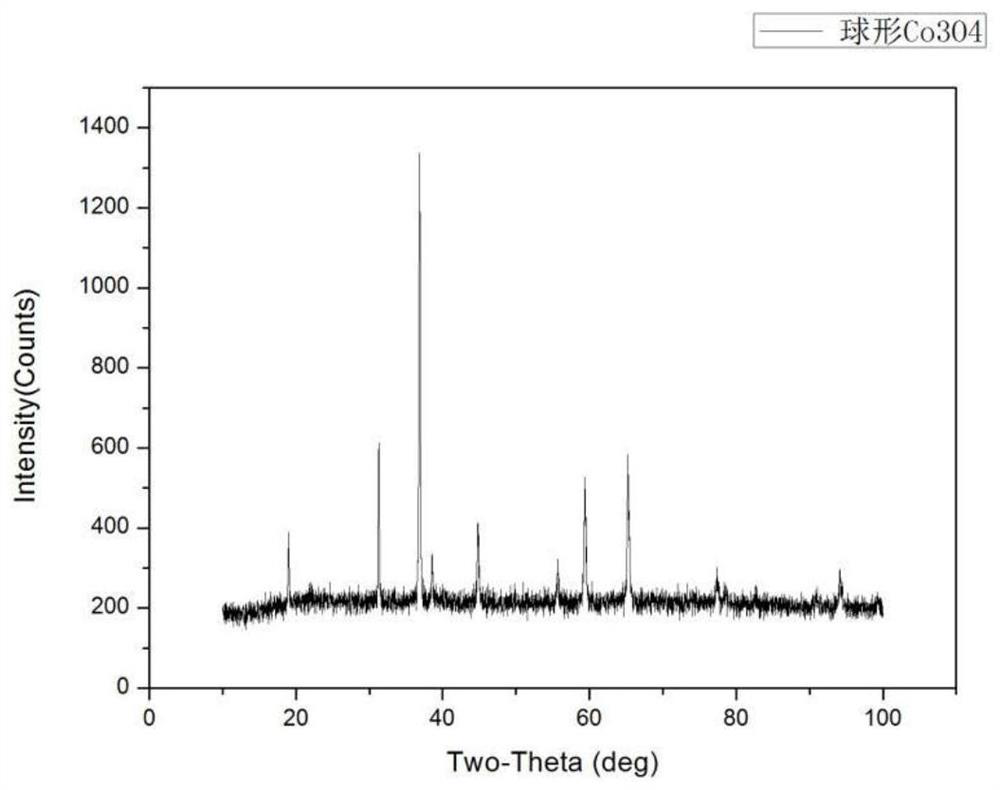

[0031] (1) First weigh 2 grams of red monoclinic cobalt chloride hexahydrate, 4 grams of rod-shaped crystal urea, 20 milliliters of pure deionized water and 60 milliliters of transparent glycerol, and add the above four samples to volume Put the beaker in a 100ml beaker, then place the beaker on a stirrer and put in an olive-shaped magnetic stirring bar to stir thoroughly for 1 hour to obtain a pink solution; then put the above pink solution at room temperature until it is transparent and free of bubbles Put it in a PTFE bottle with a capacity of 100 ml, then place it in a reaction kettle and then transfer it to a high-temperature furnace to provide a high-temperature and high-pressure environment for the solution to allow the sample to undergo a hydrothermal reaction. The parameters of the high-temperature furnace are set to react at a temperature of 160°C 10 hours, the heating rate is 5°C / min; then wait for the temperature of the reactor to drop to room temperature and then f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap