Reinforced environment-friendly building formwork

A green and environmentally friendly construction formwork technology, which is applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems of environmental pollution, discarding, single and limited formwork support angle, etc., and achieve scientific and reasonable structure and safe use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

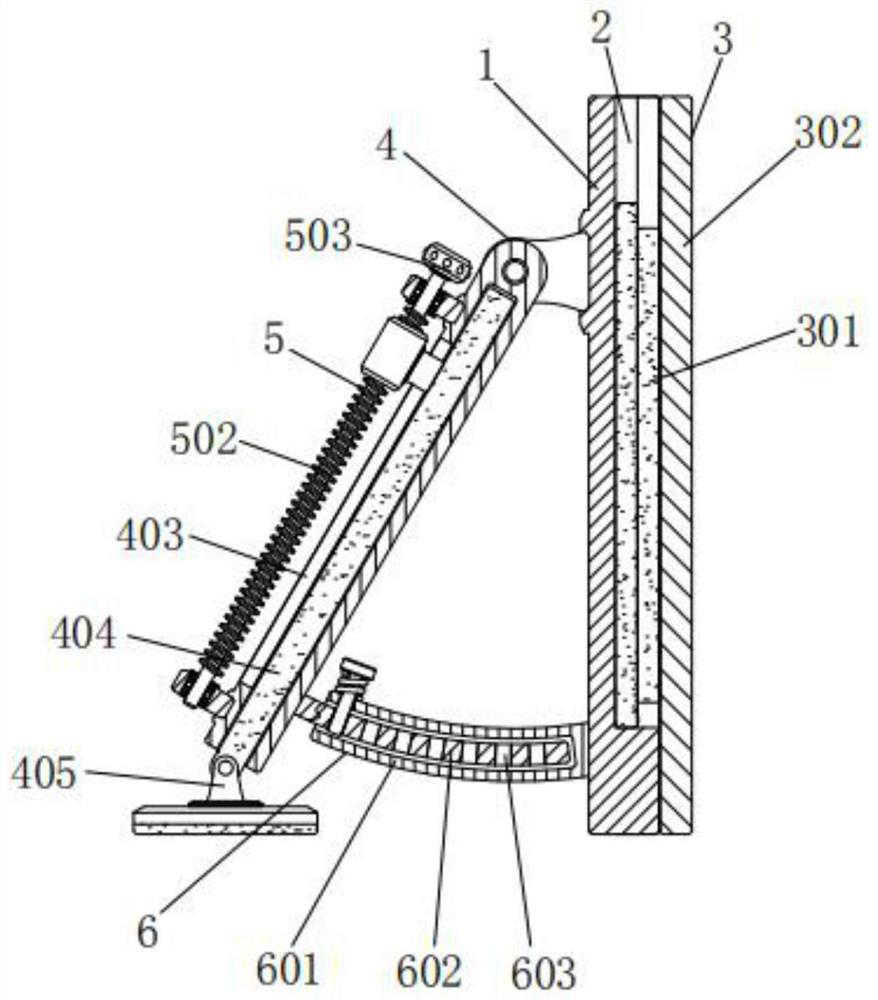

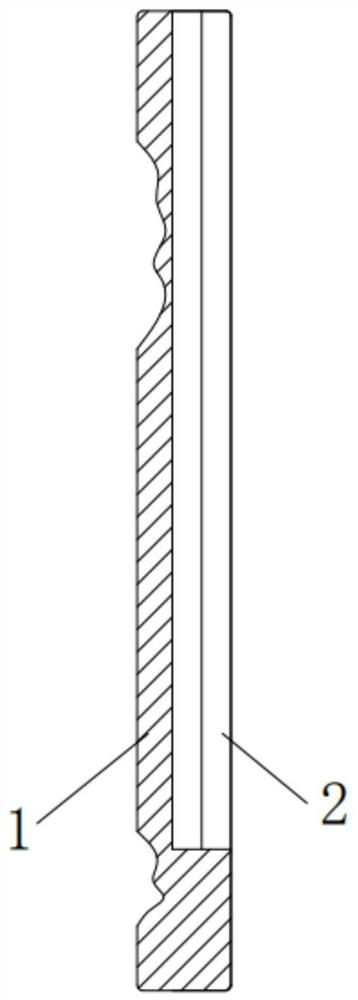

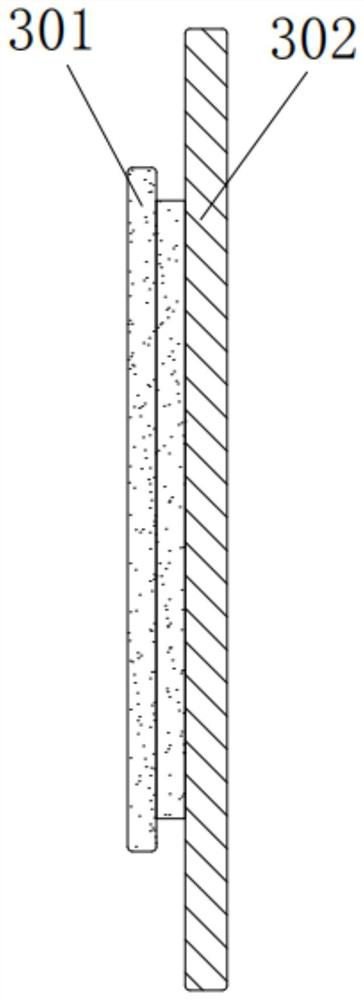

[0040] A reinforced green and environment-friendly building formwork, comprising a board body 1, a T-shaped groove 2 is processed on the right side of the board body 1, and a contact mechanism 3 is provided on the right side of the board body 1, and the contact mechanism 3 includes an aldehyde-free, zero-carbon waterproof and fireproof Environmental protection board 301 and T-shaped block 302, formaldehyde-free zero-carbon waterproof and fire-proof environmental protection board 301 is attached to the right side of board body 1, formaldehyde-free zero-carbon waterproof and fire-proof environmental protection board 301 has anti-deformation, anti-expansion, anti-mildew, anti-corrosion, Acid-base, anti-bending, anti-warping, anti-cracking and green environmental protection, formaldehyde-free, odorless, renewable and recyclable resources, formaldehyde-free and zero-carbon waterproof, fire-proof and environmentally friendly sheet 301 is used for contact with concrete, formaldehyde-fr...

Embodiment 2

[0042] As an option, see figure 1 , 5 And 6, reinforced green and environmentally friendly building formwork, the left side of the board body 1 is provided with a support mechanism 4, and the support mechanism 4 includes a first connecting shaft 401, a first rod body 402, a through groove 403, a second rod body 404, and a second connection The shaft 405 and the horizontal plate 406, the first rod body 402 is connected to the left side of the plate body 1 through the first connecting shaft 401, the left side of the inner wall of the first rod body 402 is processed with a through groove 403, and the inner wall clearance of the first rod body 402 is fitted with a The second rod body 404, so that the second rod body 404 can move up and down on the inner wall of the first rod body 402, the bottom of the second rod body 404 is connected with a horizontal plate 406 through the rotation of the second connecting shaft 405, and the horizontal plate 406 is used to contact with the ground...

Embodiment 3

[0045] As an option, see figure 1 and 5 , a reinforced green building formwork, the left side of the first rod body 402 is provided with a first adjustment mechanism 5, the first adjustment mechanism 5 includes a bearing seat 501, a screw 502, a handle 503, a sleeve 504 and a block 505, and a screw 502 The left side of the first rod body 402 is rotationally connected through two bearing seats 501, a handle 503 is fixedly connected to the top of the screw rod 502, the outer wall of the screw rod 502 is threadedly connected to a crude oil sleeve 504, and a block body 505 is fixedly connected to the right side of the sleeve 504 , the outer wall of the block body 505 is slidingly connected with the inner wall of the through groove 403, the right side of the block body 505 is fixedly connected with the left side of the second rod body 404, when the handle 503 is rotated under force, the handle 503 can drive the screw rod 502 to rotate, When the screw rod 502 rotates, it drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com