Ckjomposite material pultrusion sectional material with A-shaped section

A technology of composite materials and pultruded profiles, which is applied in the field of profile structures, can solve the problems of increasing the self-weight of towers and maintenance costs, and achieve the effects of good designability, strengthened connections, and enhanced connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

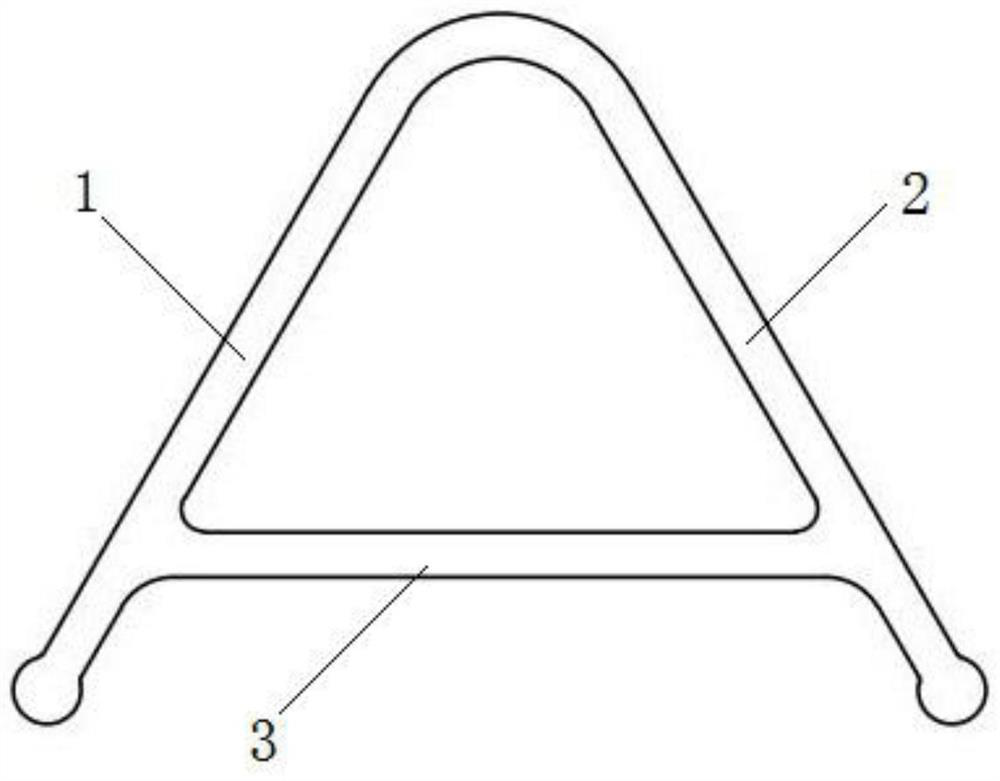

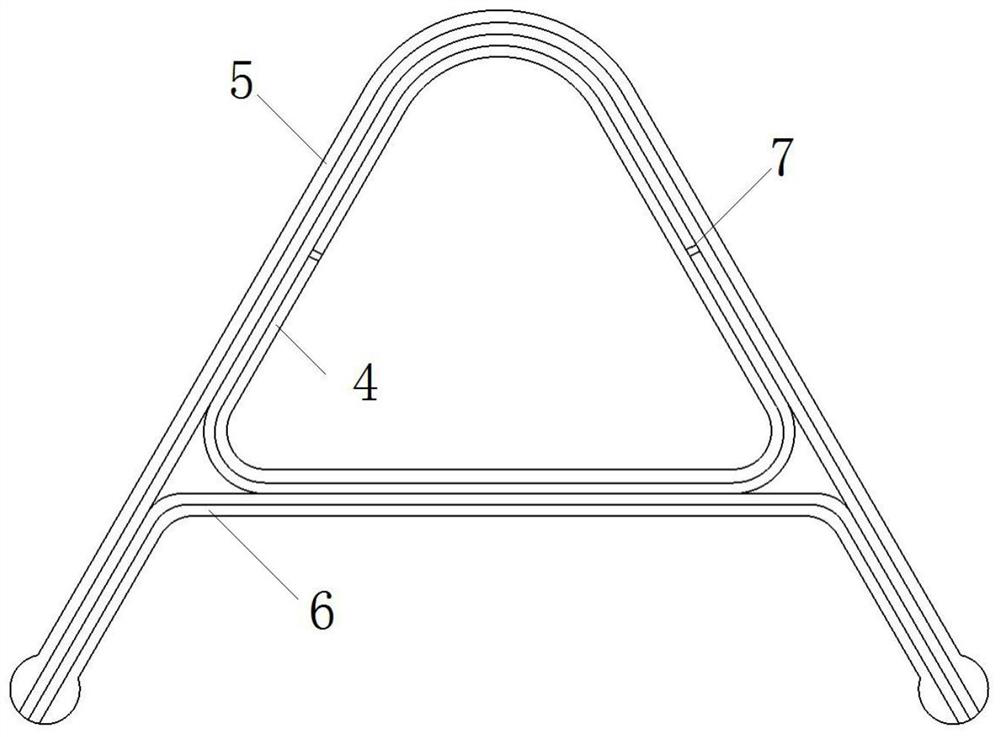

[0017] see Figure 1-2 Describe this embodiment, an A-shaped cross-section composite material pultrusion profile, the profile is an integrated structure, including a left arm 1, a right arm 2 and a cross arm 3, the upper ends of the left arm 1 and the right arm 2 are connected, An included angle is formed, the left arm 1 and the right arm 2 are connected by a cross arm 3, and the left arm 1, right arm 2 and cross arm 3 are connected to form an A-shaped section, and the profile is made of a composite material. The composite material is composed of reinforcing fiber and matrix material, and the profile is pultruded along the vertical direction of the A-shaped section.

[0018] In this embodiment, the interlayer shear stress of the composite material is used to enhance the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com