Carrier rocket previous level recycling system and method and carrier rocket recycling system

A carrier rocket and recovery system technology, applied in the direction of projectiles, self-propelled missiles, offensive equipment, etc., can solve the problem that the upper stage cannot be recovered, and achieve the goal of ensuring internal installation space and payload space, increasing lift, and improving filling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

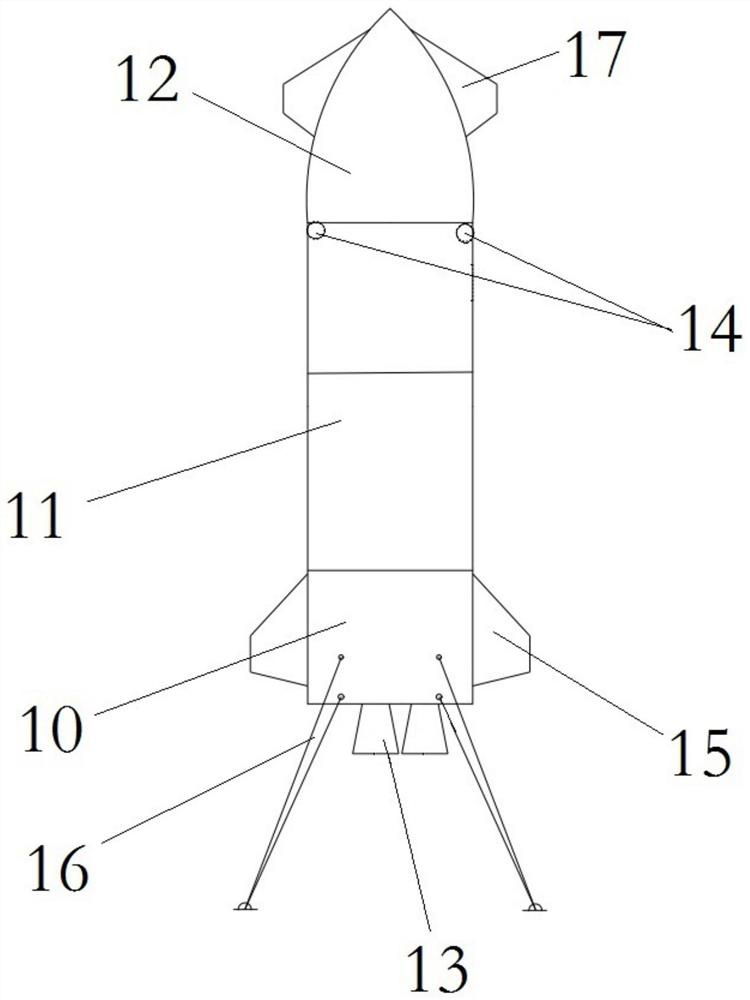

[0046] The upper stage 2 recovery system of the launch vehicle provided by this embodiment, such as figure 1 As shown, it includes: reaction control system, controllable propulsion system, canard 17 and landing support legs; through the reaction control system, the motion attitude of the upper stage is adjusted and controlled to realize de-orbit deceleration of the upper stage; after entering the atmosphere, the upper stage passes The head of the reaction control system and the aerodynamic rudder keep the head facing forward and tilting; the deflection of the aerodynamic control rudder on the canard and tail provides lift to the upper stage, and then adjusts the speed of the descent process; when landing on the ground, Buffering and support are performed by the landing support legs; through the combined use of the above structures, the present invention realizes the recovery of the upper stage 2 of the launch vehicle, and meets the needs of the space launch market such as great...

Embodiment 2

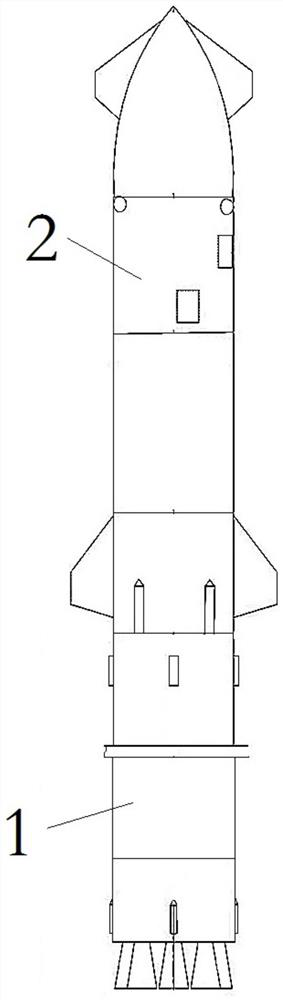

[0054] The recovery system of the launch vehicle provided by this embodiment, such as figure 2 As shown, it includes the booster level 1 recovery system and the upper level 2 recovery system; the upper level 2 recovery system is the same as in embodiment 1. The booster stage 1 recovery system is described in detail below.

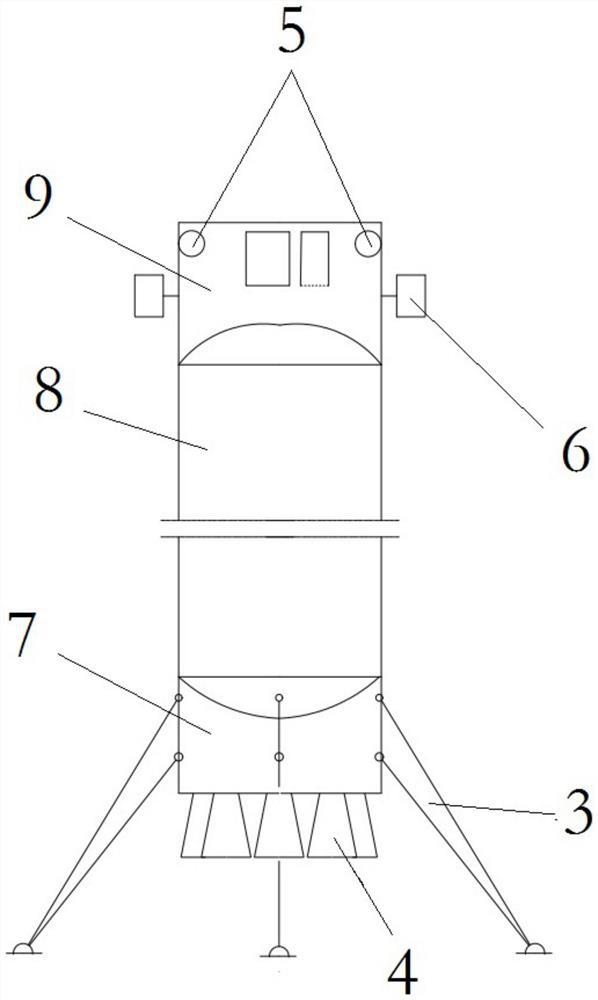

[0055] Such as image 3 As shown, the booster stage 1 is sequentially provided with a first tail section 7, a first storage tank 8 and an interstage section 9 from bottom to top; the lower end of the first tail section 7 is provided with a first controllable propulsion system 4 The rocket motor has a plurality of rocket motors, wherein there are also redundant rocket motors.

[0056] At the same time, the lower end of the first tail section 7 is also provided with a first landing support leg 3; the outer surface of the first tail section 7 is provided with a thermal protection system to prevent the booster stage 1 from being aerodynamically heated and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com