Intelligent production scheduling system based on genetic algorithm

A genetic algorithm and production system technology, applied in the field of intelligent production scheduling, can solve the problems of low accuracy rate of manual production planning and the inability to change the production scheduling plan in a timely manner, achieving short calculation time, high accuracy of production scheduling, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

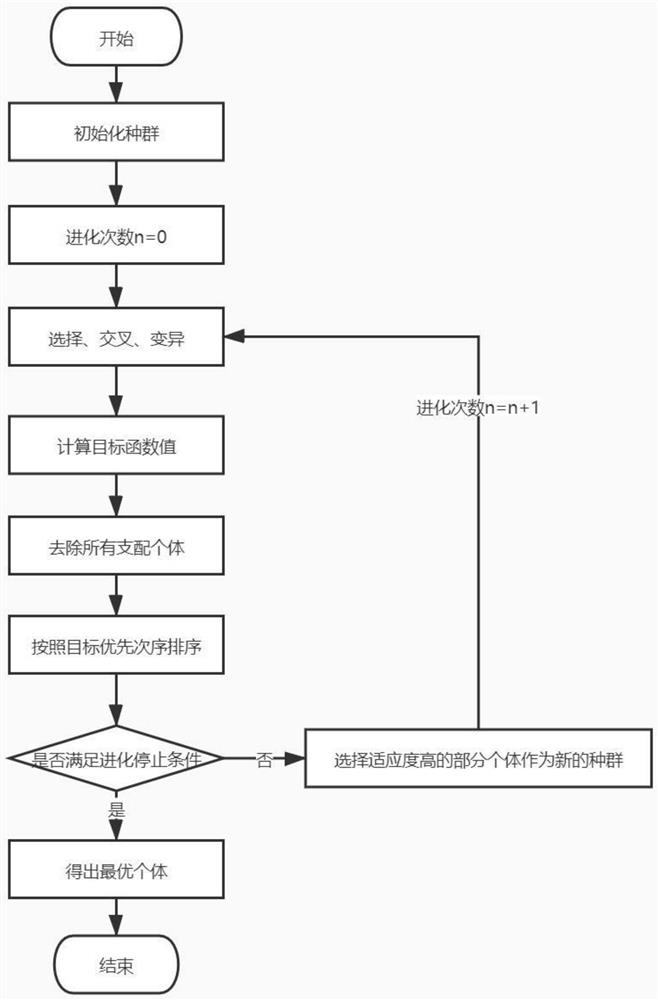

[0046] The intelligent production scheduling system based on genetic algorithm of the present invention at least comprises the following steps:

[0047] Step 1. Randomly generate a population of a certain size. Individuals in the population are composed of two chromosomes. The genes of chromosome 1 are the random sequence combination of all tasks and optional equipment. The genes of chromosome 2 are the daily working hours of overtime-capable equipment. The time is randomly generated;

[0048] Step 2. Randomly select two parents from the population for gene recombination. The recombination methods are divided into the following four types:

[0049] Chromosome 1 exchange in both parents;

[0050] Partial gene exchange of chromosome 1 in both parents, chromosome 2 unchanged;

[0051] Partial gene exchange of chromosome 2 in both parents, chromosome 1 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com