A blind element filling method and system

A filling method and filling system technology, applied in the field of image processing, can solve the problems of large computational load, poor response performance, affecting imaging quality, etc., and achieve the effects of less computational resource occupancy, good consistency, and low computational load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0046] The infrared gun sight can observe the infrared visual field through the eyepiece to display the living target, and provide the user with the infrared imaging information of the living target under the condition of poor visual conditions. Carry out filling elimination to improve image quality. The present invention combines the technical development status of uncooled infrared detectors applied to infrared gun sights in recent years, and a blind element filling method and system invented based on an infrared gun sight.

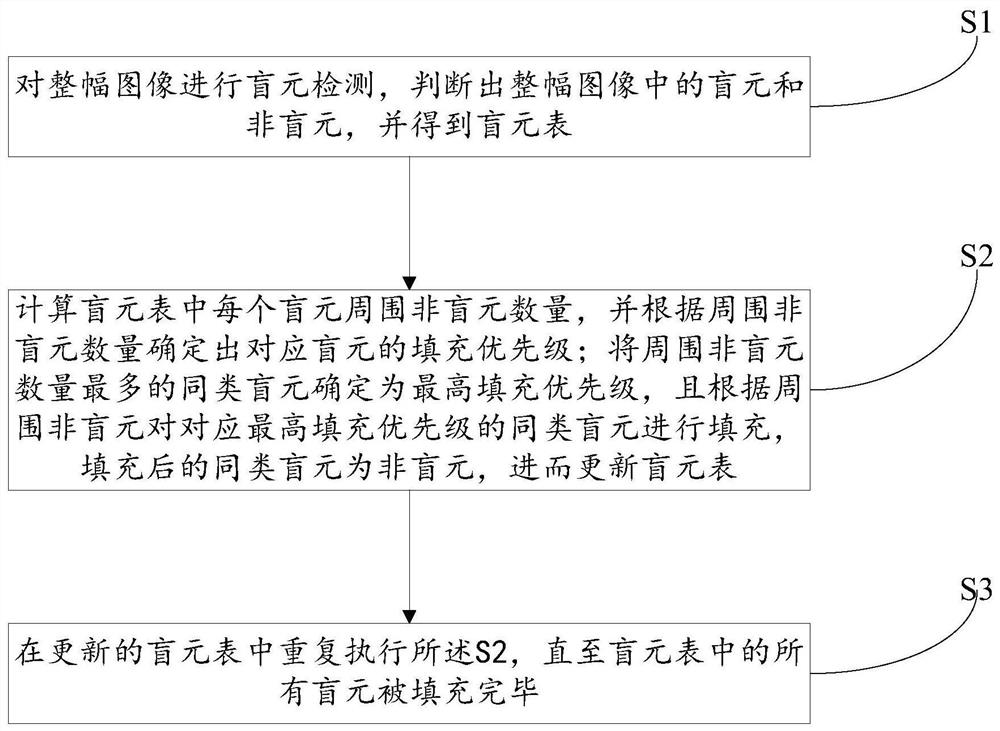

[0047] Such as figure 1 As shown, a blind element filling method includes the following steps,

[0048] S1, perform blind element detection on the entire image, determine blind elements and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com